Pretreatment method capable of improving enzymolysis efficiency of raw starch

A pretreatment and raw starch technology, which is applied in the field of starch sugar production, can solve the problems of reducing raw starch hydrolysis efficiency and binding limitations, and achieve the effects of promoting viscosity reduction, reducing production costs, and reducing evaporation energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Influence of heat preservation pretreatment on enzymolysis properties of starch granules

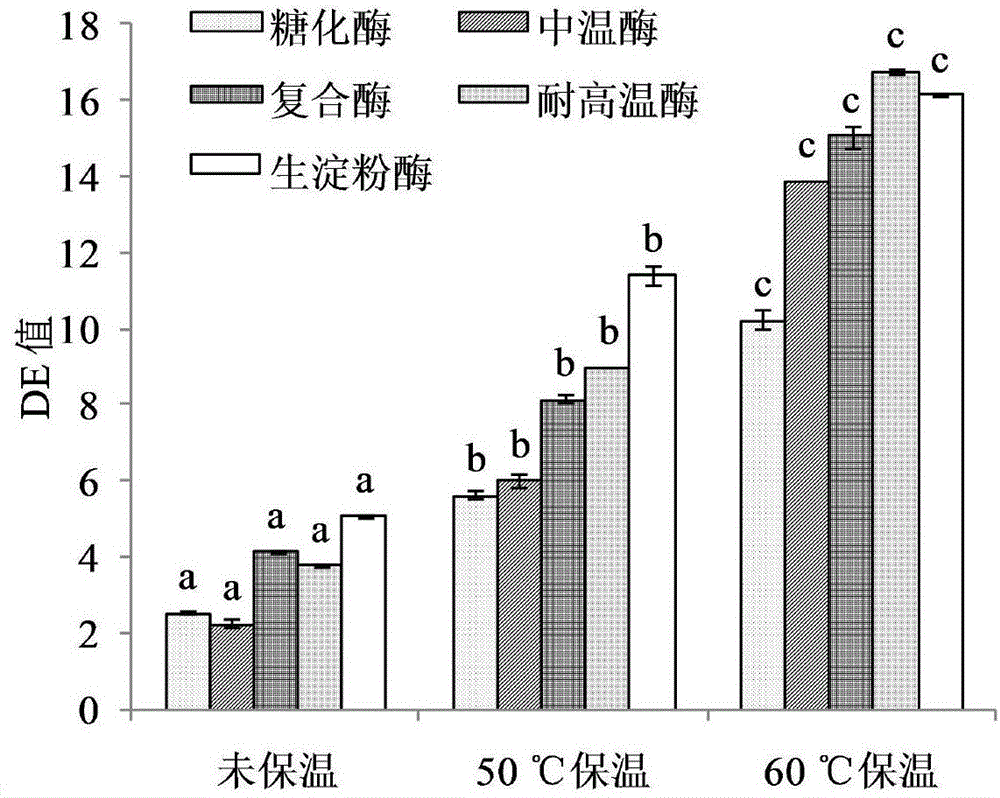

[0027] Take the starch that has been heat-preserved or not, add raw amylase, medium-temperature α-amylase, high-temperature-resistant α-amylase, glucoamylase and compound enzyme (medium-temperature α-amylase + high-temperature-resistant α-amylase) to react for 30 minutes respectively , and then determine the reducing sugar content (based on glucose). Measurement results such as figure 1 shown.

[0028] The reaction results showed that the heat preservation treatment could improve the enzymatic hydrolysis efficiency of the above four enzymes and compound enzymes on common corn starch. After 30 minutes of enzymatic hydrolysis of untreated starch, the DE value was around 5; and after the starch was incubated at 50°C, the enzymatic hydrolysis efficiency of medium-temperature α-amylase, high-temperature-resistant α-amylase, glucoamylase and compound enzymes all increased M...

Embodiment 2

[0029] Example 2 Effect of heat preservation pretreatment on the enzymatic properties of different concentrations of starch milk

