Preparation method for compound metal fiber

A metal composite and metal fiber technology, applied in the field of materials, to shorten the processing time and avoid uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

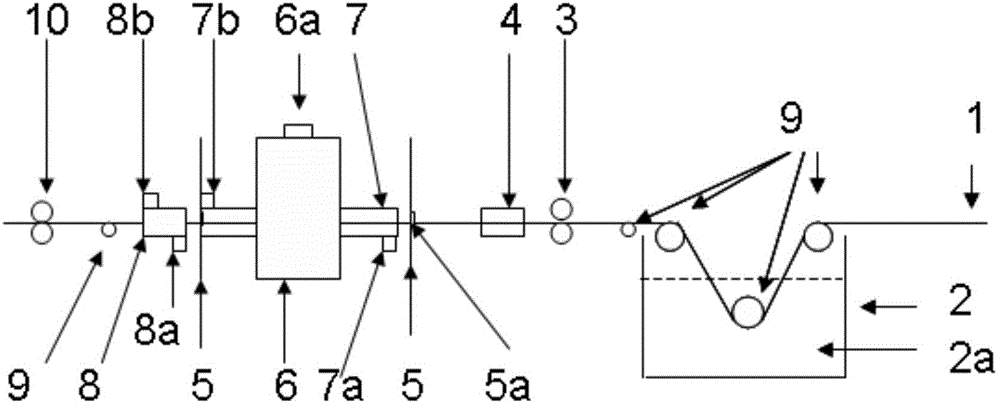

Method used

Image

Examples

Embodiment 1

[0026] First, graphene oxide powder and reduced graphene oxide powder are prepared. 30 grams of graphite mixed with 15 grams of sodium nitrate and 750 milliliters of concentrated sulfuric acid. The mixture was cooled to 0°C in an ice bath, and after stirring for 2 h, 90 g of potassium permanganate was slowly added, keeping the temperature of the mixture below 5°C during the mixing process. The mixture was stirred for another hour and allowed to warm to room temperature by removing the ice bath. Add 1 liter of distilled water to the mixture and increase the temperature in the oil bath to 90°C. Another 300 ml of water were added and stirred for another hour and a half. The color of the mixture turned brown. The mixture was then treated and diluted with 30% hydrogen peroxide in 300 ml and 30 liters of hot water. The mixture was further washed with excess water until the pH of the filtrate was almost neutral to obtain graphene oxide. Then freeze-dry the graphene oxide to obta...

Embodiment 2

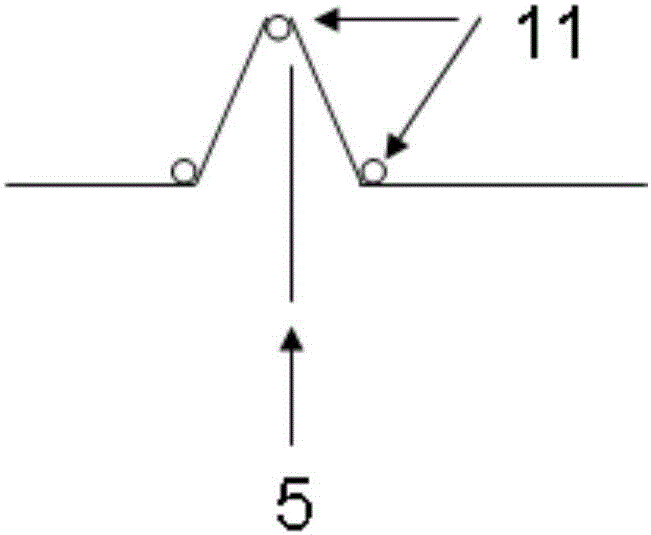

[0029] First obtain an aluminum wire with a diameter of 1 mm, then pass the aluminum wire through a 30 cm long 10 mg / ml graphene oxide aqueous solution at a speed of 0.1 m / s, and obtain a composite aluminum coated with a graphene oxide layer after drying Wire. The composite aluminum wire was heated under the protection of a reducing atmosphere with a ratio of nitrogen and hydrogen of 55:1 at a speed of 0.1 m / s at 200 degrees Celsius for about 1 second through a microwave oven with a power of 1000 W and a diameter of 10 cm in a heating zone, and then again Enter the room temperature area for cooling, and then the composite aluminum wire is extruded through an extrusion roller with a line pressure of 1000 N / cm, and the above microwave heating-cooling-extrusion process is repeated 20 times. Obtain a graphene layer with a carbon content greater than 90% and an electrical conductivity greater than 5000Sm -1 Composite aluminum wires coated with graphene layers. The composite alumi...

Embodiment 3

[0031] Edge carboxylated graphene flakes are first prepared. 5 grams of graphite and 100 grams of dry ice were added to a stainless steel capsule containing 1000 grams of 5 mm diameter stainless steel spheres. The container was sealed and fixed in a planetary ball mill (F-P4000), and stirred at a speed of 500 rpm (rotation per minute) for 48 hours. The internal pressure is then slowly released through a gas outlet. At the end of the ball milling, the lid of the container is opened in the air, and the moisture in the air triggers the carboxylate to undergo a violent hydration reaction to generate carboxylic acid and emit light. The obtained product was subjected to Soxhlet extraction with 1M hydrochloric acid solution to fully acidify the carboxylate and remove possible metal impurities. Finally, freeze-dry at minus 120 degrees Celsius for 48 hours in a vacuum environment of 0.05 mm Hg to obtain a dark black powder of edge carboxylated graphene nanosheets. Edge carboxylated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com