Antifreeze-resistant water pump gasket and preparation method thereof

A technology of antifreeze and gaskets, which is applied in the direction of mechanical equipment, coatings, engine components, etc., can solve the problems that the gaskets do not have antifreeze resistance, poor sealing effect, and poor service life, so as to improve the mechanical properties, Good protective effect, good extrusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

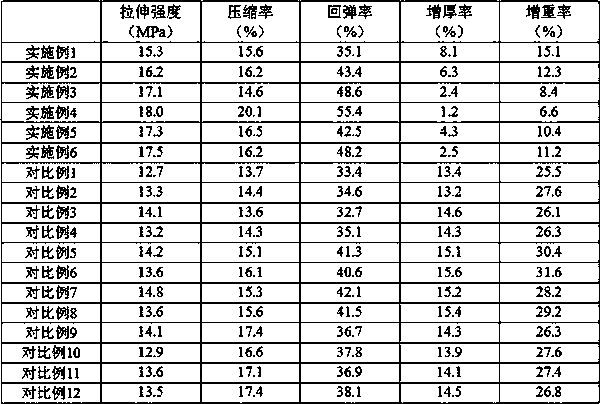

Examples

Embodiment 1

[0026] An antifreeze-resistant water pump gasket, comprising 100 parts of main material, 8 parts of mica powder, 20 parts of kaolin, 18 parts of talcum powder and 5 parts of coloring agent in parts by weight, including main materials and auxiliary materials, The main material includes antifreeze-resistant hydroxy silicone oil, styrene-butadiene rubber and fiber in a weight ratio of 3:40:55. The antifreeze-resistant hydroxy silicone oil includes 30 parts of hydroxy silicone oil and 2.5 parts of vulcanizing agent by weight ratio. 2 parts of vulcanization accelerator, 1 part of anti-aging agent.

[0027] The colorant is carbon black N330; the fiber is wollastonite fiber; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is triallyl isocyanurate; the anti-aging agent is anti-aging agent 4020.

[0028] The preparation method of described antifreeze-resistant water pump gasket, comprises the following steps:

[0029] (1) Mix antifreeze-resistant hydroxysilico...

Embodiment 2

[0035] An antifreeze-resistant water pump gasket, comprising 100 parts of main material, 3 parts of mica powder, 25 parts of kaolin, 20 parts of talcum powder and 6 parts of coloring agent in parts by weight. , the main material includes antifreeze-resistant hydroxy silicone oil substance, styrene-butadiene rubber and fiber in a weight ratio of 4:40:56, and the antifreeze-resistant hydroxy silicone oil substance includes 32 parts of hydroxy silicone oil and 3 parts of vulcanizing agent according to the weight ratio , 3 parts of vulcanization accelerator, 2 parts of anti-aging agent.

[0036] The colorant is carbon black N330; the fiber is wollastonite fiber; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is triallyl isocyanurate; the anti-aging agent is anti-aging agent 4020.

[0037] The preparation method of described antifreeze-resistant water pump gasket, comprises the following steps:

[0038] (1) Mix the antifreeze-resistant hydroxy silicone oi...

Embodiment 3

[0044] An antifreeze-resistant water pump gasket, including main materials and auxiliary materials in parts by weight, including 100 parts of main materials, 15 parts of mica powder, 30 parts of kaolin, 20 parts of talcum powder and 6 parts of coloring agent, The main material includes antifreeze-resistant hydroxy silicone oil substance, styrene-butadiene rubber and fiber weight ratio of 5:40:57, and the antifreeze-resistant hydroxy silicone oil substance includes 34 parts of hydroxy silicone oil and 2.8 parts of vulcanizing agent according to the weight ratio. 2.5 parts of vulcanization accelerator, 3 parts of anti-aging agent.

[0045] The colorant is carbon black N330; the fiber is attapulgite fiber; the vulcanizing agent is dicumyl peroxide; the vulcanization accelerator is triallyl isocyanurate; the anti-aging agent is anti-aging agent 4020.

[0046] The preparation method of described antifreeze-resistant water pump gasket, comprises the following steps:

[0047] (1) Mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com