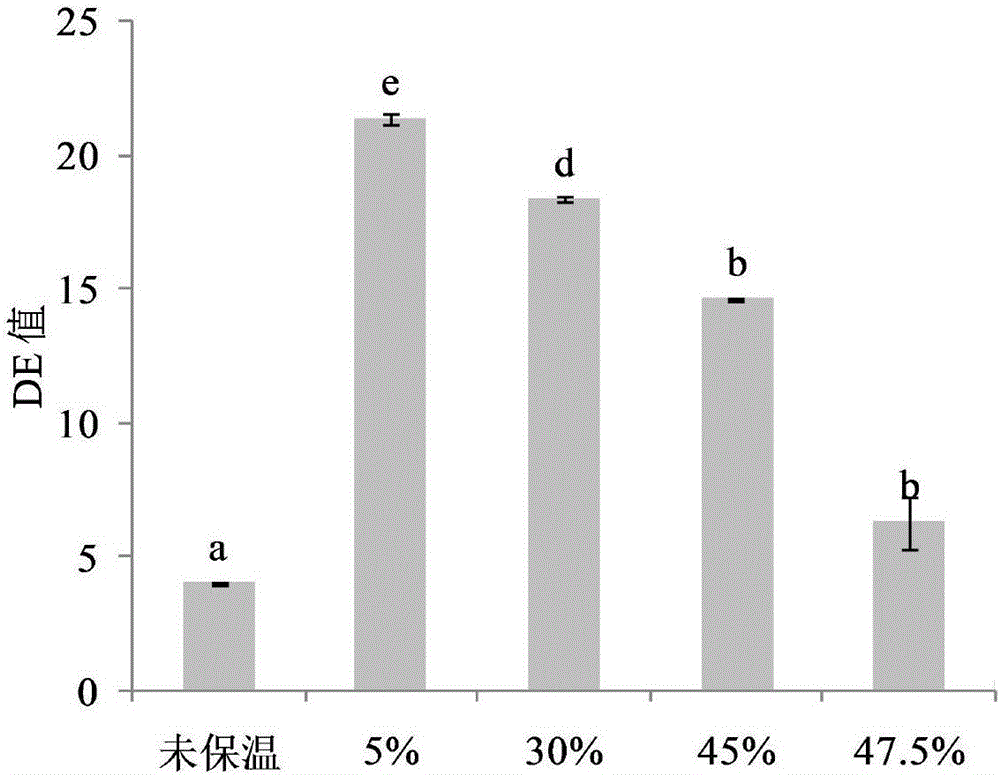

[0030] 5%, 30%, 45% and 47.5% (w / w mass fraction) of ordinary cornstarch milk were prepared respectively and added to a four-neck flask, adjusted to pH 6.0, and stirred at 60°C for 30min. Prepare starch milk with a concentration of 5%, add high-temperature resistant α-amylase and react at 40°C for 30 minutes, and then measure the reducing sugar content (calculated as glucose). Taking common cornstarch without insulation treatment as a control, the measurement results are as follows: figure 2 shown.

[0031] The reaction results showed that the enzymatic hydrolysis efficiency of ordinary corn starch milk with mass fraction of 5%, 30% and 45% was significantly improved after heat preservation pretreatment, and the lower the concentration of starch milk, the more obvious the effect of heat preservation pretreatment. Starch milk with a concentration...

Embodiment 3

[0032] Example 3 Effect of incubation pretreatment time on the enzymatic properties of 45% (w / w mass fraction) starch milk

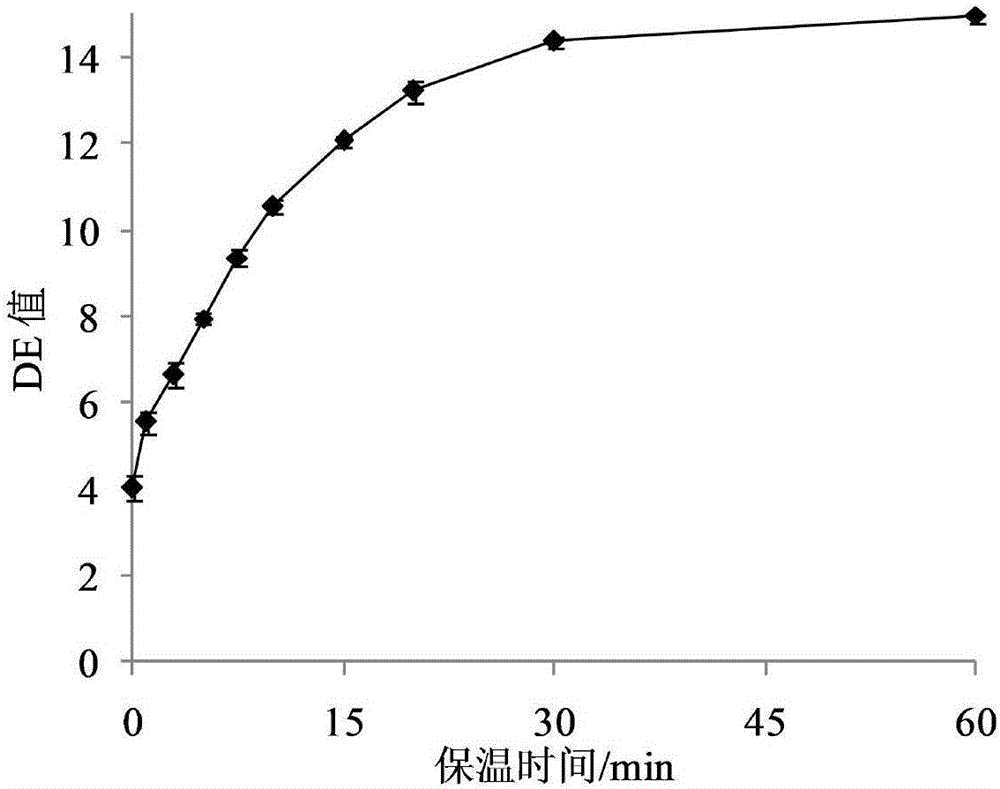

[0033] Prepare 45% common cornstarch milk and add it to a four-neck flask, adjust the pH to 6.0, stir at 60°C for 0, 1, 3, 5, 7.5, 10, 15, 20, 30, and 60 minutes, then cool down to 40 ℃, add high-temperature-resistant α-amylase to react for 30 minutes, and then measure the reducing sugar content (calculated by glucose). Measurement results such as image 3 shown.

[0034] The results of the reaction showed that common corn starch granules were more likely to be hydrolyzed by enzymes with the prolongation of the holding time. And in the first 15 minutes of incubation, the enzyme sensitivity increased rapidly, then gradually slowed down and stabilized. The difference between 60 minutes and 30 minutes of heat preservation at 60 ℃ was not big, and the DE value of starch hydrolyzate reached 15, which was about four times that of untreated starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com