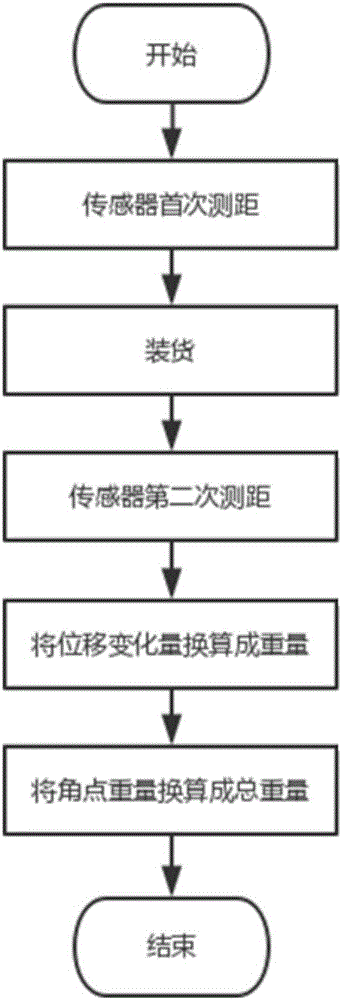

Method for measuring weight of railway freight car

A railway freight car and weight measurement technology, which is applied to weighing equipment, special scales, and measuring devices using elastically deformable parts, can solve the problems of low weight measurement accuracy, harsh use environment requirements, and high cost, and achieve measurement results Precise, highly automated, and inexpensive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

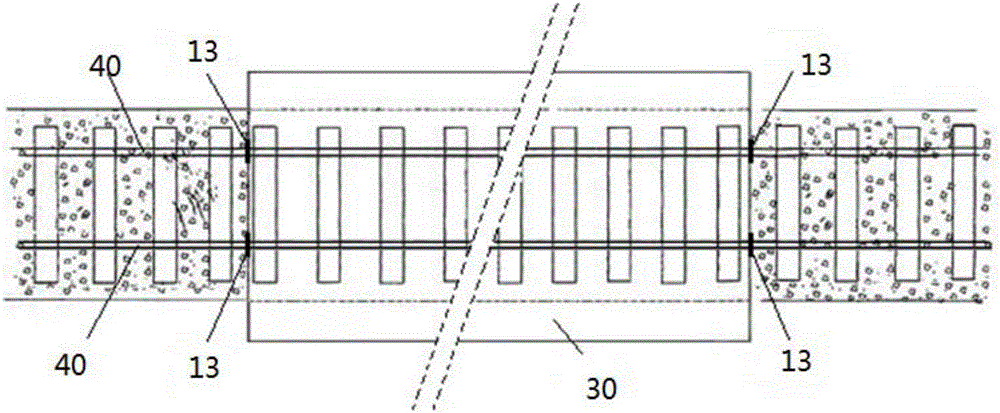

[0028] Such as Figure 1 to Figure 2 as shown in

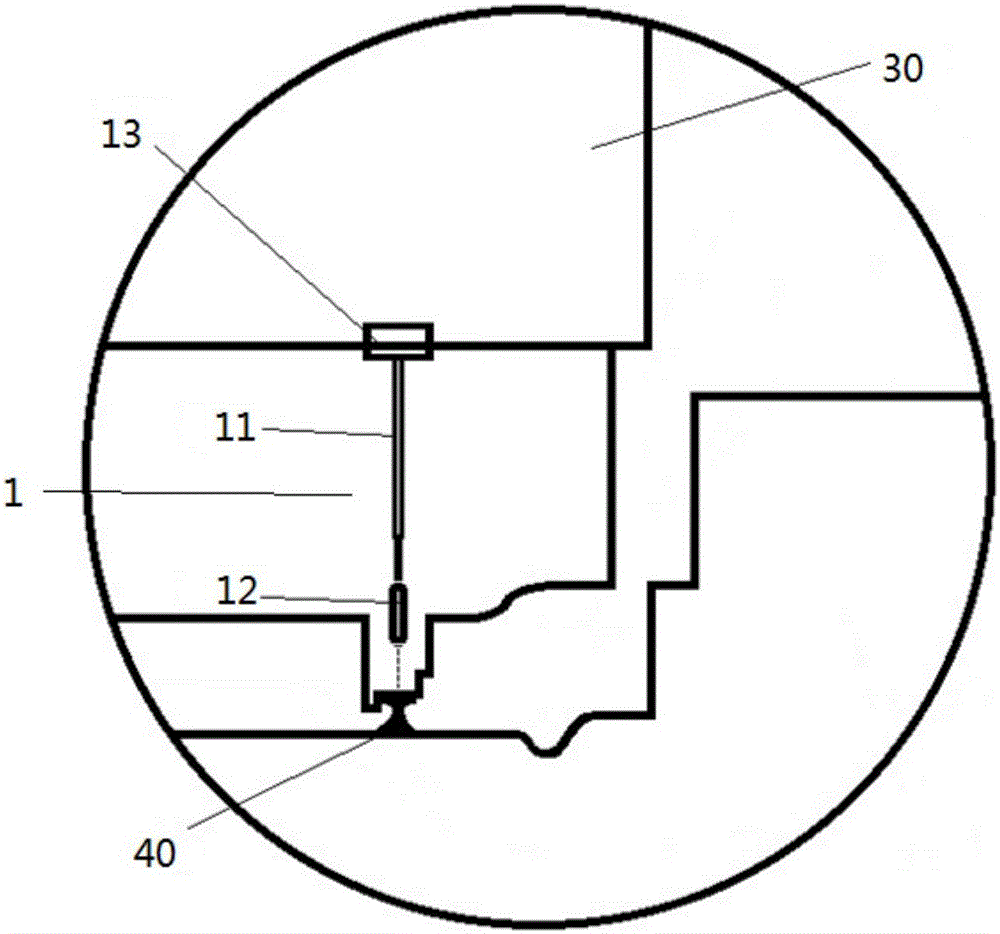

[0029] According to the method for weight measurement of railway freight cars of the present invention, a single truck carriage 30 is used as a unit to realize the method of weight measurement, and four sensor supports 10 and lasers respectively installed on the sensor support 10 are arranged at the bottom of the single carriage. The distance measuring sensor 20; the sensor support member 10 includes the sensor support rod main rod part 11, the laser ranging sensor fixing part 12 installed on one end of the sensor support rod main rod part 11 by welding or bolting or integrally formed and installed on the sensor support rod The ground vertical alignment mechanism 13 at the other end of the main rod portion 11 is fixed on the front and rear corners of the truck compartment 30 directly above the rail 40 by han...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com