Construction method and construction device for controlling flatness of cast-in-place reinforced concrete slope surface of discharging platform

A technology of reinforced concrete and unloading platform, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficulty in guaranteeing the elevation and flatness of slope structures, and achieve good project entity effect, convenient construction and construction effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

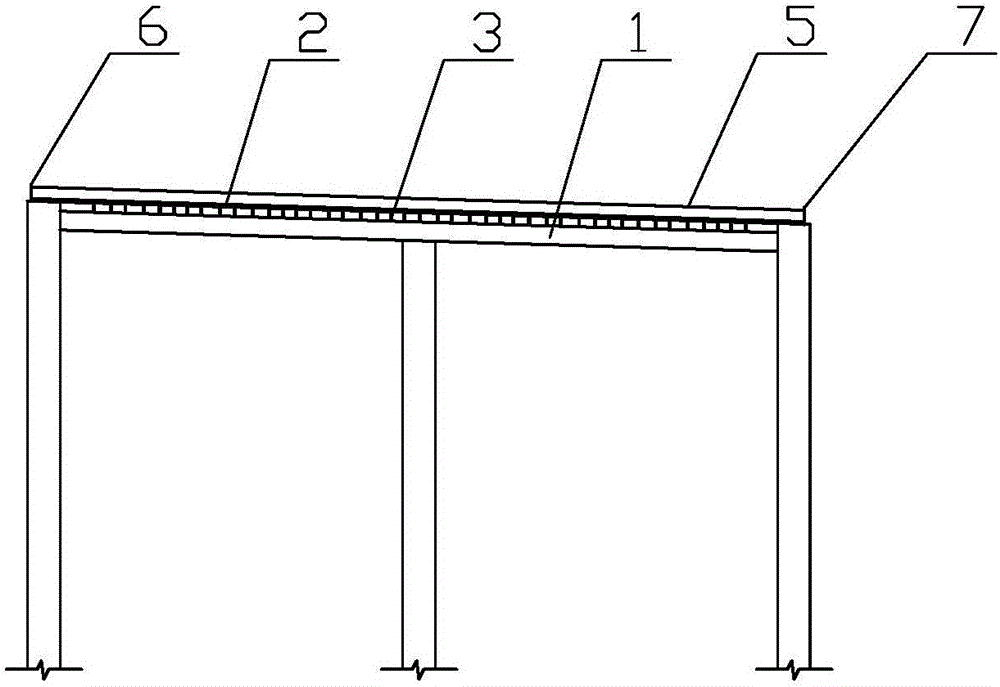

[0026] The construction technology and device of the present invention will be described in detail below in conjunction with the accompanying drawings and the specific construction process.

[0027] Such as figure 1 , figure 2 , image 3 As shown; firstly, formwork and steel bars are sub-itemly built according to the design drawings and construction scheme requirements to complete the slope structure formwork 1, and the slope surface is completed by binding beams, slabs, and steel bars. Then start from one end at the top of the slope, weld steel wires to fix support 6 (column steel bars are used, when there is no column steel bar, steel bars with a diameter of 16mm are used alone, the welding height is preferably 350mm exposed on the plate gluten, and the steel bar spacing is 300mm), at the same time, Starting from one end at the bottom of the slope, the same welded steel wires are used to fix the support 7 (column steel bars are used, and when there is no column steel bar,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com