Oil cooling bearing

A bearing and oil cooling technology, applied in the direction of bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of cooling oil sinking, aggravated sliding friction surface wear, poor lubrication, etc., to maintain a stable friction coefficient and avoid grinding shoes Or the effect of burning tiles and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] An oil-cooled bearing such as Figure 4 and Figure 5 As shown, it includes a bearing cooling structure, a bearing seat 501, a bearing cover 502, a bearing bush 503, a cooling oil tank 504, an oil pump 505, a cold oil inlet 506 and a hot oil drain 507; the bearing cover 502 is located above the bearing seat 501, and the The bearing bush 503 is fixed on the bearing seat 501, and the inner diameter side of the bearing bush 503 is provided with a cooling oil groove 504 along the axial direction, and the middle part of the cooling oil groove 504 is provided with an oil inlet hole 5041, and the oil inlet hole 5041 communicates with the cooling oil inlet 506, the other end of the cold oil inlet 506 is connected to the oil pump 505, and the two ends of the bearing bush 503 are provided with hot oil drains 507.

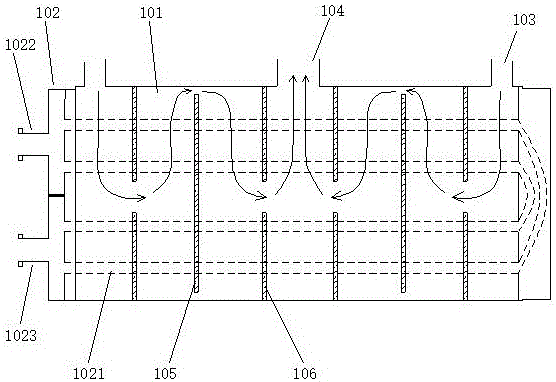

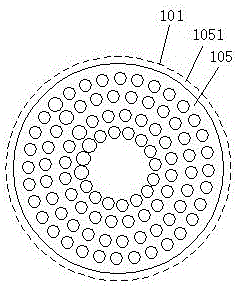

[0069] Such as Figure 6 As shown, the bearing cooling structure includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling cham...

Embodiment 2

[0077] The difference from Embodiment 1 is that: Figure 9 As shown, the bearing cooling structure includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling chamber 1, and the cooling body 2 is coaxial with the cooling chamber 1; the cooling chamber 1 contains two hot oil inlets port 11 and a cold oil outlet 12, two hot oil inlets 11 are respectively the first hot oil inlet 111 and the second hot oil inlet 112, the first hot oil inlet 111 and the second The hot oil inlet 112 is located at both ends of the cooling chamber 1, and the cold oil outlet 12 is located in the middle of the cooling chamber 1;

[0078] Such as Figure 9As shown, the cooling body 2 includes a cooling pipe 21, a water inlet flange 22, an outlet flange 23, a bottom hole flow passage partition 3 and a top hole flow passage partition 4, and the cooling pipe 21 includes a water inlet 211 and a water outlet 212 , the water inlet 211 is connected to the water inlet flange...

Embodiment 3

[0086] The difference from Embodiment 1 is that: Figure 10 As shown, the bearing cooling structure includes a cooling chamber 1 and a cooling body 2, the cooling body 2 is located in the cooling chamber 1, and the cooling body 2 is coaxial with the cooling chamber 1; the cooling chamber 1 contains a hot oil inlet A port 11 and a cold oil outlet 12, the hot oil inlet 11 and the cold oil outlet 12 are respectively located at both ends of the cooling chamber 1;

[0087] Such as Figure 10 As shown, the cooling body 2 includes a cooling pipe 21, a water inlet flange 22, an outlet flange 23, a bottom hole flow passage partition 3 and a top hole flow passage partition 4, and the cooling pipe 21 includes a water inlet 211 and a water outlet 212 , the water inlet 211 is connected to the water inlet flange 22, and the water outlet 212 is connected to the water outlet flange 23, and the water inlet flange 22 and the water outlet flange 23 are located on the side of the cooling chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com