Combined hydraulic rectification device of pump station water inlet pool at ultralow water level

A technology of rectification device and water inlet pool, which is applied in water supply devices, pump stations, buildings, etc., can solve the problems of poor flow state of water inlet pool and poor effect of pump stations, etc., to eliminate bottom vortex and backflow, eliminate water flow turbulence, prevent The effect of sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

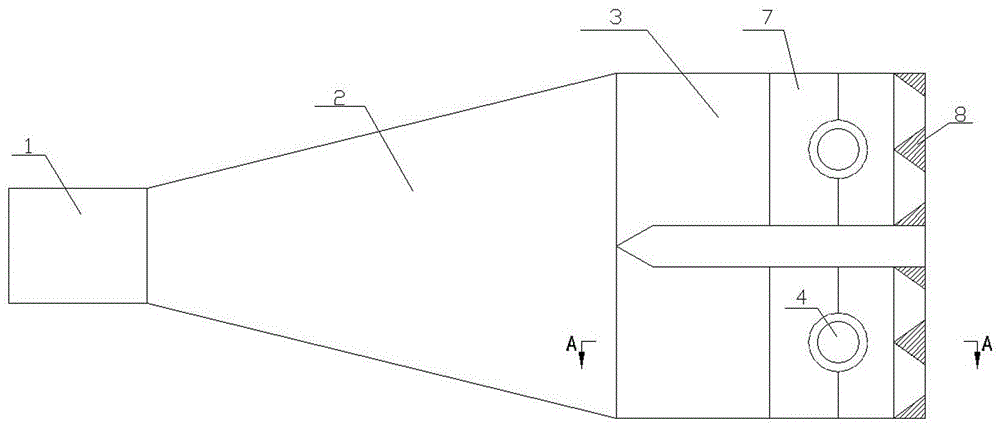

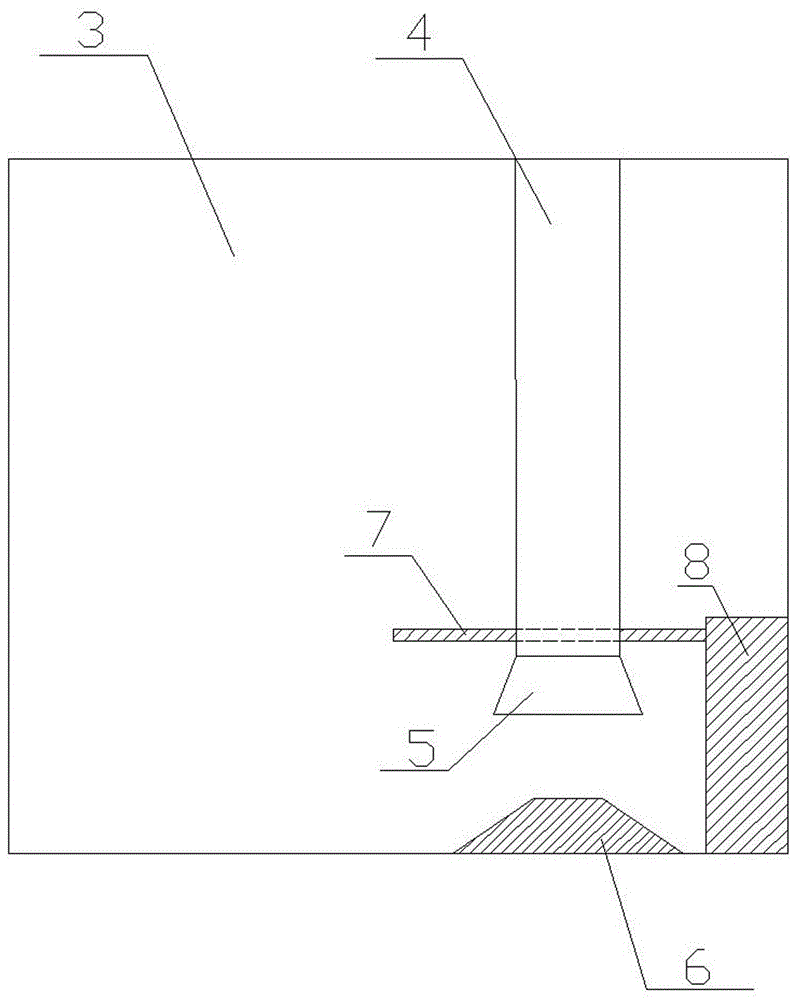

[0032] Embodiment 1: In this embodiment, if Figure 1-2As shown, a combined hydraulic rectification device under the ultra-low water level of the water inlet pool of the pumping station, including the water diversion channel 1, the forebay 2 and the water inlet pool 3, and also includes the water inlet pipe 4 connected to the water pump, the water inlet trumpet pipe 5, and the diversion Platform 6, underwater vortex elimination cover plate 7 and "W" type diversion pier 8, the water inlet pipe 4 extends downward into the rear end of the water inlet pool, and the inlet end of the water inlet pipe 4 is connected to the outlet end of the water inlet horn pipe 5 , the inlet diameter of the water inlet horn tube 5 is greater than the outlet diameter; the deflector 6 is arranged on the bottom plate of the water inlet pool 3, located directly below the water inlet horn tube 5, and the axis of the guide table 6 and the water inlet horn tube 5 Coincident; the circumferential surface of ...

