Rapid determination method for moisture content in production of papermaking-process reconstituted tobaccos

A technology for rapid determination of reconstituted tobacco leaves, applied to measuring devices, weighing by removing certain components, instruments, etc., can solve problems such as long detection time, short infrared wavelength, and sample damage, and achieve reproducibility of measurement results High performance, fast detection response speed, and low sample demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

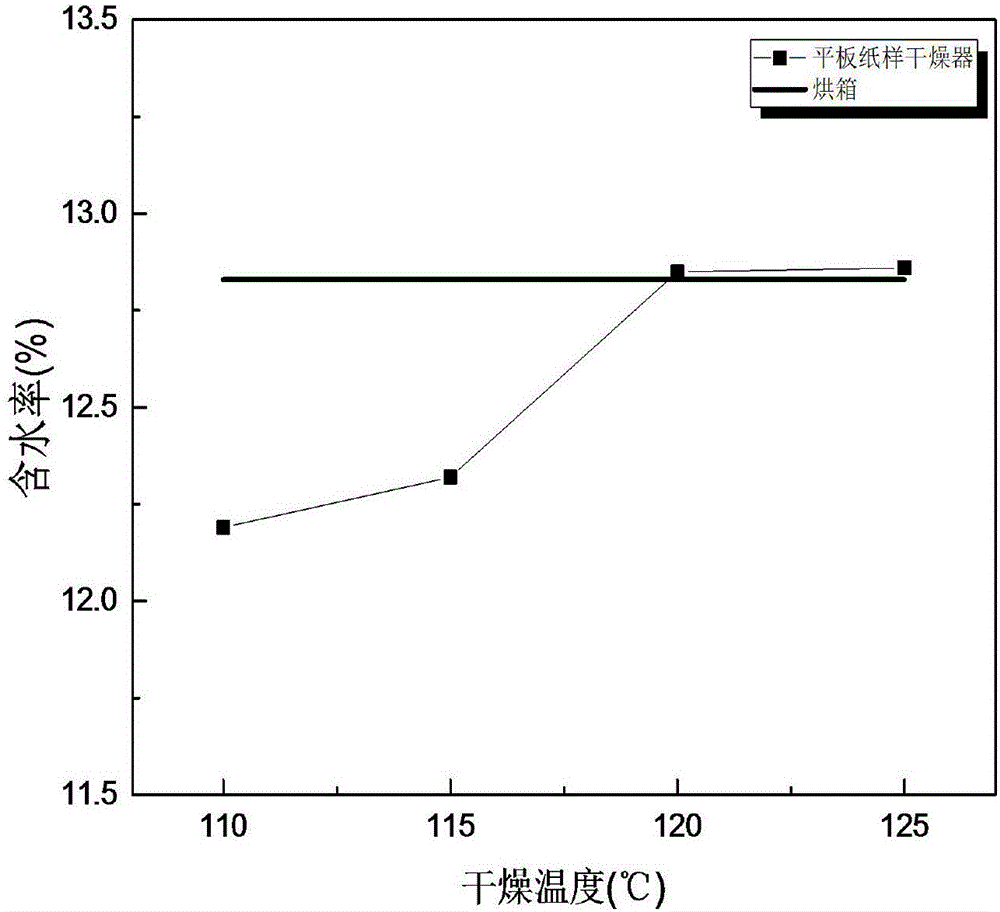

[0021] In order to test the optimum drying temperature of the flat paper dryer for fast and efficient measurement of the moisture content of the finished product, during the stable production period of a certain type of reconstituted tobacco leaf product by the papermaking method, the slit products are transported to the drying cylinder for drying. By adjusting the rotation speed of the drying cylinder and The steam pressure controls the moisture of the product, and then the product is transported to the cabinet. Under the joint action of the temperature and humidity of the external environment and its own moisture, the moisture of the product reaches a natural balance, and the samples to be tested (40mm×40mm diamond-shaped thin slices, 5 pieces One group, 8 groups in total); set the working temperature of the PL7-C flat paper sample dryer to 110°C, 115°C, 120°C and 125°C respectively, and set the working temperature of the digital display blast drying oven to 105°C; 8 groups o...

