Ethanol gas sensor based on ZnO hollow flower ball and CdO nano-particle composite nanomaterial and preparation method of ethanol gas sensor

A technology of composite nanomaterials and gas sensors, which is applied in the fields of analyzing materials, material resistance, and material analysis through electromagnetic means, and can solve problems such as poor gas sensitivity characteristics and lower detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

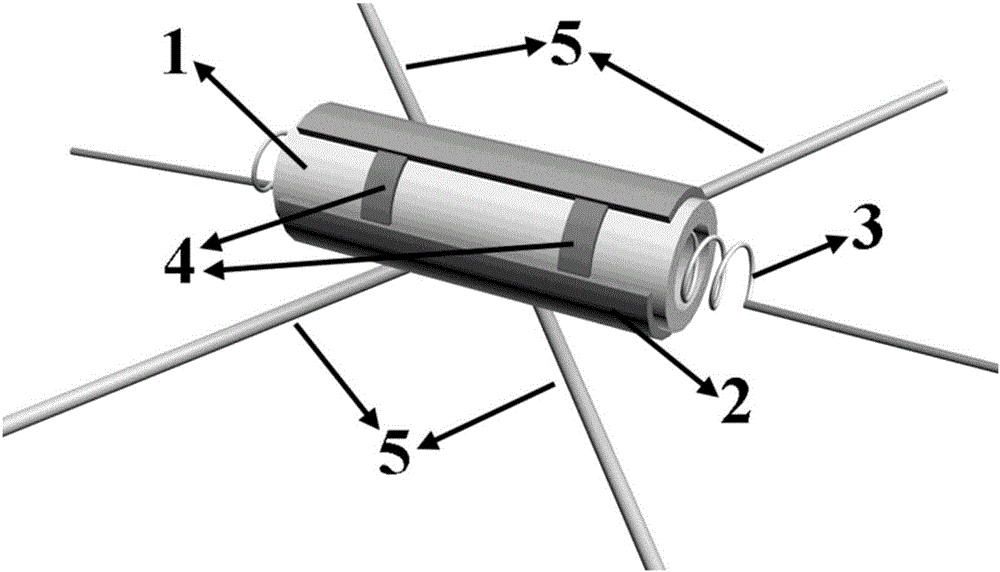

[0035] With the Cd:Zn molar ratio of 0.44:100 (this ratio is within the scope of the raw material dosage described in the summary of the invention, right? Yes), the ZnO hollow flower bulb and CdO nanoparticle composite nanomaterial prepared as a sensitive material to make an ethanol gas sensor, the specific The production process is as follows:

[0036] 1. First, 30mg of ZnO hollow curd powder, 0.003g of Cd(NO 3 ) 2 4H 2 O(cadmium nitrate tetrahydrate), 0.006g of CH 4 N 2 Add S (thiourea) to 30mL DMF one by one, keep stirring until it is completely dissolved, then add 300μL isopropanol to the above solution, continue stirring for 10min, and then sonicate for 30min after stirring;

[0037] 2. The above solution was hydrothermally reacted at 160°C for 10h, cooled to room temperature, and the resulting precipitate was washed with deionized water and ethanol alternately for 7 times, then dried at 80°C, and then calcined at 500°C for 2h , finally obtained the composite nanomat...

Embodiment 2

[0041] Using Cd:Zn molar ratio of 0.88:100 (this ratio is within the range of the amount of raw materials described in the summary of the invention? Yes), the ZnO hollow flower ball and CdO nanoparticles composite nanomaterials are used to make ethanol gas sensors, and the specific manufacturing process as follows:

[0042] 1. First, 30mg of ZnO hollow curd powder, 0.006g of Cd(NO 3 ) 2 4H 2 O(cadmium nitrate tetrahydrate), 0.012g of CH 4 N 2 Add S (thiourea) to 30mL DMF one by one, keep stirring until it is completely dissolved, then add 300μL isopropanol to the above solution, continue stirring for 10min, and then sonicate for 30min after stirring;

[0043] 2. The above solution was hydrothermally reacted at 160°C for 10h, cooled to room temperature, and the resulting precipitate was washed with deionized water and ethanol alternately for 7 times, then dried at 80°C, and then calcined at 500°C for 2h , finally obtained the composite nanomaterial of ZnO hollow curd and C...

Embodiment 3

[0047] Using Cd:Zn molar ratio 2.64:100 (this ratio is within the range of raw materials used in the summary of the invention? Yes), the ZnO hollow flower ball and CdO nanoparticles composite nanomaterials are used to make ethanol gas sensors, and the specific manufacturing process as follows:

[0048] 1. First, 30mg of ZnO hollow curd powder, 0.012g of Cd(NO 3 ) 2 4H 2 O (cadmium nitrate tetrahydrate), 0.024 g of CH 4 N 2 Add S (thiourea) to 30mL DMF one by one, keep stirring until it is completely dissolved, then add 300μL isopropanol to the above solution, continue stirring for 10min, and then sonicate for 30min after stirring;

[0049] 2. The above solution was hydrothermally reacted at 160°C for 10h, cooled to room temperature, and the resulting precipitate was washed with deionized water and ethanol alternately for 7 times, then dried at 80°C, and then calcined at 500°C for 2h , finally obtained the composite nanomaterial of ZnO hollow curd and CdO nanoparticles;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com