Oil well intermittent pumping control system and method

A control system and control method technology, which is applied in pump control, earthwork drilling, wellbore/well components, etc., can solve the problems of not too much room for parameter adjustment, aggravated negative impact, and lengthened stroke, so as to reduce energy consumption, Effects of reduced loss and long communication distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

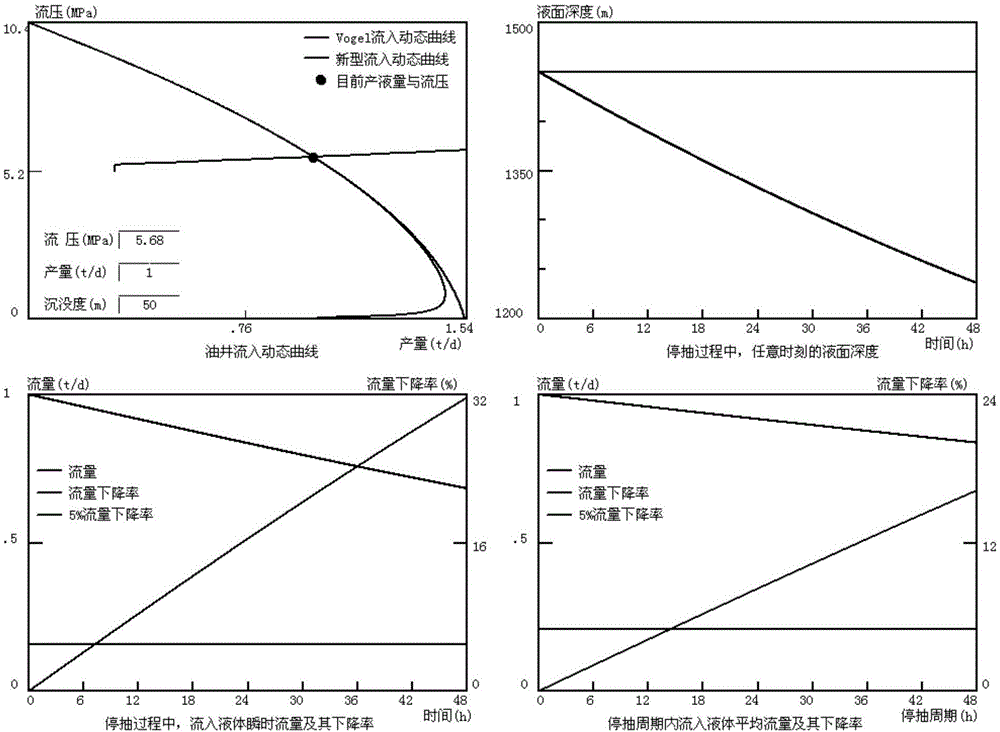

[0100] see figure 2 As shown, according to the interval pumping control simulation model, it can be calculated that the daily liquid production rate of the oil well is Q=1t / d. If the loss rate of the liquid production rate is to be less than 5%, see that the average flow rate of the inflow fluid and its drop rate during the pumping stop period are less than 14 Hours, normal pumping is greater than 8 hours.

[0101] Through simulation analysis, combined with the given allowable production decline limit, the longest pumping stop period and the corresponding pumping cycle can be determined.

[0102] The interval pumping system of oil wells with different liquid production rates is optimized based on the production decline rate not greater than 5%. The systems for different output ranges are:

[0103] When the production of the oil well is ≤1t / d, the accumulative shutdown time is 12 hours;

[0104] When the oil well production is 1t / d~1.5t / d, the accumulative pumping stop time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com