Roof water accumulation preventing structure with tubular daylighting system of lightweight steel roof building

A light guide and water-prevention technology, which is applied in building structures, buildings, roofs, etc., can solve the problems of easy water accumulation in light guides, and achieve the effect of solving easy water accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

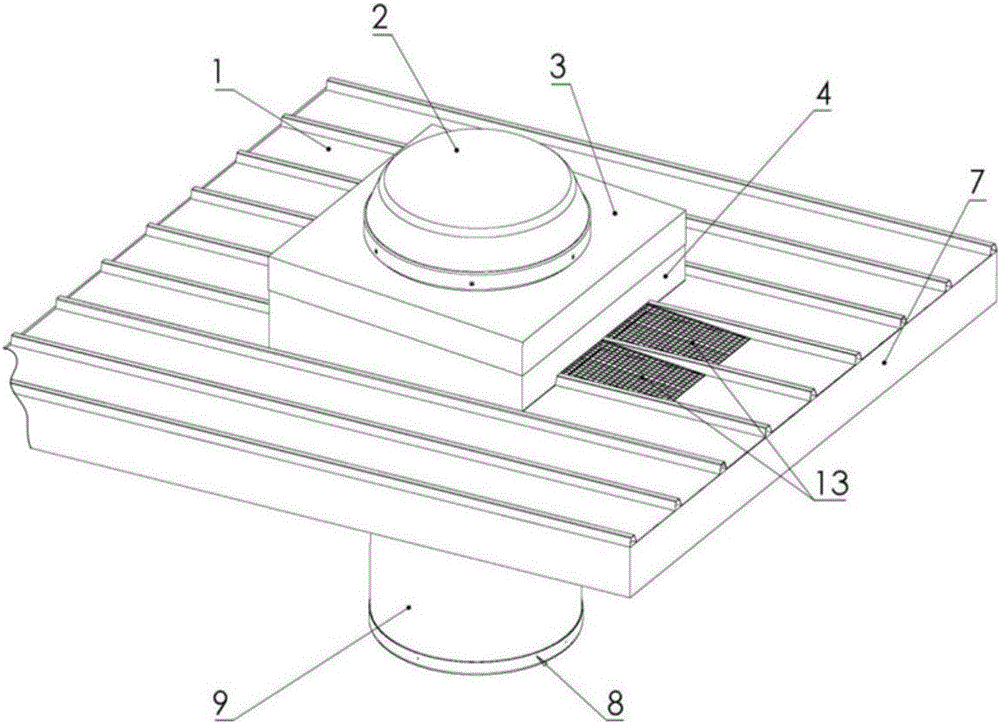

[0024] to combine figure 2 , the light steel roof construction of this embodiment installs the roof water-proof structure of the light pipe, which is installed on the light steel roof 1, and the light steel roof 1 is provided with reinforcing ribs in parallel and evenly distributed, and the light steel roof 1 is arranged along the reinforcing ribs. The direction of extension is inclined downwards.

