A method for rapid detection of strength of on-site autoclaved aerated concrete blocks

A concrete block, autoclaved gas filling technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, weighing by removing certain components, etc., can solve the problem that product quality cannot be guaranteed and it is difficult to judge Consistency of samples sent for inspection, safety hazards of engineering quality control and other issues, to achieve the effect of shortening the detection cycle, simple operation, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

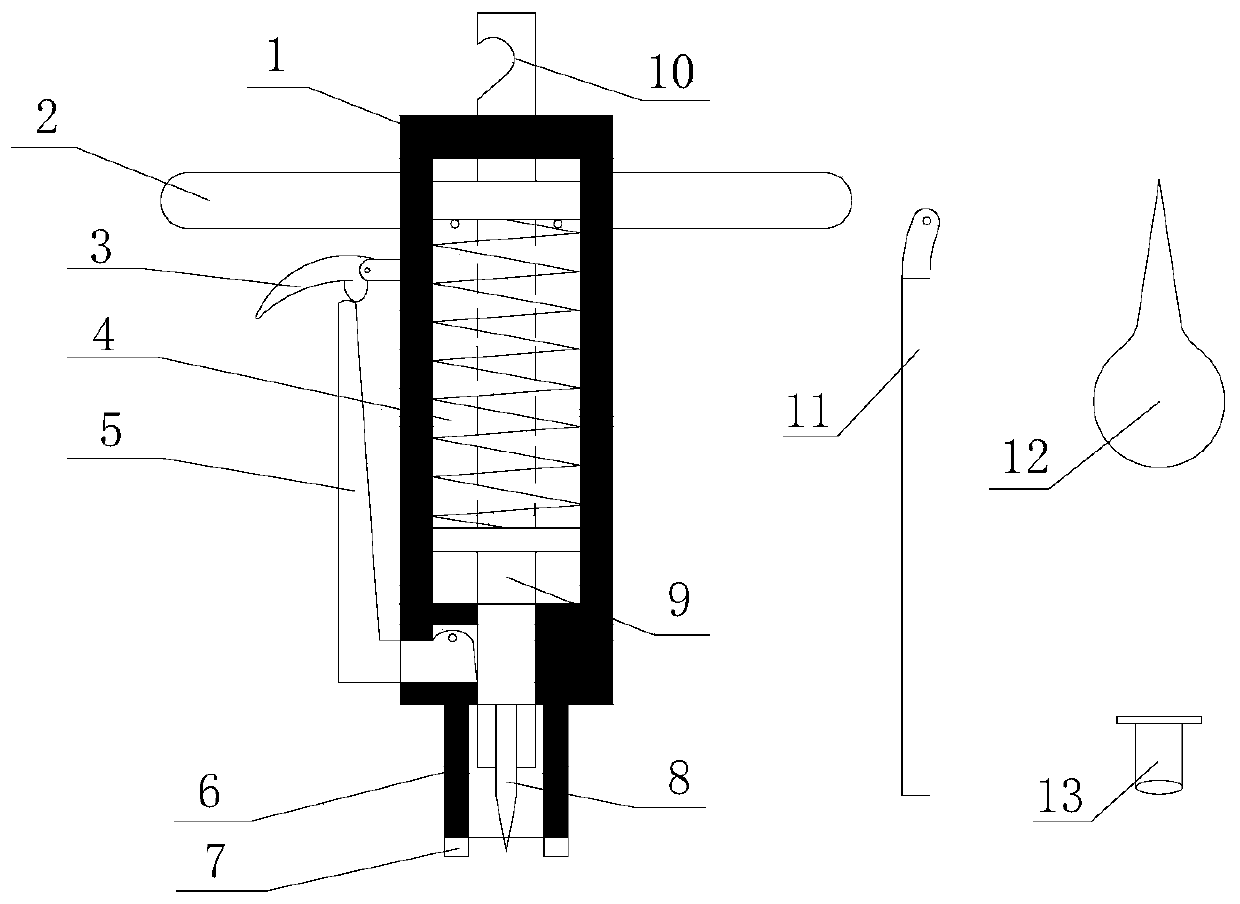

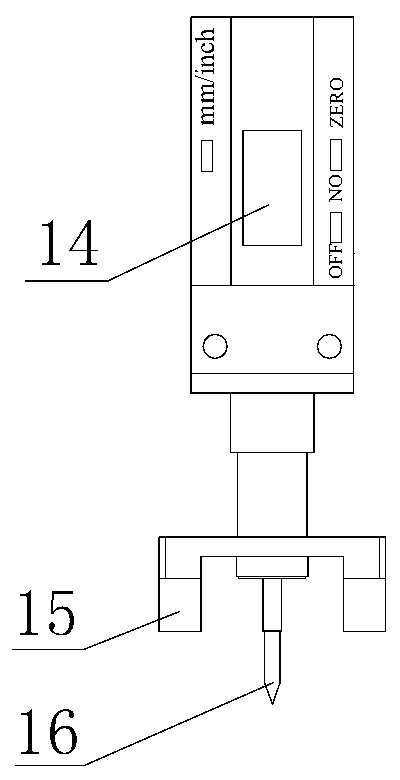

[0029] Such as figure 1 and 2 As shown, this embodiment is a test device for on-site detection of the strength of autoclaved aerated concrete blocks, including a housing 1, a handle 2, a trigger 3, a spring 4, a hook 5, a nail stand 6, a first flat head 7. Measuring nail 8, penetrating rod 9, booster groove 10, booster rod 11, blower 12, screw nut tightening wrench 13, digital display LCD screen 14, flat head 15 and measuring head 16.

[0030] Such as figure 1 As shown, the penetration strength detector includes a housing 1, a handle 2, a trigger 3, a spring 4, a hook 5, a nail base 6, a first flat head 7, a nail 8, a penetration rod 9, and a force concave Groove 10, afterburner rod 11, blower 12, measuring nail seat nut tightening wrench 13. During detection, insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com