A kind of preparation method of low temperature resistant modified plastic

A technology of low temperature resistance and modification, which is applied in the field of plastics to achieve the effects of maintaining life and function, enhancing low temperature resistance, and improving low temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The polyethylene resin, ABS resin, and polystyrene resin are uniformly mixed according to a mass ratio of 8:3:1 to obtain a mixture. 2.5% of the mass of the mixture is added with a compatibilizer, melt blended at 215°C, and then extruded and granulated. A resin material blend is obtained.

[0025] The ABS resin is an ABS resin with a viscosity average molecular weight of 90,000 to 130,000 prepared by a bulk polymerization method, the content of rubber formed by butadiene in the ABS resin is 7 wt.%, and the content of segment formed by acrylonitrile is 8 wt.% , The rest are segments formed by styrene, and the number average particle size of the rubber formed by butadiene in the ABS resin is 100-150 nm.

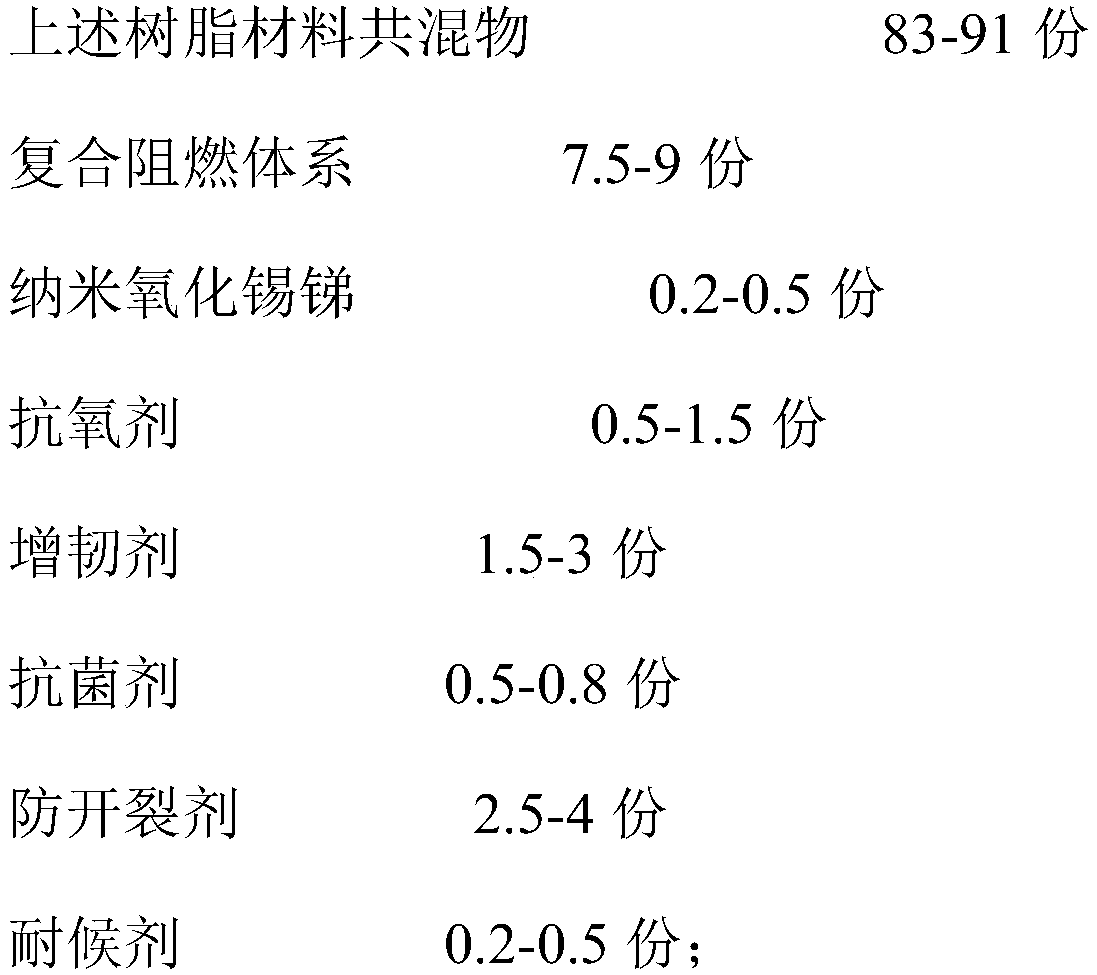

[0026] Ingredients in parts by weight as follows:

[0027]

[0028] Before use, the nano-tin antimony oxide is processed according to the following process: place the nano-tin antimony oxide in a 40KHz ultrasonic cleaner, and use absolute ethanol to sonicate for 30 minutes; af...

Embodiment 2

[0035] The polyethylene resin, ABS resin, and polystyrene resin are uniformly mixed according to a mass ratio of 9:2:3 to obtain a mixture, and 3% of the mass of the mixture is added with a compatibilizer, melt blended at 215-230°C and then extruded. Pellets to obtain a resin material blend.

