Detachable heat insulation composite wall applied to container

A thermal insulation composite and composite wall technology, which is applied to walls, building components, buildings, etc., can solve the problems of complex disassembly and installation process, lack of protection of air barrier layer, and short service life, so as to ensure maintainability and reduce construction cost. The effect of dew phenomenon, disassembly and installation flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

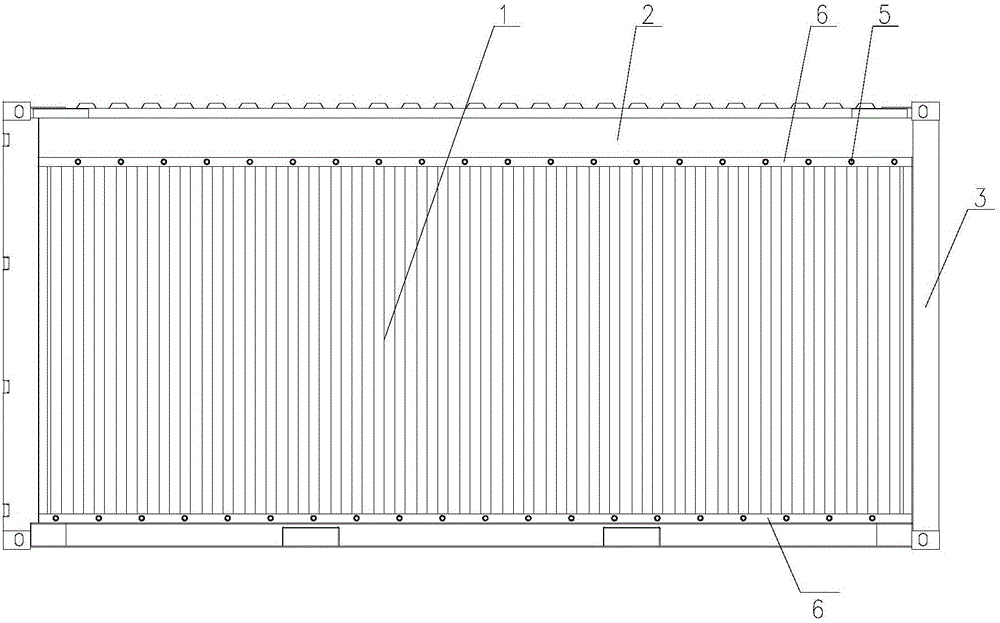

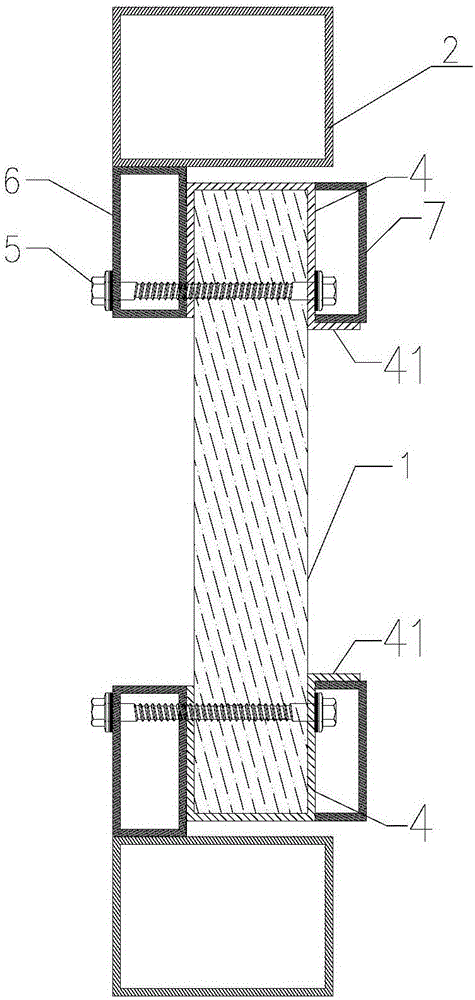

[0024] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment; this embodiment is a detachable thermal insulation composite wall applied to a container. Part 4, two-way anti-rust bolt with sealing rubber pad 5, composite wall bead 6, bolt buckle 7;

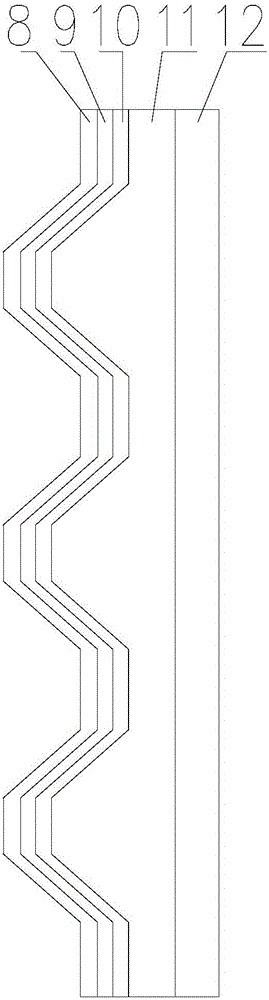

[0025] The main body 1 of the thermal insulation composite wall is composed of a single-layer color steel profiled wall panel 8, a polyethylene volute elastic cushion layer 9, a thermal insulation board 10, a porous fiberboard 11 and a decorative surface layer 12; the single layer color steel profiled wall panel 8. The polyethylene volute elastic cushion 9, thermal insulation board 10, porous fiberboard 11 and decorative surface layer 12 are arranged sequentially from outdoor to indoor;

[0026] The two horizontal steel beams 2 and the two vertical steel beams 3 encircle to form a rectangular frame, the thermal insulation composite wall body 1 is arranged in the rectangular frame, the main body of...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that one side of the composite wall bead 6 is connected to the outer surface of the channel steel vertical arm of the wall connector 4 that is not provided with strip metal. welding. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the composite wall bead 6 and the horizontal steel beam 2 are fixedly connected by welding. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com