Integrated reaction device for preparing aromatic hydrocarbon through biomass pyrolysis-catalytic cracking and application method

A biomass pyrolysis and catalytic cracking technology, which is applied in the field of biomass pyrolysis-catalytic cracking to produce aromatic hydrocarbons integrated reaction device, can solve the problems of poor pyrolysis efficiency, low quality, blocked pipes and valves, etc., to improve utilization efficiency, improve quality and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

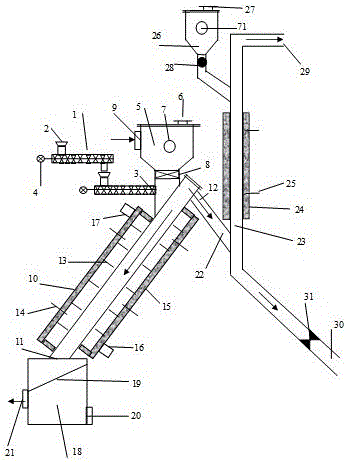

[0027] An integrated reaction device for producing aromatics from biomass pyrolysis-catalytic cracking, comprising a biomass pyrolysis furnace 10, a catalytic cracking reactor 23, a filler sampling device, a catalytic filler feeder 26, and a biomass pyrolysis furnace 10 Biochar collector 18 below;

[0028] The biomass pyrolysis furnace 10 is cylindrical, including an inner pyrolysis furnace pipeline and an outer ceramic insulation layer 15, and a heating channel is arranged between the inner layer pyrolysis furnace pipeline and the outer ceramic insulation layer 15; The top of the pyrolysis furnace pipeline is closed, and its upper end is provided with a pyrolysis furnace outlet 12; the lower end of the ceramic insulation layer 15 is provided with a flue gas inlet 16 communicated with the heating channel, and the upper end of the ceramic insulation layer 15 is provided with a gas inlet 16 communicated with the heating channel. Smoke outlet 17;

[0029] Described biochar col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com