A kind of preparation method of hyaluronic acid blended nanofiber immobilized enzyme

A nanofiber, hyaluronic acid technology, applied in the direction of fixation on/in organic carriers, fiber processing, fiber chemical characteristics, etc., can solve the problem of providing a mild microenvironment, easy shedding of modified materials, and poor biocompatibility and other problems, to achieve the effect of improving biocompatibility and water retention, good water retention performance and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

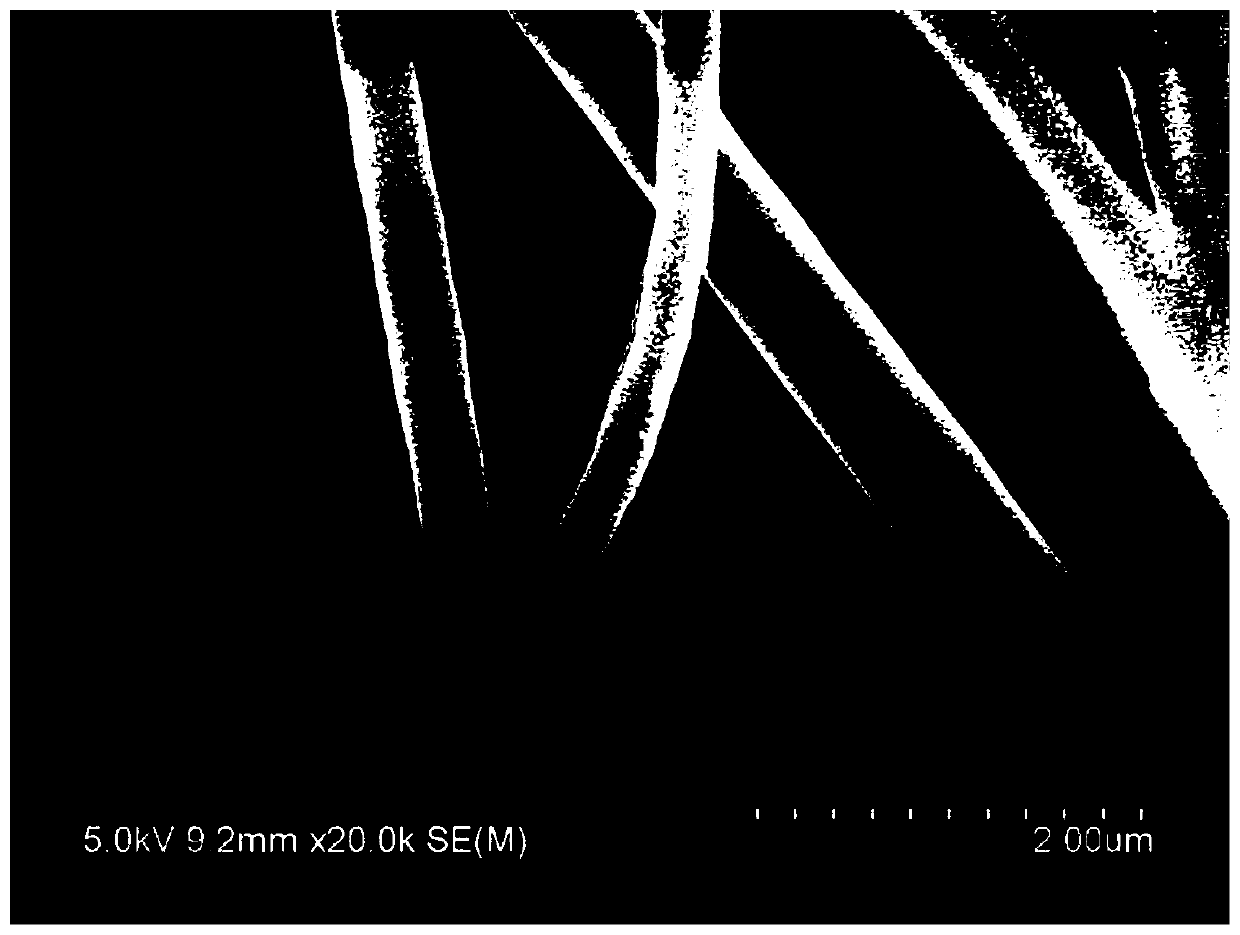

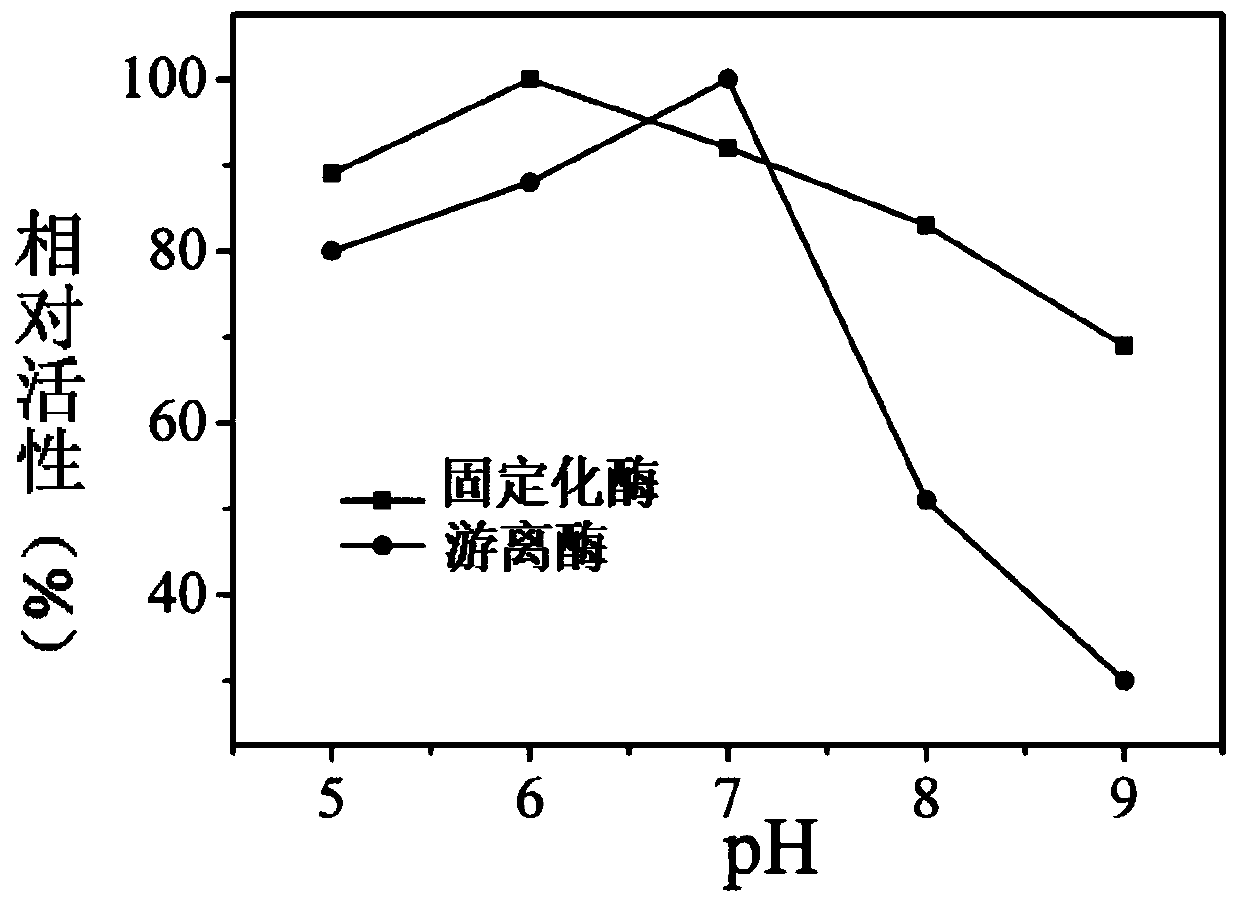

[0039] A preparation method for immobilizing enzymes in hyaluronic acid blended nanofibers, comprising the following steps:

[0040] (1) Configuration of hyaluronic acid solution

[0041] Measure 1.5mL of DMF solution and 1.5mL of distilled water into a test tube, weigh 4mg of sodium hyaluronate solid with an electronic balance, add it and dissolve to obtain a sodium hyaluronate solution.

[0042] (2) Configuration of PMA-AA binary interpolymer

[0043]Dissolve 2mL of acrylic acid and 14mL of methyl acrylate in 40mL of N,N-dimethylformamide (DMF), add 0.2-0.3g of azobisisopropionitrile, fill with nitrogen gas for 10-12min, and place at 60-80°C Heat in a constant temperature water bath and react for 15 to 24 hours to obtain a viscous, transparent and uniform PMA-PAA solution. (3) Configuration of spinning precursor

[0044] Measure 5mL of PMA-PAA solution and add 3mL of sodium hyaluronate solution, and shake fully to obtain the spinning precursor solution.

[0045] (4) Prep...

