High-strength high dampness and heat sea atmospheric environment resistant weathering resistant steel and preparing method

A marine atmosphere, high-strength technology, applied in the field of weathering steel, can solve problems such as applicability doubts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

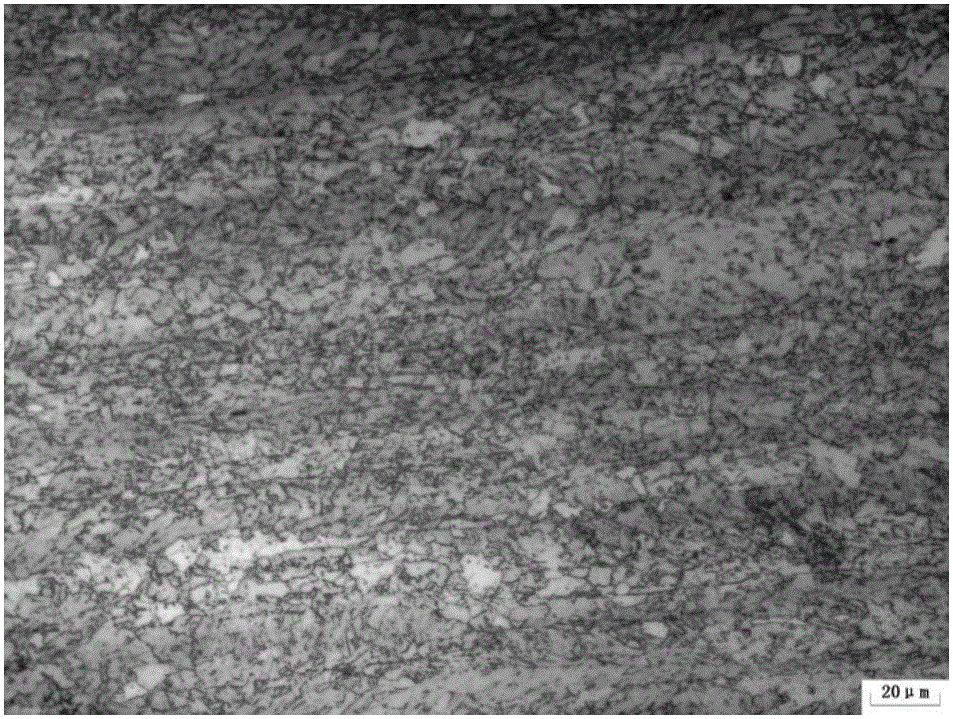

[0034] Embodiment 1 Contains Sn, Sn+Sb weathering steel's high-humidity and heat-resistant marine atmospheric corrosion

[0035] Sn and Sb elements are added to the traditional weathering steel Q450NQR1, and smelted in a 25kg vacuum induction furnace. After forging, the steel ingot is cut into 120mm×120mm×30mm squares. The rolling process is as follows: the temperature is raised to 1200°C with the furnace, and rolling is carried out after holding the heat for 1 hour. After multiple passes of rolling, a steel plate with a thickness of 6mm is obtained. The chemical composition of the test steel is shown in Table 2.

[0036] Chemical composition (wt%) of table 2 test steel

[0037]

[0038] According to the periodic infiltration corrosion test method of weathering steel for railways (TB / T2375-93) and the corrosion test method of steel bars in a chloride ion environment (YB / T4367-2014), the test parameters are set as follows: the wetting solution is 2% wtNaCl solution by mass ...

