Device and method for testing resolution of reflector

A mirror and resolution technology, applied in the field of optical testing, can solve the problem of not finding the testing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

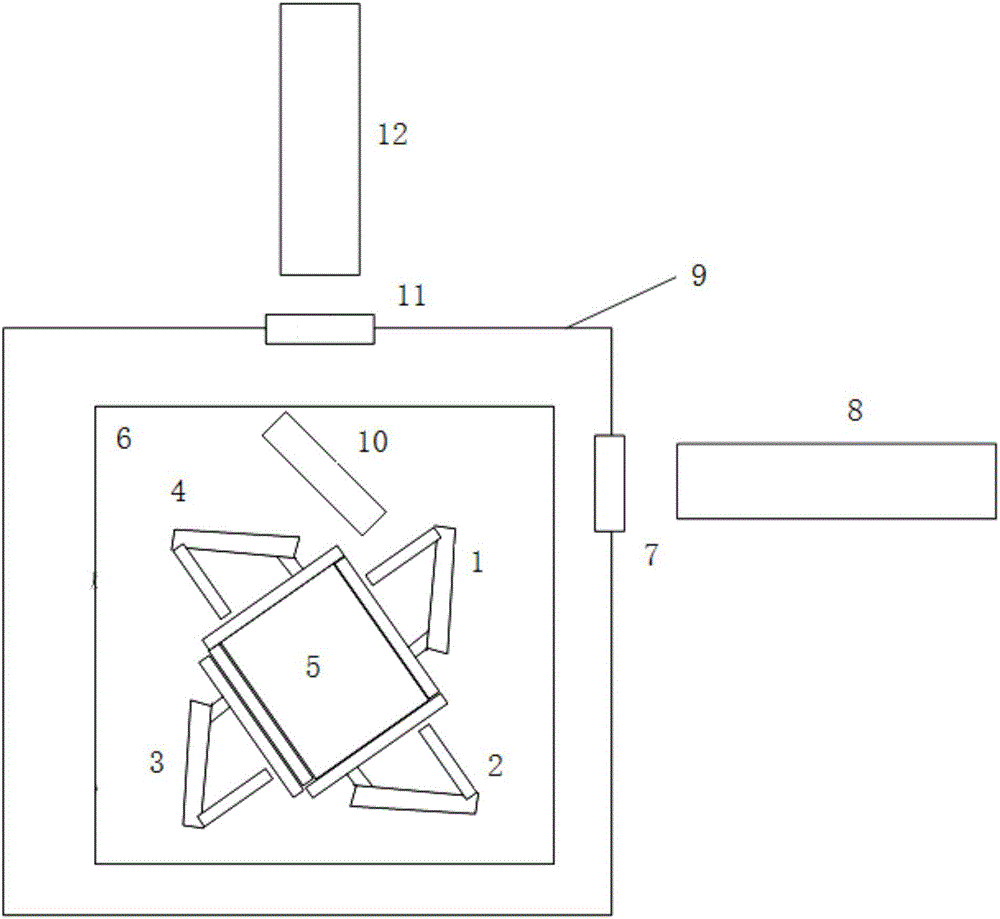

[0020] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0021] The specific test method and process are as follows:

[0022] 1) Put the product under test (mirror 1, mirror 2, mirror 3 and mirror 4) on the electric control turntable and fix the product.

[0023] 2) Start the high and low temperature box, and lower the high and low temperature box to -55°C;

[0024] 3) Simultaneously activate the heating film on the inner surface of the light window on the high and low temperature box to keep the temperature of the inner surface of the light window consistent with the outside temperature of the high and low temperature box.

[0025] 4) Move the standard mirror to the position shown in the figure through the electric control guide rail, and the standard mirror is 45° with the collimator and the front mirror.

[0026] 5) Turn on the collimator light source, the parallel light emitted by the collimator is reflected by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com