[0036] The ABS resin is an ABS resin with a viscosity average molecular weight of 90,000 to 130,000 prepared by a bulk polymerization method, the content of rubber formed by butadiene in the ABS resin is 12 wt.%, and the content of segment formed by acrylonitrile is 15 wt.% , The rest are segments formed by styrene, and the number average particle size of the rubber formed by butadiene in the ABS resin is 100-150 nm.

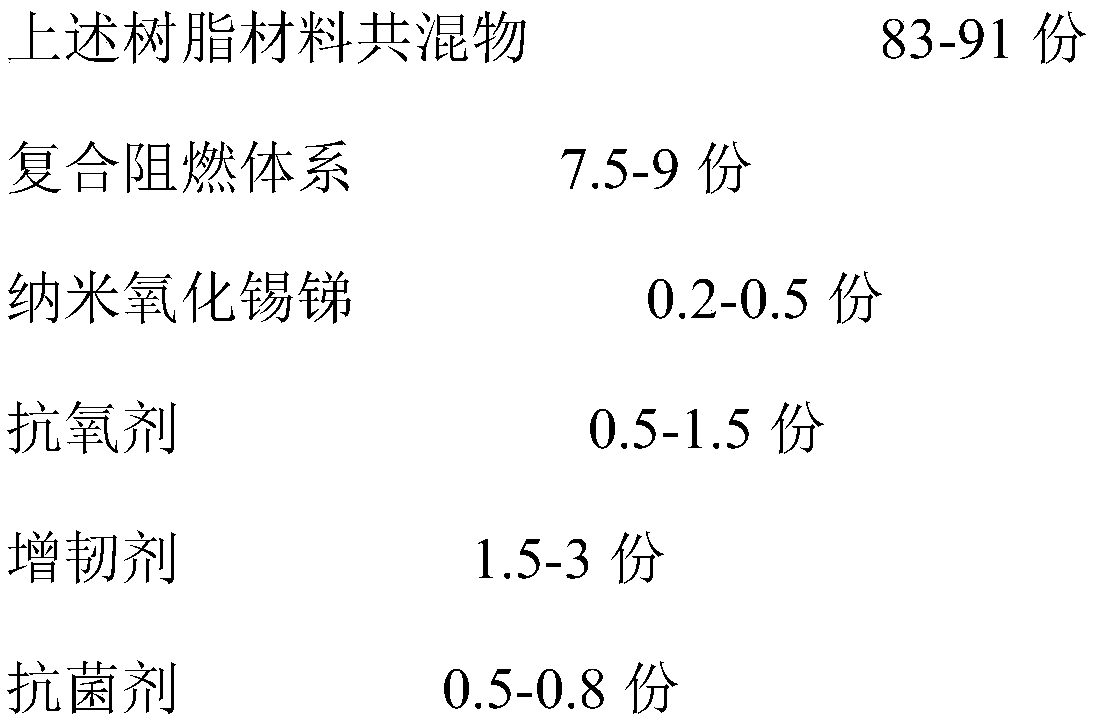

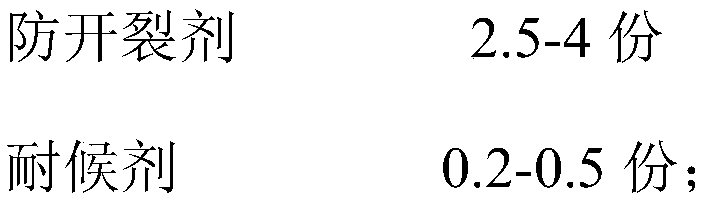

[0037] Ingredients in parts by weight as follows:

[0038]

[0039]

[0040] Before use, the nano-tin antimony oxide is processed according to the following process: place the nano-tin antimony oxide in a 45KHz ultrasonic cleaner, and use absolute ethanol to sonicate for 40 minu...

Embodiment 3

[0047] The polyethylene resin, ABS resin, and polystyrene resin are uniformly mixed according to a mass ratio of 10:6:3 to obtain a mixture. 4% of the mass of the mixture is added with a compatibilizer, melt blended at 230°C, and then extruded and granulated. A resin material blend is obtained.

[0048] The ABS resin is an ABS resin with a viscosity average molecular weight of 90,000 to 130,000 prepared by a bulk polymerization method. The content of rubber formed by butadiene in the ABS resin is 15 wt.%, and the content of segments formed by acrylonitrile is 25 wt.%. , The rest are segments formed by styrene, and the number average particle size of the rubber formed by butadiene in the ABS resin is 100-150 nm.

[0049] Ingredients in parts by weight as follows:

[0050]

[0051] Before use, the nano-tin antimony oxide is processed according to the following process: place the nano-tin antimony oxide in a 50KHz ultrasonic cleaning instrument, and use absolute ethanol to sonicate for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com