Embodiment 2

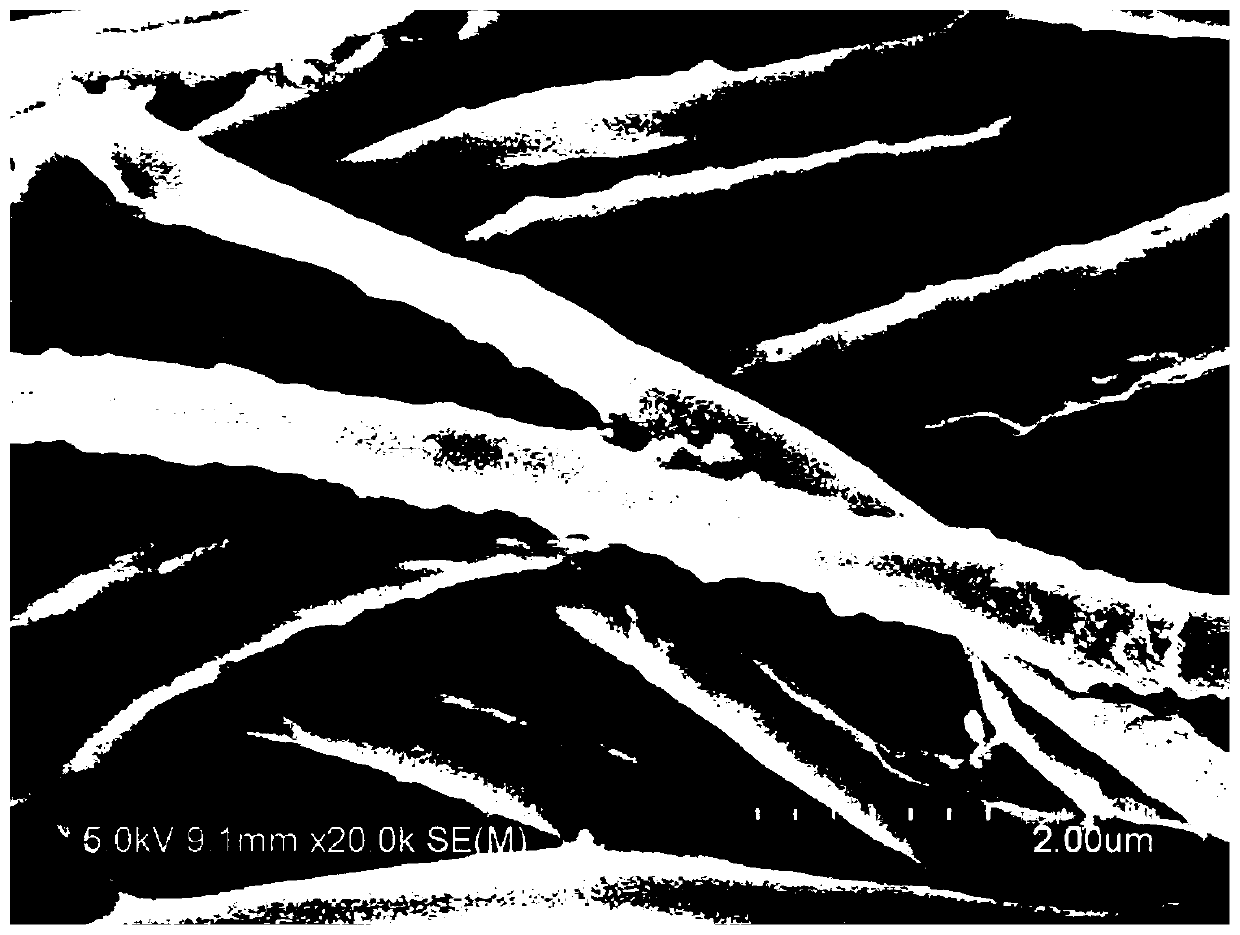

[0051] A preparation method for immobilizing enzymes in hyaluronic acid blended nanofibers, comprising the following steps:

[0052] (1) Configuration of hyaluronic acid solution

[0053] Measure 1.5mL of DMF solution and 1.5mL of distilled water into the test tube, weigh 4mg of sodium hyaluronate solid with an electronic balance, add it and dissolve to obtain a sodium hyaluronate solution.

[0054] (2) Configuration of PMA-AA binary interpolymer

[0055] Dissolve 2mL of acrylic acid and 14mL of methyl acrylate in 40mL of N,N-dimethylformamide (DMF), add 0.2-0.3g of azobisisopropionitrile, fill with nitrogen gas for 10-12min, and place at 60-80°C Heat in a constant temperature water bath and react for 15 to 24 hours to obtain a viscous, transparent and uniform PMA-PAA solution.

[0056] (3) Configuration of spinning precursor

[0057] Measure 5mL of PMA-PAA solution, add 0.5mL of sodium hyaluronate solution, and shake fully to obtain the spinning precursor solution.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com