Microcapsule for preparing temperature-adjusting textile product, preparation method and application thereof, as well as temperature-adjusting textile product

A technology of microcapsules and textiles, applied in the field of textile fabric production, can solve the problems of poor fastness between coating and substrate, poor fastness between phase change materials and textiles, and the combination ability of microcapsules and yarns has not been considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

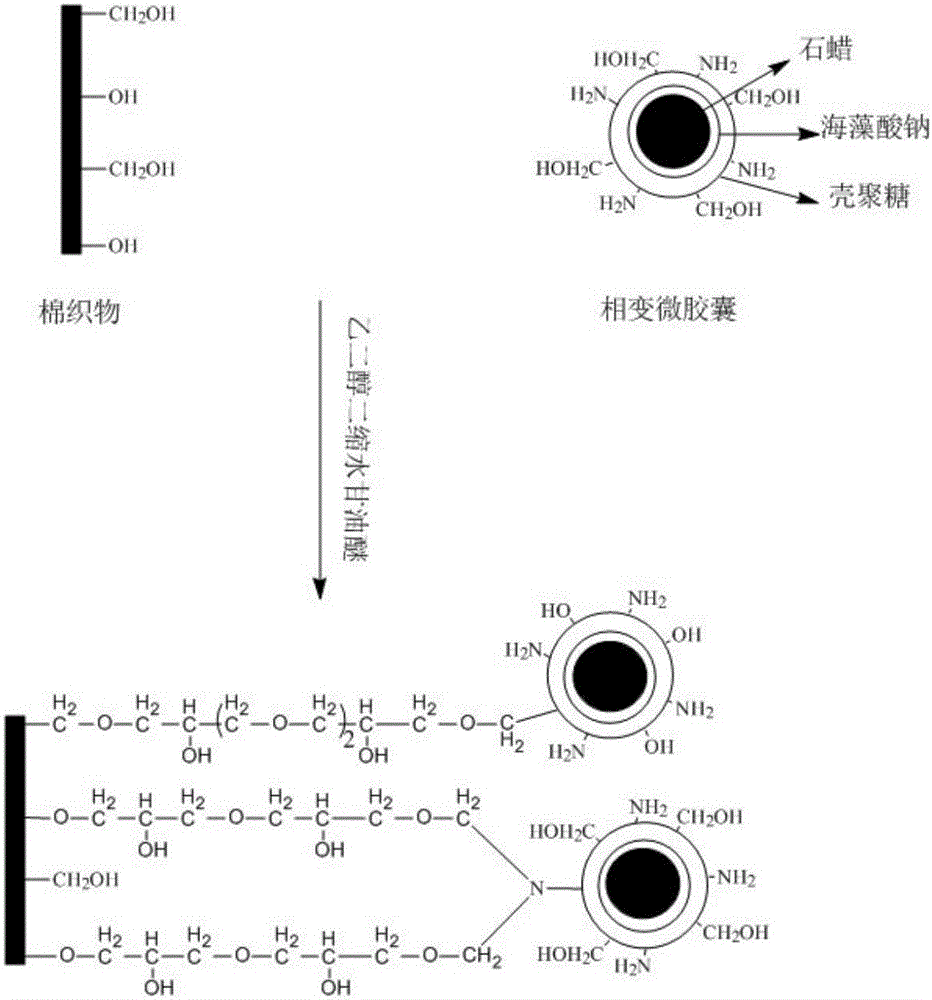

[0026] The invention provides a method for preparing microcapsules for preparing temperature-regulating textiles, comprising the following steps:

[0027] (1) mixing the mixed solution comprising sodium alginate and calcium carbonate with paraffin and water-oil composite emulsifier, and carrying out an emulsification reaction to obtain an oil-in-water emulsion;

[0028] (2) mixing the oil-in-water emulsion obtained in the step (1) with sherwood oil and an acidic solvent, and performing a curing reaction to obtain primary microcapsules;

[0029] (3) The primary microcapsules obtained in the step (2) are condensed with chitosan acidic solution to obtain microcapsules for temperature-regulating textiles.

[0030] The invention mixes the mixed solution including sodium alginate and calcium carbonate with paraffin wax and water-oil compound emulsifier. In the present invention, the mass ratio of sodium alginate, calcium carbonate and water in the mixed solution is preferably (1-3)...

