Method for fermenting L-lysine

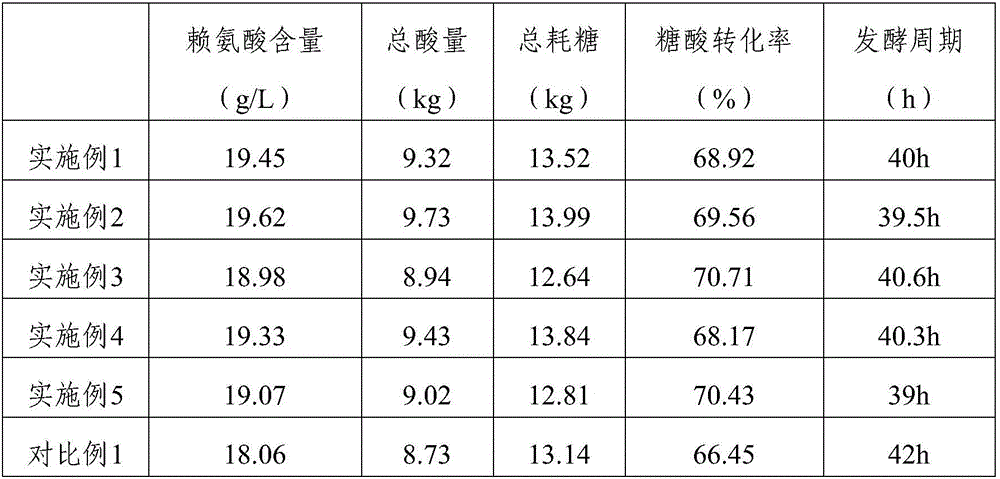

A technology of lysine fermentation and fermentation method, applied in the field of fermentation production of L-lysine, can solve the problems of low end-point lysine content, total acid content and sugar-acid conversion rate, high production cost, etc. The effect of promoting bacterial growth and lysine synthesis, increasing end-point lysine content and shortening fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The fermentation method of L-lysine in this embodiment includes three steps of lysine primary seed cultivation, lysine secondary seed cultivation and lysine fermentation cultivation. The specific operation of each step is as follows:

[0041] 1. Primary seed culture of lysine

[0042] Prepare lysine primary seed medium. Lysine primary seed culture medium comprises sucrose 20g / L in the present embodiment, magnesium sulfate 0.5g / L, potassium dihydrogen phosphate 1.5g / L, ammonium sulfate 9g / L, yeast extract powder 5g / L, threonine 0.5g / L, methionine 0.5g / L, monosodium glutamate 7g / L, sodium pyruvate 0.5g / L, calcium acetate 1g / L.

[0043] With the prepared lysine first-grade seed culture medium, adjust the pH value to 6.0 with 20% (volume ratio) potassium hydroxide solution, pass steam to heat up the culture medium to 121 ° C, sterilize for 20 minutes, and turn on the circulating water to cool down to 36°C and kept constant. Start stirring at 300rpm, introduce sterile ai...

Embodiment 2

[0053] The fermentation method of L-lysine in this embodiment includes three steps of lysine primary seed cultivation, lysine secondary seed cultivation and lysine fermentation cultivation. The specific operation of each step is as follows:

[0054] 1. Primary seed culture of lysine

[0055] Prepare lysine primary seed medium. Lysine primary seed culture medium comprises sucrose 40g / L in the present embodiment, magnesium sulfate 1.5g / L, potassium dihydrogen phosphate 1.5g / L, ammonium sulfate 10g / L, yeast extract powder 8g / L, threonine 0.4g / L, methionine 0.4g / L, monosodium glutamate 9g / L, sodium pyruvate 0.6g / L, calcium acetate 3g / L. Adjust the prepared primary lysine seed medium to pH 6.0 with 20% potassium hydroxide, heat the medium to 121°C with steam, sterilize it for 20 minutes, and cool it down to 37°C with circulating water and keep it constant. Start stirring at 350rpm, introduce sterile air according to the ventilation ratio of 1:0.5, adjust the tank pressure to 0.0...

Embodiment 3

[0064] The fermentation method of L-lysine in this embodiment includes three steps of lysine primary seed cultivation, lysine secondary seed cultivation and lysine fermentation cultivation. The specific operation of each step is as follows:

[0065] 1. Primary seed culture of lysine

[0066] Prepare lysine primary seed medium. In the present embodiment, the lysine primary seed culture medium comprises 35g / L of sucrose, 0.7g / L of magnesium sulfate, 0.7g / L of potassium dihydrogen phosphate, 11g / L of ammonium sulfate, 7g / L of yeast extract powder, threonine 0.6g / L, methionine 0.46g / L, monosodium glutamate 7g / L, sodium pyruvate 0.5g / L, sodium acetate 1.5g / L.

[0067] Adjust the prepared primary lysine seed medium to pH 6.3 with 20% potassium hydroxide, heat the medium to 121°C by steaming it, sterilize it for 20 minutes, and cool it down to 37°C with circulating water and keep it constant. Start stirring at 300rpm, introduce sterile air according to the ventilation ratio of 1:0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com