Food-grade dishwashing liquid and preparation method thereof

A dishwashing liquid and food-grade technology, applied in the field of food-grade dishwashing liquid and its preparation, can solve the problems of being unsuitable for human consumption, the dishwashing liquid is ingested into the human body, and has no benefits, and achieves good decontamination and low cost. , good hydrophilic and lipophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

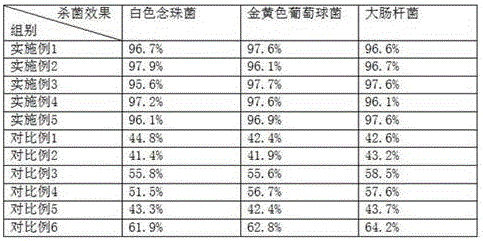

Examples

Embodiment 1

[0014] A food-grade dishwashing liquid, consisting of the following components in parts by weight: 54 parts of stearyl citric acid, 39 parts of deionized water, 19 parts of sodium stearyl fumarate, 3 parts of charoyl fermented product, grape skin 5 parts of extract, 21 parts of Magnolia officinalis leaf extract product.

[0015] Further, the preparation method of the charoalgae fermentation product is as follows: the setting condition is that the ratio of solid to liquid is 1:10 ( m / V ), cellulase ACCF-4740 addition 2%, temperature 55 ℃, pH 4.5, reaction time 1.3 h; after cellulase hydrolysis, inactivate enzyme in boiling water bath for 15 min, centrifuge at 9000 r / min, collect supernatant Obtain the chara cellulase hydrolyzate; after the chara enzymatic hydrolyzate is inactivated, adjust the pH value to 6.2-6.6, autoclave (121 ℃, 20 min), and then inoculate MRS medium with a volume fraction of 1% to activate The Pediococcus pentosaceae solution was transferred to the Char...

Embodiment 2

[0019] A food-grade dishwashing liquid, consisting of the following ingredients in parts by weight: 53 parts of stearyl citric acid, 38 parts of deionized water, 18 parts of sodium stearyl fumarate, 4 parts of charoyl fermented product, grape skin Extract 4 parts, Magnolia officinalis leaf extract product 18 parts.

[0020] Further, the preparation method of the charoalgae fermentation product is as follows: the setting condition is that the ratio of solid to liquid is 1:10 ( m / V ), cellulase ACCF-4740 addition 2%, temperature 55 ℃, pH 4.5, reaction time 1.3 h; after cellulase hydrolysis, inactivate enzyme in boiling water bath for 15 min, centrifuge at 9000 r / min, collect supernatant Obtain the chara cellulase hydrolyzate; after the chara enzymatic hydrolyzate is inactivated, adjust the pH value to 6.2-6.6, autoclave (121 ℃, 20 min), and then inoculate MRS medium with a volume fraction of 1% to activate The Pediococcus pentosaceae solution was transferred to the Charophyt...

Embodiment 3

[0024]A food-grade detergent, which is composed of the following components in parts by weight: 55 parts of stearyl citric acid, 40 parts of deionized water, 29 parts of sodium stearyl fumarate, 4 parts of charoyl fermented product, grape skin 5 parts of extract, 25 parts of Magnolia officinalis leaf extract product.

[0025] Further, the preparation method of the charoalgae fermentation product is as follows: the setting condition is that the ratio of solid to liquid is 1:10 ( m / V ), cellulase ACCF-4740 addition 2%, temperature 55 ℃, pH 4.5, reaction time 1.3 h; after cellulase hydrolysis, inactivate enzyme in boiling water bath for 15 min, centrifuge at 9000 r / min, collect supernatant Obtain the chara cellulase hydrolyzate; after the chara enzymatic hydrolyzate is inactivated, adjust the pH value to 6.2-6.6, autoclave (121 ℃, 20 min), and then inoculate MRS medium with a volume fraction of 1% to activate The Pediococcus pentosaceae solution was transferred to the Charoph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com