Novel water permeable block brick and preparation method thereof

A technology of water permeability and building blocks, which is applied to other household appliances, roads, pavement details, etc., can solve the problems that affect the service life and quality of building blocks, poor water permeability, etc., and achieve the ability of improving oxidation resistance and UV protection, and low cost , the effect of less clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

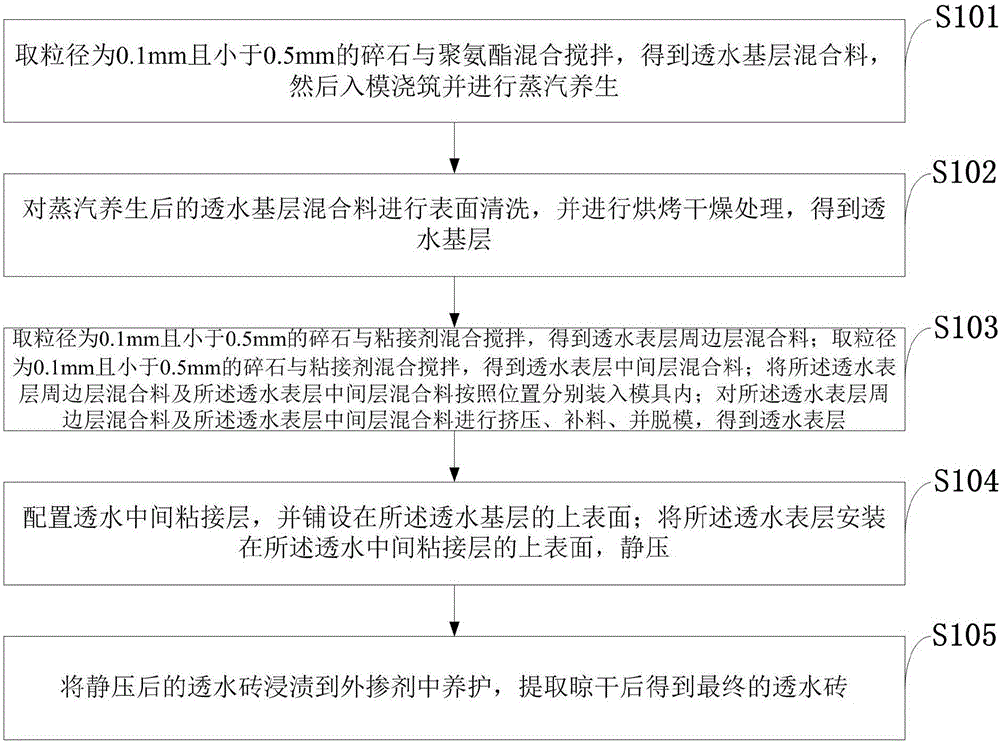

[0023] Such as figure 1 As shown, the preparation method of the novel water-permeable building block provided by the embodiment of the present invention includes the following steps:

[0024] S101: Mix and stir gravel with a particle size of 0.1mm and less than 0.5mm with polyurethane to obtain a water-permeable base layer mixture, which is then poured into a mold and steam-cured;

[0025] S102: Perform surface cleaning on the water-permeable base layer mixture after steam curing, and perform baking and drying treatment to obtain the water-permeable base layer;

[0026] S103: Take crushed stones with a particle size of 0.1 mm and less than 0.5 mm and mix and stir with the adhesive to obtain a mixture for the permeable surface layer; take crushed stones with a particle size of 0.1 mm and less than 0.5 mm and mix and stir with the adhesive. Obtain the water-permeable surface layer middle layer mixture; put the water-permeable surface layer peripheral layer mixture material and the wat...

Embodiment 1

[0033] The novel water-permeable building block provided by the embodiment of the present invention includes a water-permeable surface layer and a water-permeable base layer, and the water-permeable surface layer and the water-permeable base layer are tightly integrated into a whole; the water-permeable surface layer and the water-permeable base layer respectively contain aggregate and polyurethane bonding aggregate; the bone The material is crushed stone; the aggregate particle size in the permeable surface layer is 0.2 mm.

[0034] The mass ratio of the binder to the aggregate in the water-permeable surface layer is 30:90.

[0035] The hydrophilic binder in the water-permeable surface layer accounts for 70% of the binder in the water-permeable surface layer.

[0036] The preparation method of the novel water-permeable building block provided by the embodiment of the present invention includes the following steps:

[0037] Step 1: Take crushed stone with a particle size of 0.2mm and ...

Embodiment 2

[0043] The novel water-permeable building block provided by the embodiment of the present invention includes a water-permeable surface layer and a water-permeable base layer, and the water-permeable surface layer and the water-permeable base layer are tightly integrated into a whole; the water-permeable surface layer and the water-permeable base layer respectively contain aggregate and polyurethane bonding aggregate; the bone The material is crushed stone; the aggregate particle size in the permeable surface layer is 0.4mm.

[0044] The mass ratio of the binder to the aggregate in the water-permeable surface layer is 35:90.

[0045] The hydrophilic binder in the water-permeable surface layer accounts for 70% of the binder in the water-permeable surface layer.

[0046] The preparation method of the novel water-permeable building block provided by the embodiment of the present invention includes the following steps:

[0047] Step 1: Take crushed stone with a particle size of 0.4mm and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com