Tempering control device for cutting torch

A control device and cutting torch technology, which is applied in the direction of burner safety device, gas fuel burner, combustion method, etc., can solve the problems of unfamiliar switch direction of the knob switch, long closing cycle, leather tube burn, etc., to avoid safe production Accident, easy installation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

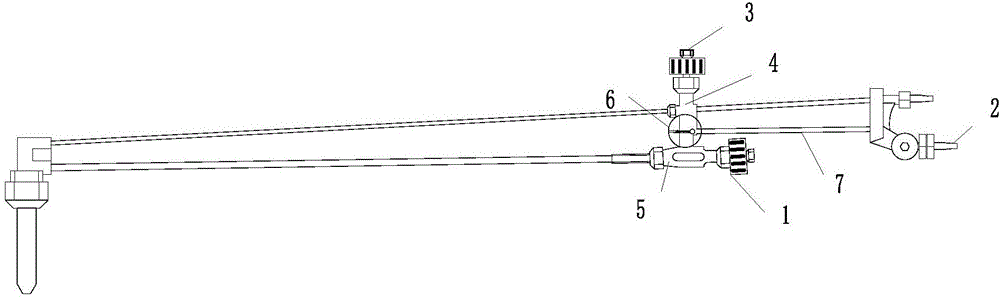

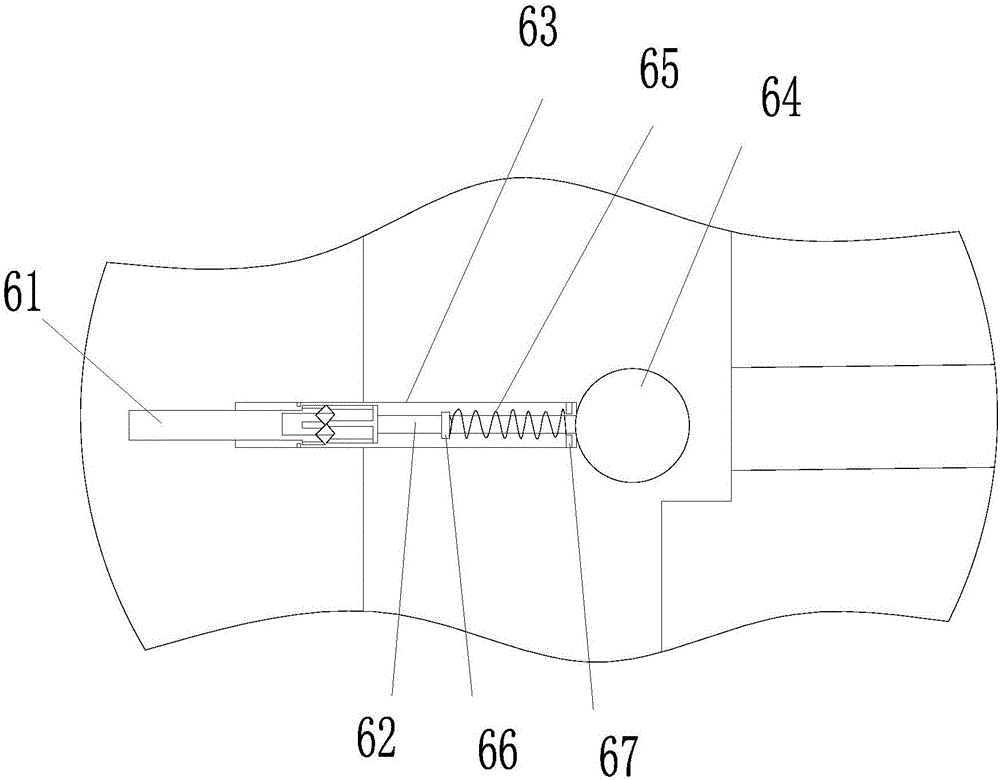

[0018] figure 1 and 2 As shown, a cutting torch tempering control device 6 is arranged in the cutting torch to realize explosion-proof, including a mixed oxygen switch 1, an acetylene gas switch 2, a high-pressure oxygen switch 3, a high-pressure oxygen tube 4, an acetylene gas tube 7 and oxyacetylene The mixing tube 5, the tempering control device 6 is arranged at the junction of the high-pressure oxygen tube 4 and the oxyacetylene mixing tube 5, which includes a fixing seat 63, and the fixing seat 63 is provided with a first push rod 61 and a second Two push rods 62, the end of the second push rod 62 is provided with a ball valve 64, pushes the first push rod 61, and the second push rod 62 can drive the ball valve 64 to move so that the ball valve 64 will The acetylene gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com