Embodiment 2

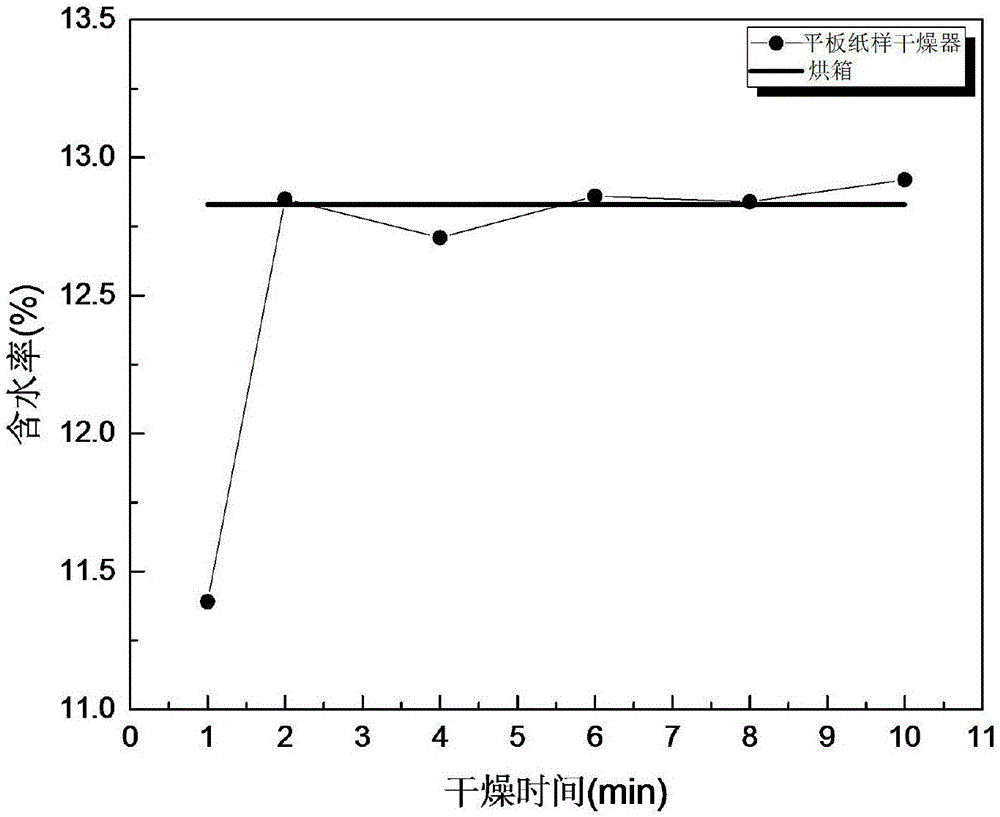

[0032] According to Example 1, it can be known that the moisture content of the sample can be quickly measured by using a flat paper-like dryer at 120 ° C. In order to find the best drying time at this temperature, the same sample as in Example 1 (40mm * 40mm diamond-shaped finished sheet, 5 pieces) One group, 12 groups in total); set the control temperature of the PL7-C flat paper sample dryer to 120°C (±1°C); number the 12 groups of samples and weigh their mass m 0 (accurate to 0.001g), at a working temperature of 120°C, use a flat paper dryer to dry the sample at different drying times (1min, 2min, 4min, 6min, 8min, 10min), in order to ensure the accuracy of the experimental data , take two groups of samples at each drying temperature for parallel experiments, and use an analytical balance to quickly measure the mass of the dried samples m 1 (accurate to 0.001g); the test results are calculated according to the following formula:

[0033]

[0034] Table 2 shows the test...

Embodiment 3

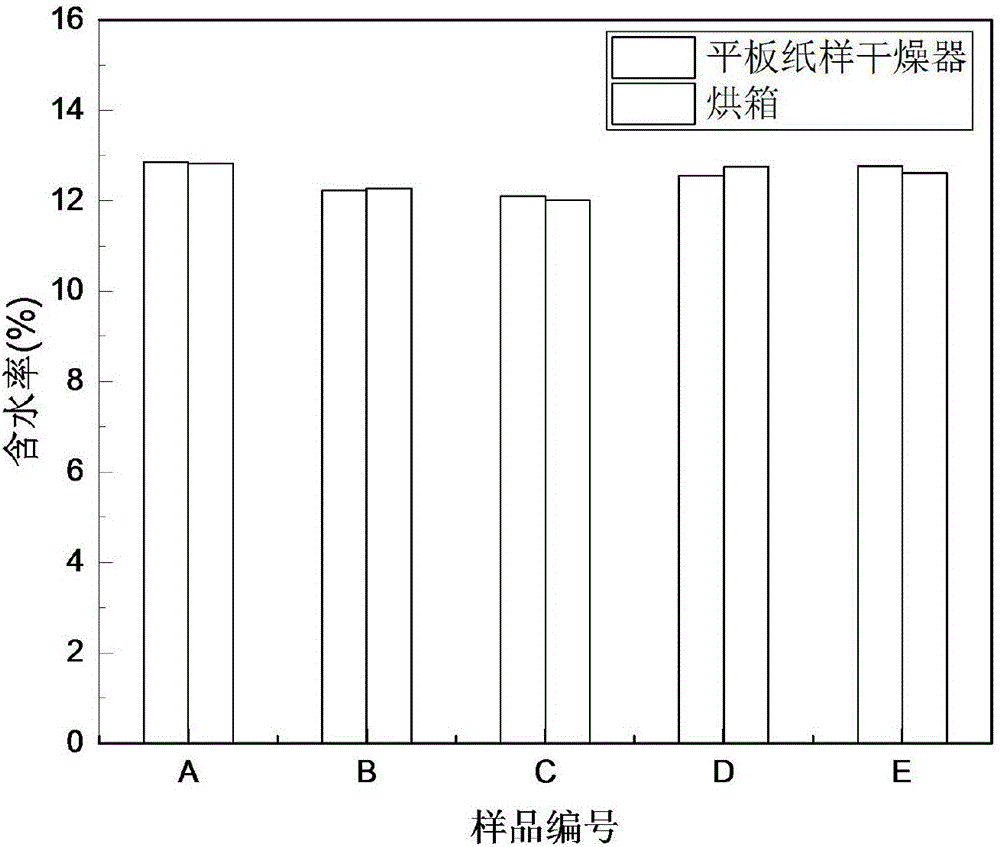

[0039] In order to verify that the invention is effective for the rapid measurement of moisture content of different types of reconstituted tobacco products, five different types of reconstituted tobacco products (40mm× 40mm rhombus sample, 5 pieces in a group), in order to ensure the accuracy of the experimental data, two groups of each sample were used for rapid detection of moisture content using a flat paper sample dryer; the working temperature of the PL7-C flat paper sample dryer was set to 120 °C (±1 °C), the working temperature of the digital display blast drying oven equipment is set to 105 °C; number the 10 groups of samples, and weigh their masses respectively m 0 (accurate to 0.001g), put the samples on the drying plate of a flat paper dryer and dry them for 2 minutes, and use an analytical balance to quickly measure the mass of the dried samples m 1 (accurate to 0.001g); In addition, take 2 samples (2-3g, accurate to 0.001g) of 5 different types of products and we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com