Energy dissipator for architectural drainage system

A technology of building drainage and energy dissipator, which is applied in construction, water supply equipment, indoor sanitary pipeline installations, etc., can solve the problems of insufficient strength, loud drainage noise, and occupying building space, so as to avoid negative pressure suction and reduce Drainage noise, effect of increasing drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

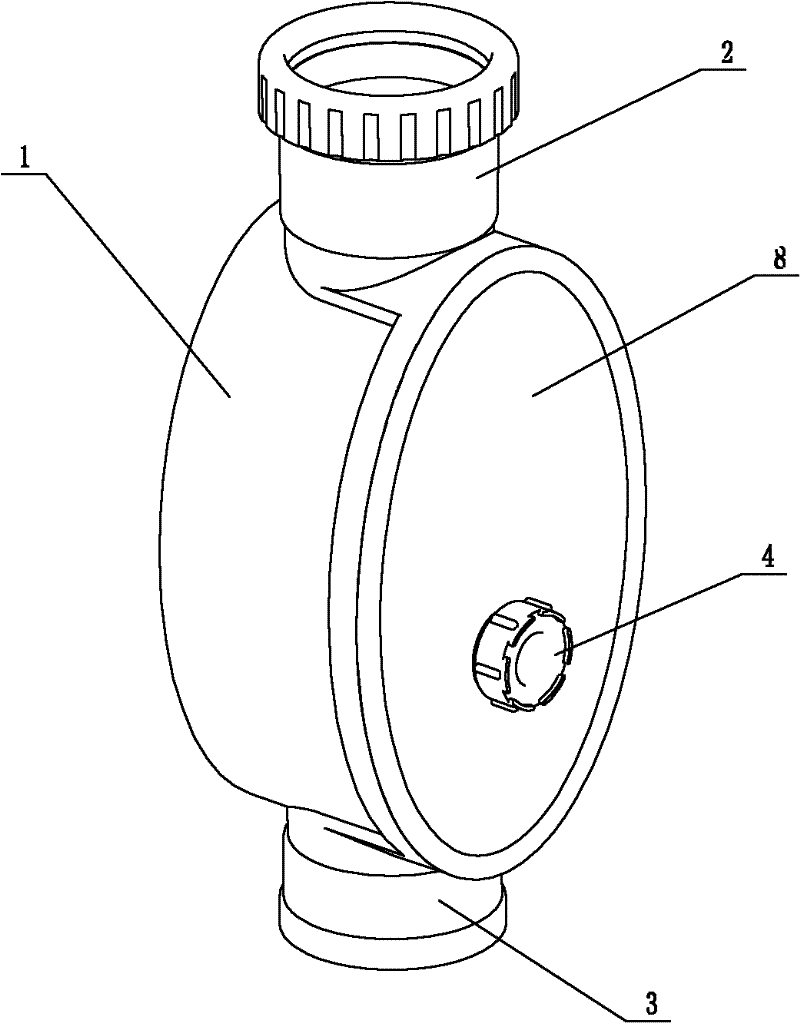

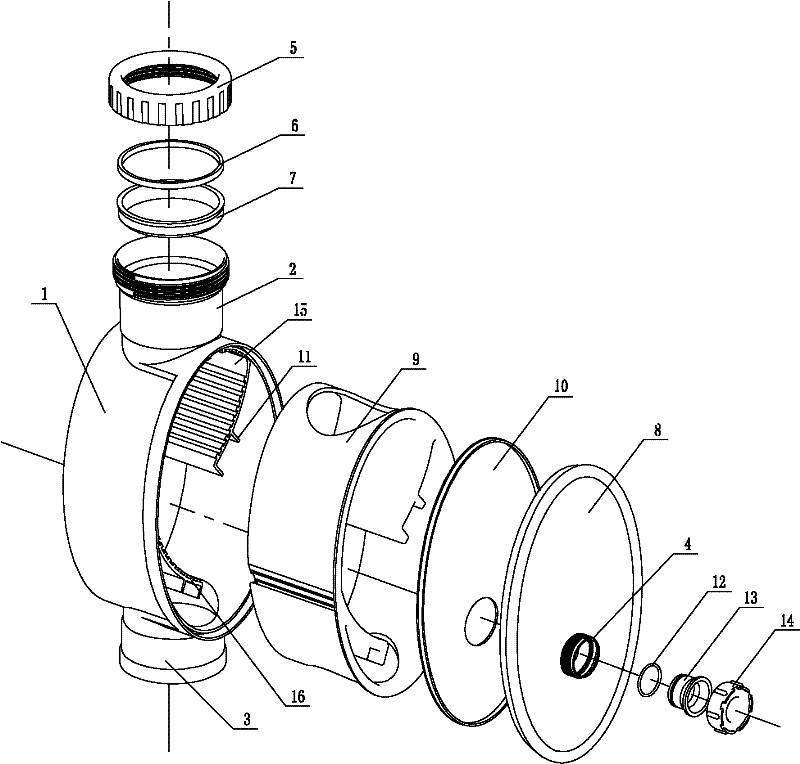

[0021] As shown in the figure, the main body 1 of the energy dissipator has an elliptical shape, and the inner cavity of the main body 1 has two gradually changing arc-shaped water flow baffles 15 and 16 arranged up and down. The main body soft liner 9 applied on the main body inner wall and the water flow baffle has a through hole on its upper and lower parts, and the inner cavity of the main body soft liner communicates with the riser inlet and the outlet respectively. The inner wall of the cover plate 8 is coated with a soft inner lining 10 of the cover plate, and the main body and the cover plate 8 are glued together. An inspection port 4 is provided on the cover plate 8, and the inspection port 4 is connected with a cover 14, and a plug 13 is installed between the inspection port 4 and the cover 14, and the plug 13 is covered with an O-ring 12. The arcs of the water flow baffles 15 and 16 are downward, the width of the water flow baffles is 1 / 3-2 / 3 of the main body width,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com