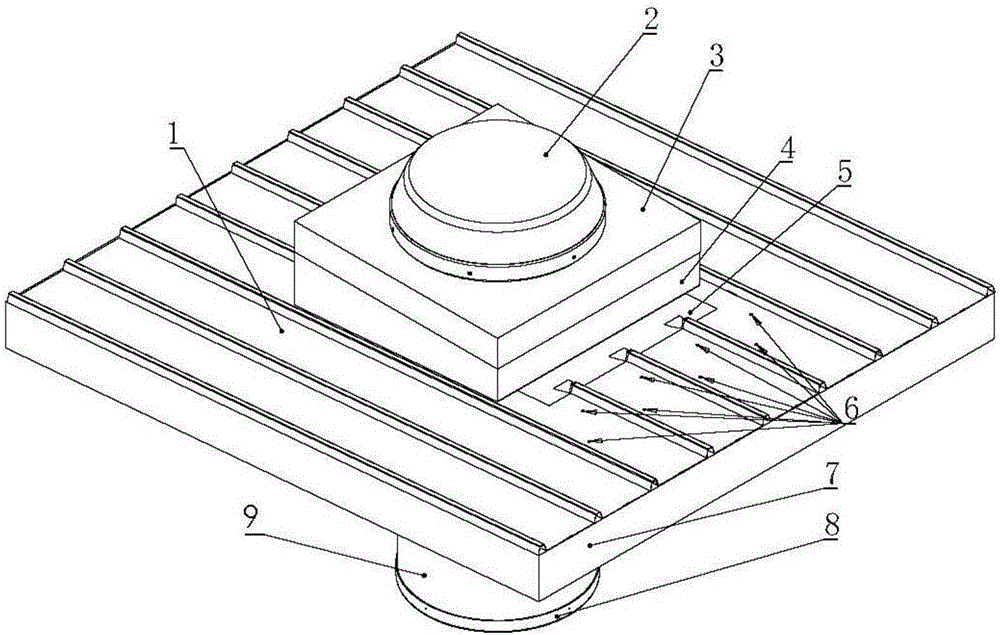

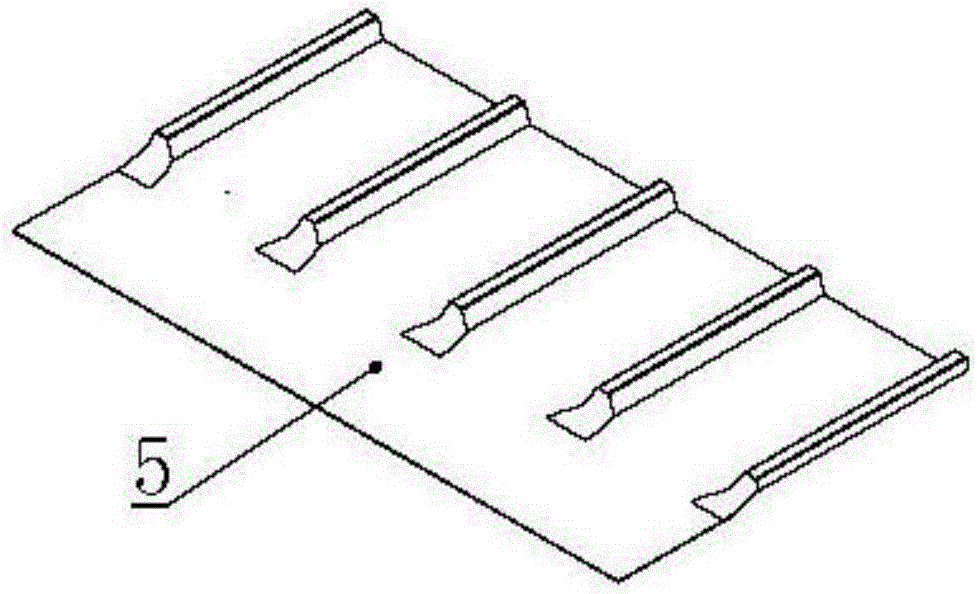

[0025] to combine Figure 2 to Figure 4 , the roof anti-water structure mainly includes a daylighting cover 2, a rain cap 3, a light guide 9, a diffuser 8, a podium 4 and a drainage sheet 5. The first end of the drainage sheet 5 is formed with accommodating grooves that match the reinforcing ribs of the light steel roof 1 to fit and fix the light steel roof 1, and the second end has a planar structure, and the light steel roof 1 corresponds to the drainage The position of the second end of the sheet is also a planar structure; the pier 4 is installed on the top outside of the li...

Embodiment 2

[0031] to combine Figure 6 The roof water-proof structure of the light steel roof building installation light guide of this embodiment is basically the same as that of the first embodiment, including a lighting cover 2, a rainproof cap 3, a light guide 9, a diffuser 8, a podium 4 and a drainage sheet 5. The plinth 4 is installed on the top outside of the light steel roof 1 , and the pier 4 and the light steel roof 1 are provided with through holes, and then the light guide 9 is installed through the light steel roof 1 .

[0032] The main difference is that the first end of the drainage sheet 5 is covered and installed on the upper side of the outer end of the light steel roof 1, and the connection between the drainage sheet 5 and the light steel roof 1 is also sealed, which can also achieve the technical effect of drainage.

[0033] to combine Figure 7, a drainage groove is formed between two adjacent reinforcing ribs on the light steel roof 1, and the rainwater flows alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com