Cellulose-based flexible heat storage composite material and preparation method thereof

A composite material and base flexible technology, applied in the field of heat storage composite material preparation, can solve problems such as hindering application and poor degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This implementation provides a method for preparing a heat storage composite material, the steps are as follows:

[0038] (1): 16g wood pulp-carboxylated cellulose nano-suspension (CNF) (mass concentration is 1%) and 2g F127 and 2g deionized water are mechanically stirred until fully dissolving to obtain the water phase, and 40g octadecane is added dropwise Drop into the above water phase, and mix well to obtain an oil-in-water high internal phase emulsion;

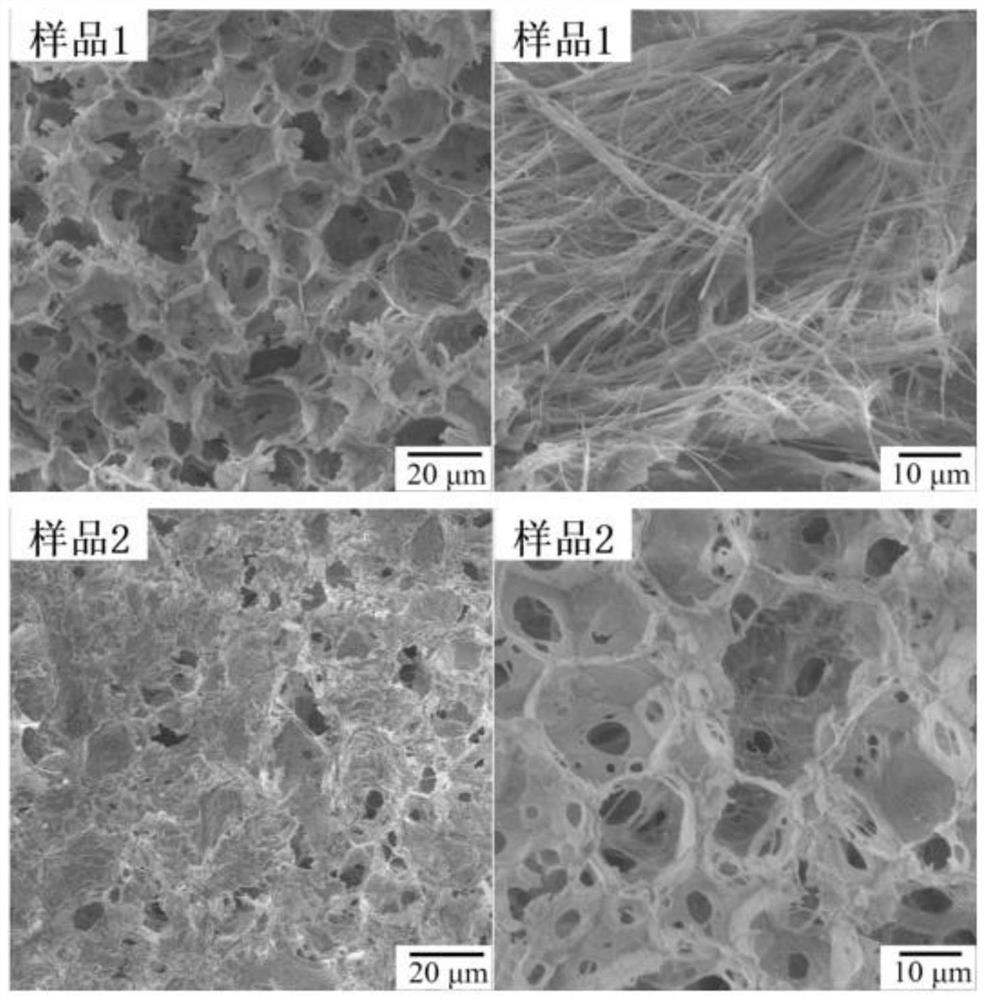

[0039](2): Add 1.0 g of hexamethylene isocyanate as a cross-linking agent and 0.02 g of dibutyltin dilaurate as a catalyst into the oil-in-water type high internal phase emulsion, mix quickly and evenly, divide the sample into two, and one part is passed through Sample 1 was obtained after heating and drying for 24 hours, and sample 2 was obtained after another part was freeze-dried for 24 hours. The heating temperature was 100°C, and the freezing temperature was -30°C.

Embodiment 2

[0041] This implementation provides a method for preparing a heat storage composite material, the steps are as follows:

[0042] (1): 16g wood pulp-carboxylated cellulose nano-suspension (CNF) (mass concentration is 1%) and 2g sorbitan monooleate and 2g deionized water are mechanically stirred until completely dissolving to obtain the water phase, and 40g of octadecane was dropped into the above water phase drop by drop, and after mixing evenly, an oil-in-water type high internal phase emulsion was obtained;

[0043] (2): Add 1.0 g of hexamethylene isocyanate as a cross-linking agent and 0.02 g of dibutyltin dilaurate as a catalyst into the oil-in-water type high internal phase emulsion, mix quickly and evenly, divide the sample into two, and one part is passed through Sample 1 was obtained after heating and drying for 24 hours, and sample 2 was obtained after another part was freeze-dried for 24 hours. The heating temperature was 100°C, and the freezing temperature was -40°C....

Embodiment 3

[0045] This implementation provides a method for preparing a heat storage composite material, the steps are as follows:

[0046] (1): 10g cotton-sulfonated cellulose suspension (0.5% mass concentration) and 1g F127 and 1g deionized water were mechanically stirred until completely dissolved to obtain the water phase, and 40g octadecane was dropped dropwise into the above water phase After mixing evenly, an oil-in-water high internal phase emulsion is obtained;

[0047] (2): Add 1.0 g of hexamethylene isocyanate as a cross-linking agent and 0.02 g of dibutyltin dilaurate as a catalyst into the oil-in-water type high internal phase emulsion, mix quickly and evenly, divide the sample into two, and one part is passed through Sample 1 was obtained after heating and drying for 24 hours, and sample 2 was obtained after another part was freeze-dried for 24 hours. The heating temperature was 90°C, and the freezing temperature was -30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com