Compound glass steel tube easy to insert and connect

A glass fiber reinforced plastic, composite technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of increasing the production cost of molds, overlapping waste of glass steel pipes, and workers being scratched by burrs, etc., to improve the use of products. rate, is conducive to laying, and avoids the effect of unevenness at the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

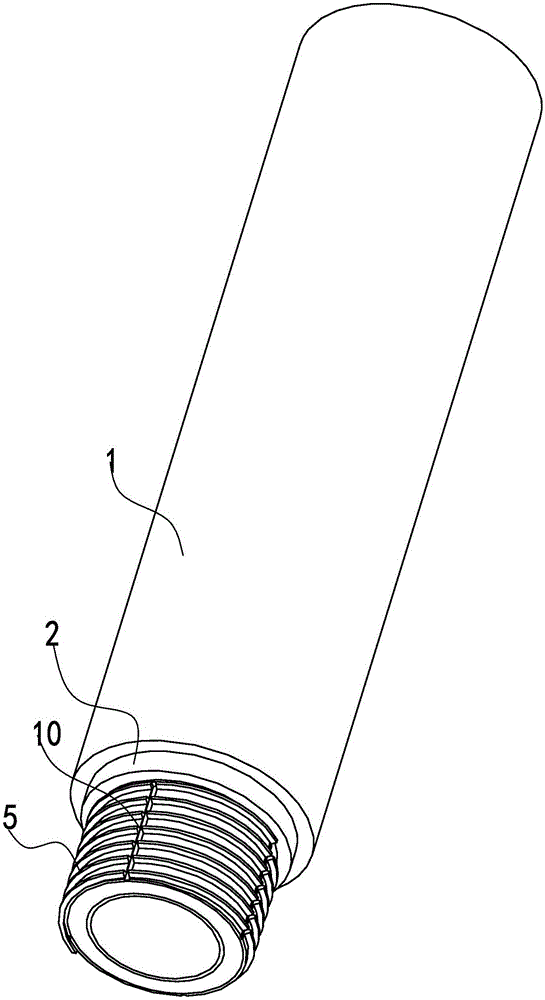

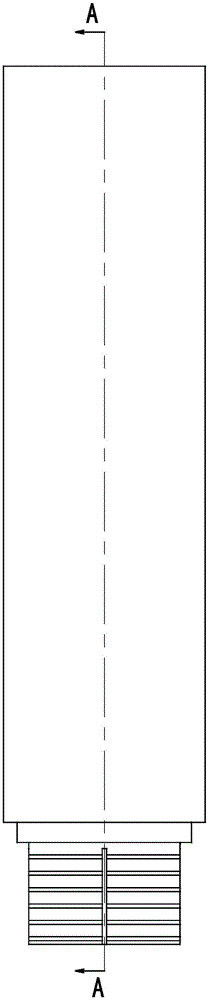

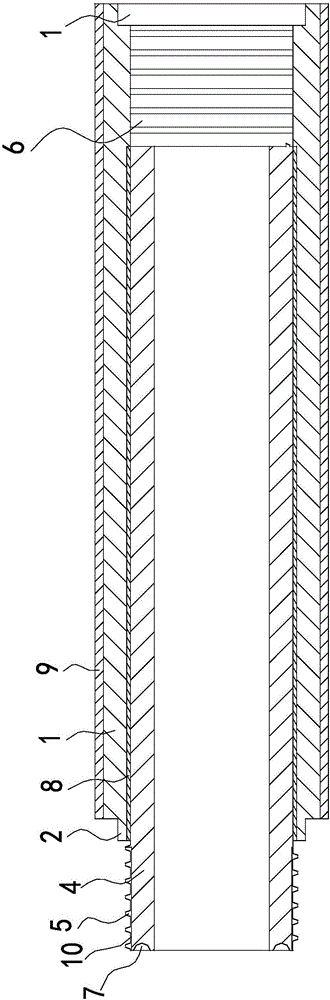

[0034] Such as Figure 1 to Figure 3 , a composite glass steel pipe that is easy to plug in, including a pipe sleeve 1, the pipe sleeve 1 is made of glass fiber reinforced plastic, and a ring of bosses 2 is arranged on the inner ring side of the left end surface of the pipe sleeve 1. A ring groove 3 is provided on the inner ring side of the right end face of the sleeve 1 , and the inner surface of the ring groove 3 is adapted to the outer surface of the boss 2 .

[0035] The inside of the sleeve 1 is penetrated along the axial direction of the sleeve 1 with a protection tube 4 directly in contact with the cable. The length of the protection tube 4 is the same as that of the sleeve 1. The left end surface of the protection tube 4 is located The left side of the left end face of the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com