Embodiment 1

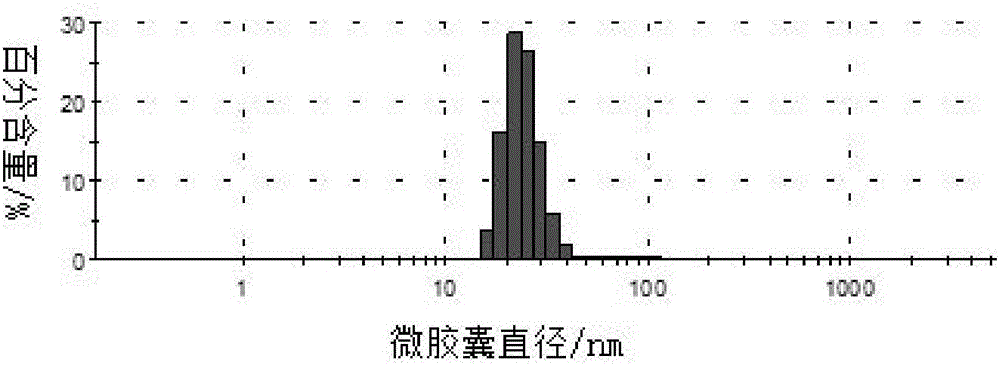

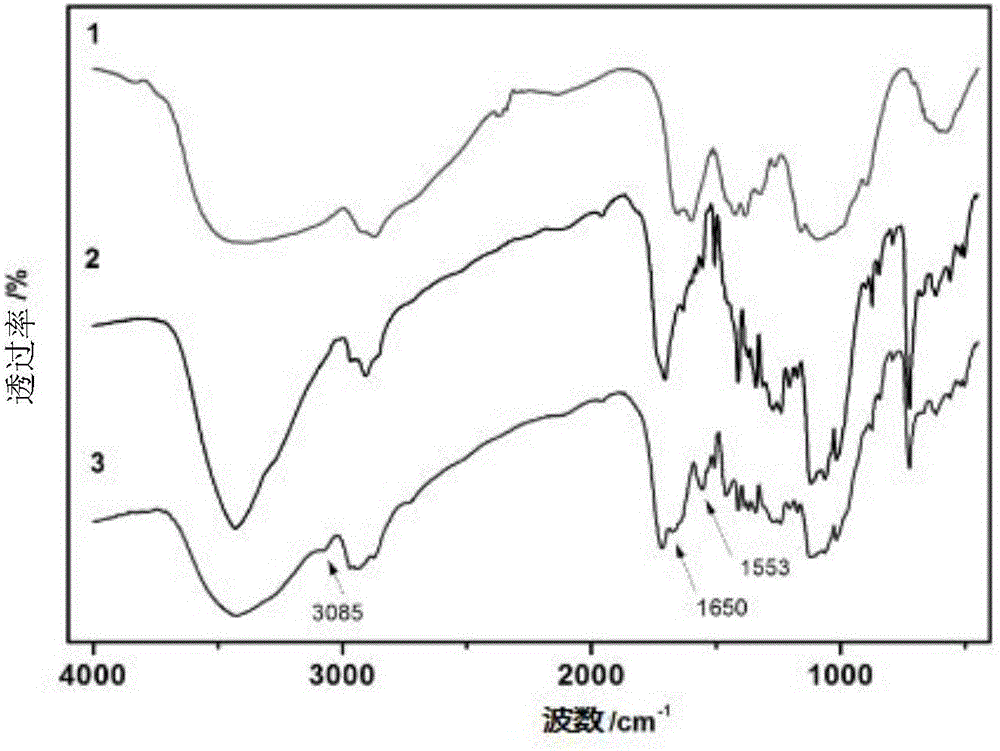

[0069] Preparation of microcapsules: in parts by mass, dissolve 1.0 part of sodium alginate and 0.5 part of calcium carbonate with 80 parts of water at 45°C, add 1.0 part of sliced paraffin and 6 parts of water-oil compound emulsifier (water-oil compound emulsifier After being emulsified for 30min with a mass ratio of Tween-80 and Span-80) of 6:4, an oil-in-water emulsion was obtained; the oil-in-water emulsion was dispersed in 80 parts of petroleum ether and 0.25 part of acetic acid mixed solution, Stir at a speed of 2000rpm for 10min, then add 80 parts of 0.05mol / L calcium chloride aqueous solution, and also stir at a speed of 2000rpm for 10min to obtain primary microcapsules coated with paraffin wax sliced by sodium alginate; place the prepared primary microcapsules in Mass concentration is 0.2% in the chitosan acetic acid solution, wherein the mass parts of chitosan is 2 parts, soak 0.5h, adopt xylene to wash 3 times, absolute ethanol wash 3 times and the mode of distil...

Embodiment 2

[0073] Preparation of microcapsules: in parts by mass, dissolve 1.5 parts of sodium alginate and 0.75 parts of calcium carbonate with 85 parts of water at 45°C, add 1.5 parts of sliced paraffin and 8 parts of water-oil compound emulsifier (water-oil compound emulsifier Carry out emulsification for 35min after mass ratio is Tween-80 and Span-80) of 6:4, obtain oil-in-water type emulsion; Oil-in-water type emulsion is dispersed in 85 parts of sherwood oil and 0.5 part of acetic acid mixed solution, Stir at a speed of 2000rpm for 10min, then add 85 parts of 0.05mol / L calcium chloride aqueous solution, and also stir at a speed of 2000rpm for 10min to obtain primary microcapsules wrapped with paraffin wax in sodium alginate; place the prepared primary microcapsules in Mass concentration is 0.4% chitosan acetic acid solution, soak 1h, and wherein the relative mass part of chitosan is 2.5 parts, successively adopt the mode that xylene washes 3 times, anhydrous ethanol washes 3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com