Wall-mounted facing brick and mounting method

An installation method and technology of facing bricks, which are applied in covering/lining, construction, building structure, etc., can solve the problems of reducing construction time and the failure of sand-cement bonding facing bricks, so as to reduce construction time and processing cost. and transportation costs, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

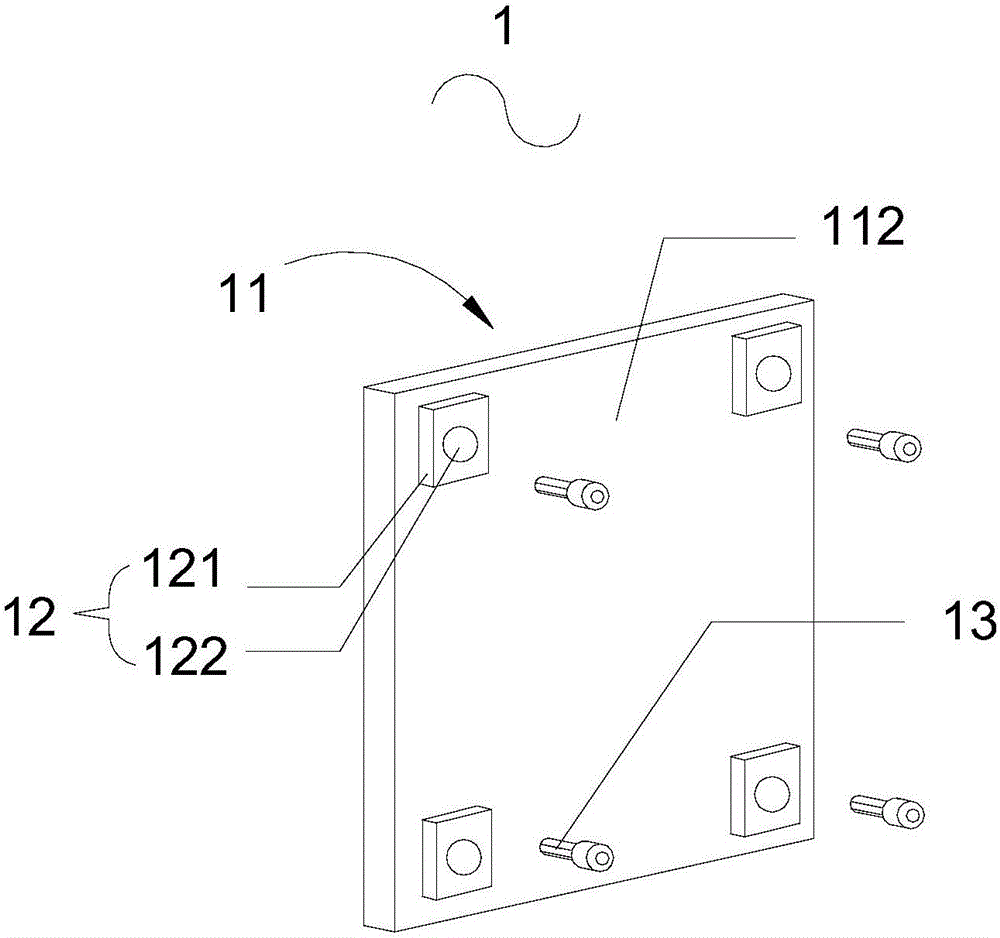

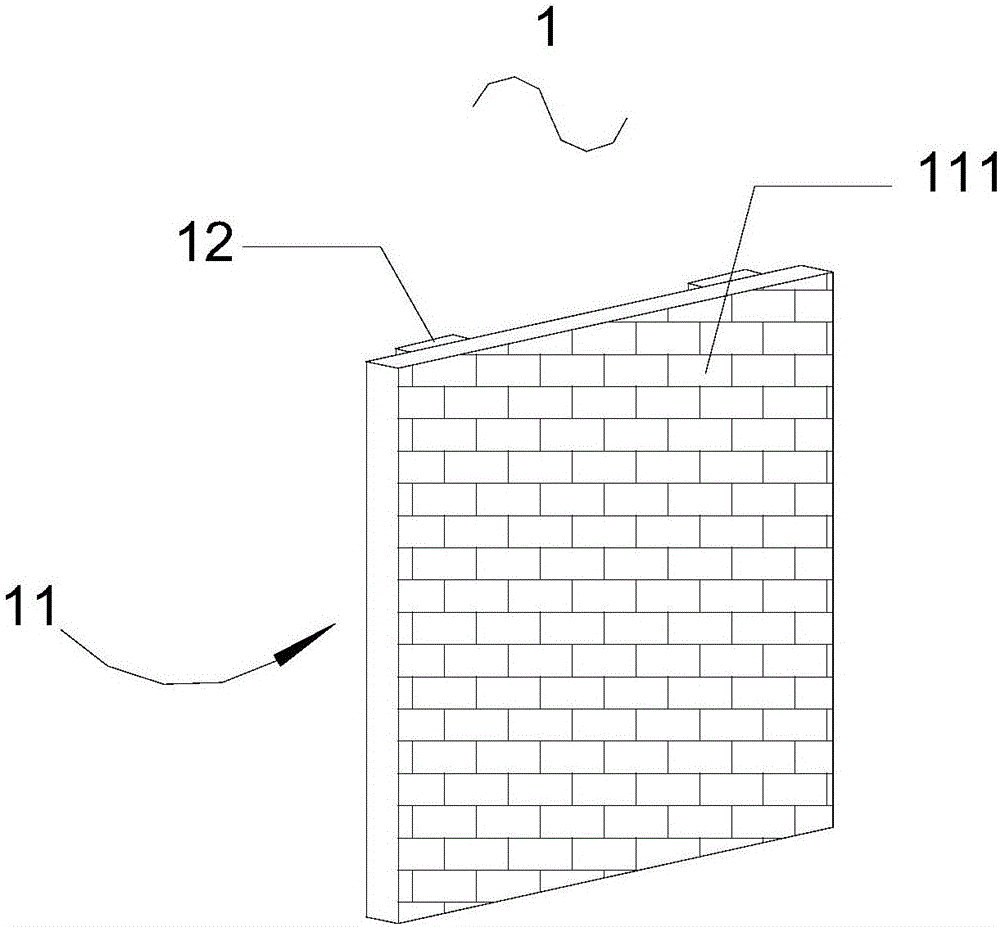

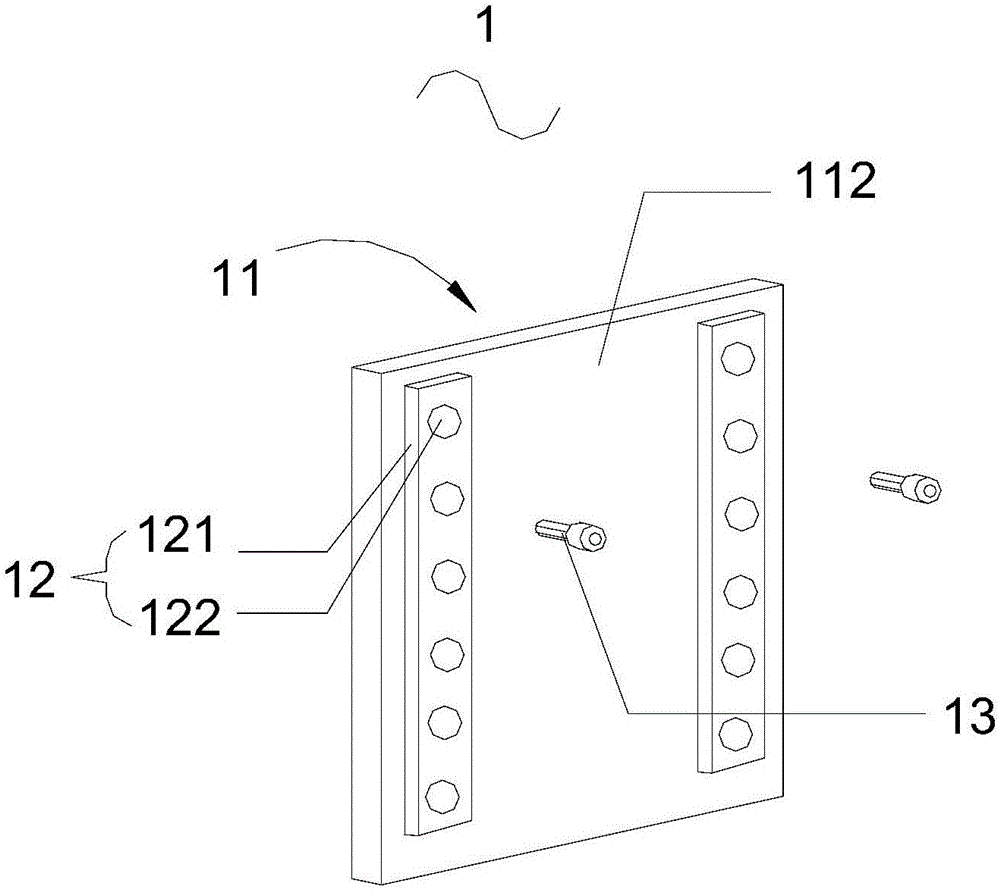

[0055] See attached figure 1 to attach image 3 , the wall-mounted decorative brick 1 provided by the present application includes a brick body 11 and an anchoring structure 12;

[0056] The brick body 11 includes a decorative surface 111 and an installation surface 112 away from the decorative surface 111;

[0057] The anchoring structure 12 is arranged on the installation surface 112;

[0058] The anchoring structure 12 includes a base 121 and an anchoring groove 122 disposed on a side of the base 121 away from the mounting surface 112 .

[0059] In the above, it needs to be understood that traditional decorative bricks are mainly divided into three types: exterior wall bricks, interior wall bricks and artistic modeling bricks in special parts. Divided from the firing materials and techniques, there are mainly ceramic mosaic tiles, ceramic floor tiles, red cylinder bricks, stone-plastic anti-skid floor tiles, porcelain floor tiles, polished tiles, glazed tiles, vitrified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com