Embodiment 2

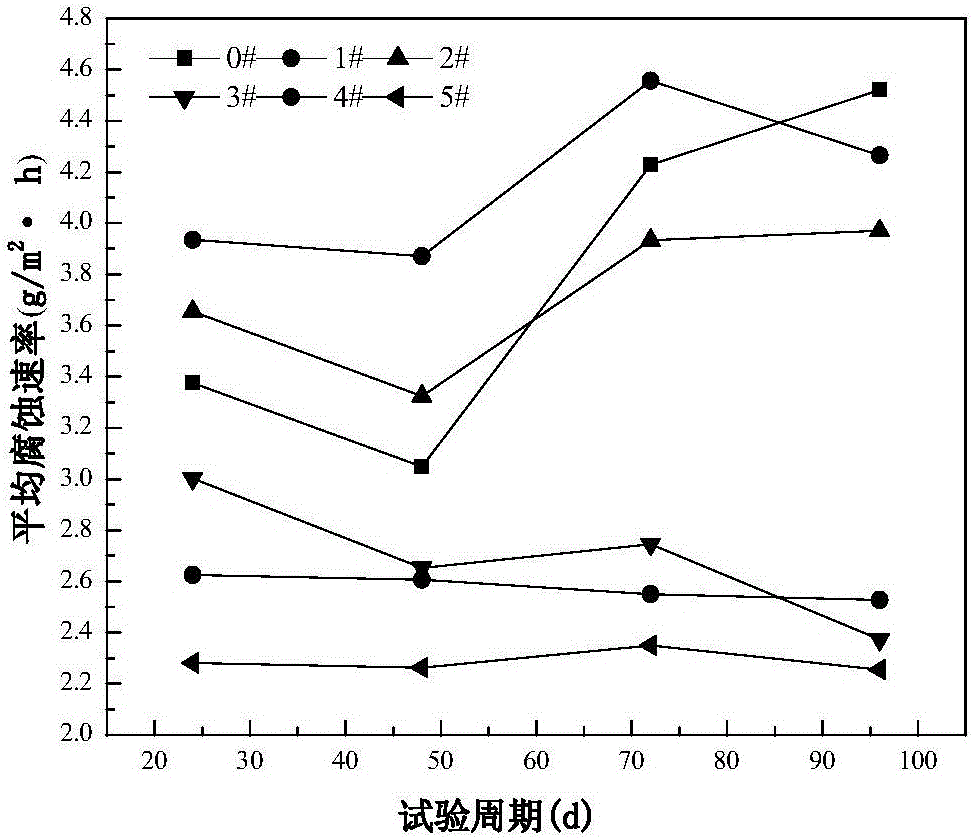

[0041] Example 2 Effects of Different Ni Contents on the Corrosion Resistance of Weathering Steels to High Humidity and Heat, Marine Atmosphere

[0042] Ni is one of the most effective corrosion-resistant elements, but due to the high cost of Ni, it is of great significance to select an appropriate Ni content to obtain weathering steel with good comprehensive performance and reasonable cost. On the basis of the composition of the Q450NQR1 weathering steel in Example 1 above, only the Ni content was changed to obtain weathering steels with different Ni contents. Then 5 kinds of Ni-containing weathering steels (respectively numbered 1#~5#) with Ni content in the range of 1%~5% were smelted in a 25kg vacuum induction furnace. The corrosion test method used is the same as in Example 1. Aiming at the effect of Ni on the corrosion resistance of weathering steel in high humidity and heat, the actual exposure test in the Xisha area of the South China Sea was carried out, and the ex...

Embodiment 3

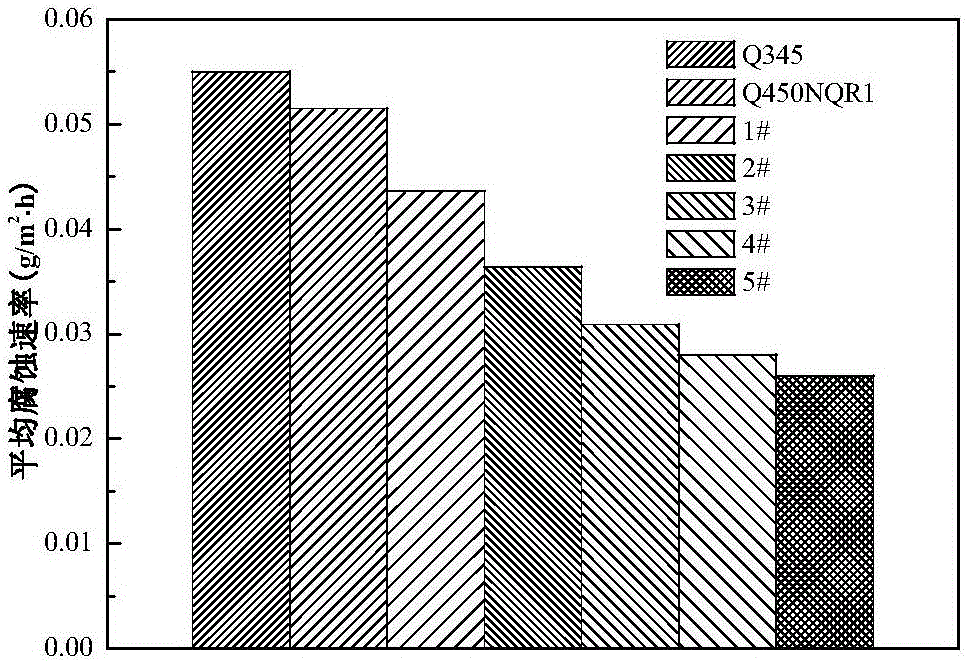

[0043] Example 3 Effect of Mo on weathering steel corrosion resistance to high humidity and heat in marine atmosphere

[0044] The influence of Mo element on the corrosion performance of weathering steel in high-humidity marine atmosphere was investigated. The laboratory 25kg vacuum induction furnace smelted Mo-containing weathering steel (1#) and Mo-free weathering steel (0#). Table 4 is the test steel chemical composition. The corrosion test method adopted is the same as in Example 1. Figure 4 It is a bar graph of the corrosion rate of the test steel. It can be seen that by adding 0.34% Mo element, the corrosion resistance of the test steel can be increased by about 10% in the high-humidity marine atmosphere environment.

[0045] Table 4 Chemical composition of Mo-containing and Mo-free test steels

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com