Carbon-titanium water-based resin flame-retarding paint and preparation method of carbon-titanium water-based resin flame-retarding paint

A carbon-titanium water-based, flame-retardant coating technology, applied in the field of steel anti-corrosion coatings, can solve the problems of high construction cost, poor drying, slow drying speed, etc., and achieve the goal of reducing the difficulty of coating process, reducing construction cost, and reducing the number of construction passes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with examples.

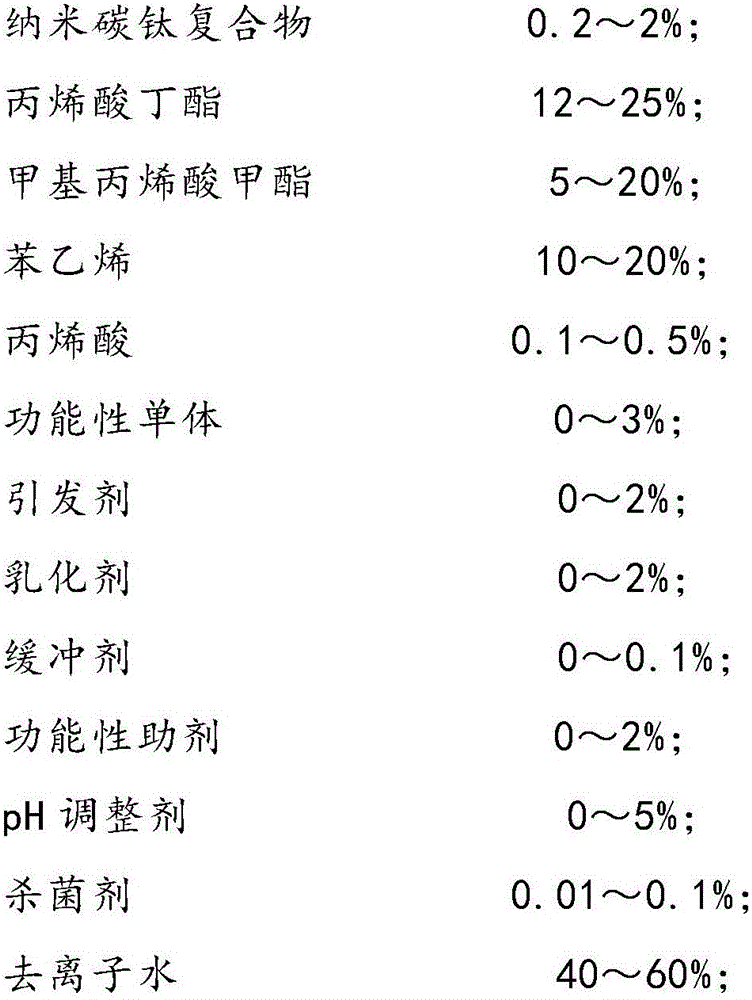

[0033] First prepare carbon-titanium modified acrylic resin according to the following steps:

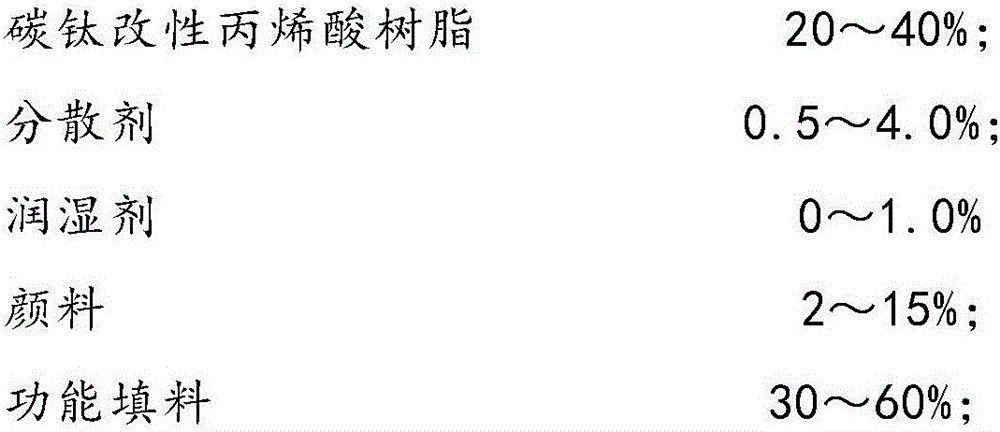

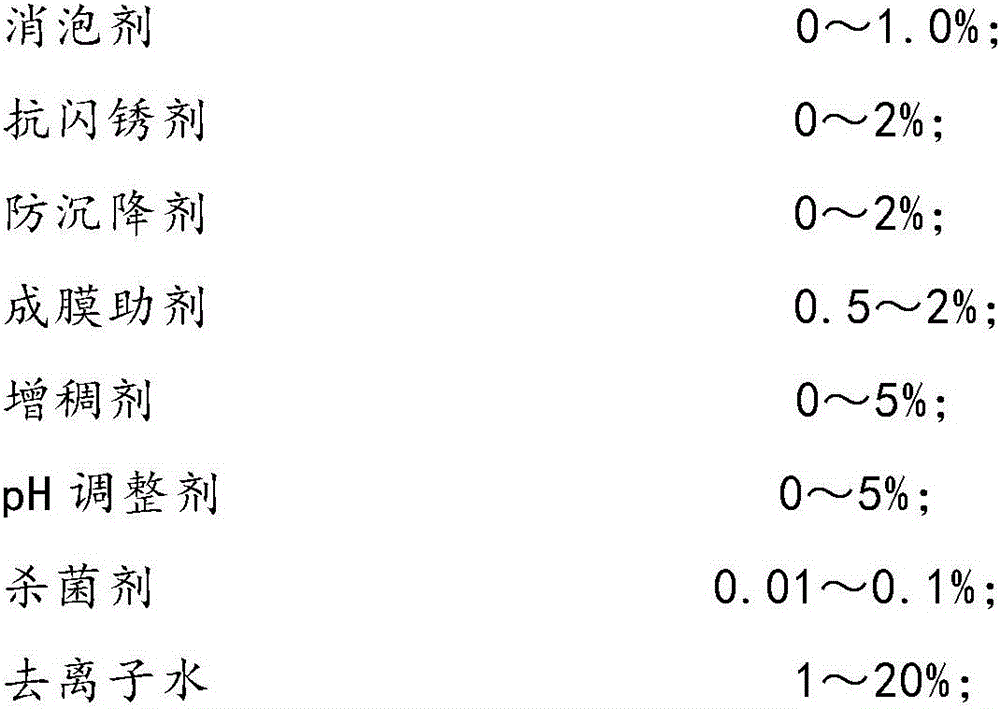

[0034] (1) Take the raw materials of the following quality:

[0035]

[0036] (2) Put 2400g of deionized water, 20g of nano-carbon-titanium composite and 5g of ammonium bicarbonate into the reactor and stir to raise the temperature to 88°C;

[0037] (3) 2300g deionized water, 10g nano-carbon-titanium composite and 20g sulfosuccinate are dropped into the pre-emulsification kettle under stirring state, drop into all butyl acrylate, methyl methacrylate, styrene and acrylic acid, stir for 30 Take out after minutes;

[0038] (4) Add the mixed liquid of step (3) into the reaction kettle that has been heated to 88° C. and stir;

[0039] (5) remove 200g ion water and be divided into two parts equally, ammonium persulfate is divided into two parts of 12g and 15g and be made into solution a and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com