Embodiment 2

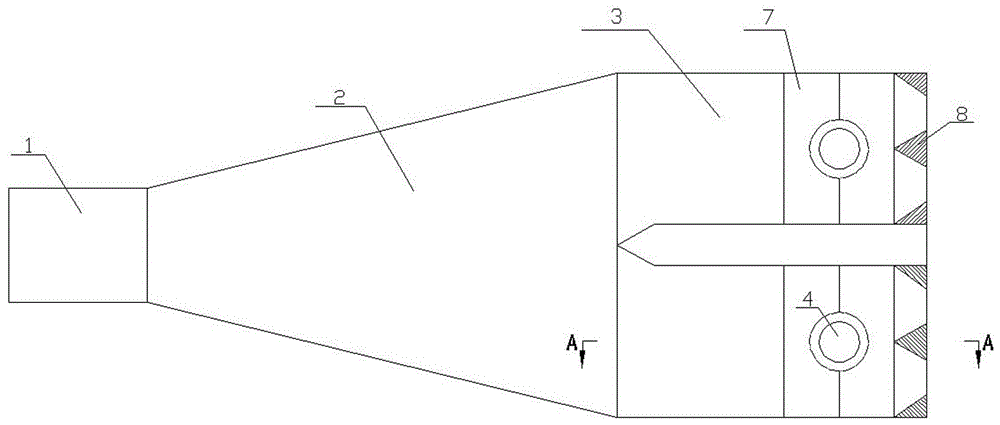

[0038] Embodiment two: if Figure 3-4 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the flow guide table 6 is divided into upper and lower parts, and the circumferential surface of the upper part of the flow guide table 6 is formed by a circular arc around the flow guide table 6 A smooth curved surface formed by the axis of the flow guide table 6, the circumferential surface of the lower part of the flow guide table 6 is a smooth curved surface formed around the axis of the flow guide table 6 by a segment of oblique line, the circumferential surface of the upper part of the flow guide table 6 and the lower part of the flow guide table 6 Smooth transitions on the circumference.

[0039] The diversion middle pier of the "W"-shaped diversion pier 8 is an equilateral triangular prism.

[0040] The height of the upper part of the flow guide table 6 is 2 / 3 of the height of the flow guide table 6 , and the height of the lower part of the flo...

Embodiment 3

[0041] Embodiment 3: This embodiment is basically the same as Embodiment 1. The difference is that the height of the diversion platform 6 is 1 / 3 of the height of the inlet of the water inlet trumpet tube 5 and the height of the bottom plate of the water inlet pool 3 . The distance between the leading edge and the trailing edge of the vortex cover plate 7 is 1.2 times and 1.0 times of the inlet diameter of the water inlet horn pipe 5 respectively from the center of the water inlet horn pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com