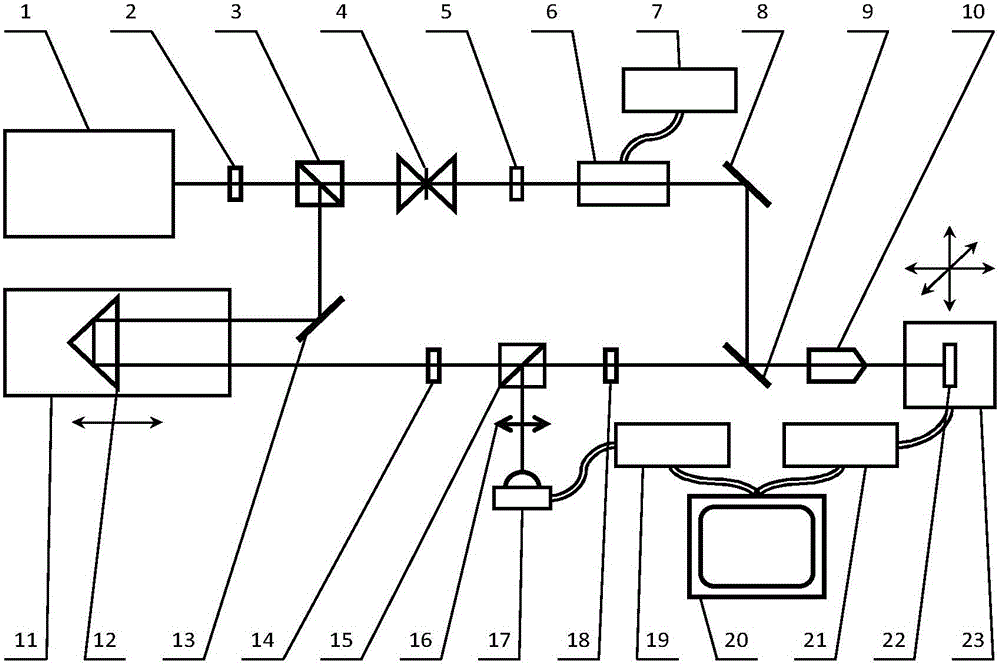

Heat-conductivity scanning system based on pumping-detection heat reflection technology

A scanning system and thermal conductivity technology, which is applied in the field of thermal conductivity testing, can solve the problems of not being able to satisfy the thermal conductivity distribution and not being able to obtain the thermal conductivity distribution of the sample surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical idea of the thermal conductivity scanning system based on the pumping detection heat reflection technology provided by the present invention is: the computer controls the three-dimensional electric mobile platform to move up, down, left, and right in two dimensions perpendicular to the incident direction of the laser beam. The current position information and conduct a pumping detection measurement, the lock-in amplifier collects the pumping detection signal output by the photodetector in real time, the computer obtains the output signal of the lock-in amplifier in real time, and the computer extracts the amplitude signal component of the lock-in amplifier output signal, and simultaneously controls the The three-dimensional electric moving table moves back and forth in the direction parallel to the incident laser beam, and stops when the amplitude signal component is maximum. This process is carried out before each pumping detection measurement.

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com