ZIF@CNT modified polymer hybrid proton exchange membrane and preparation method thereof

A proton exchange membrane and polymer technology, applied in the field of polymer hybrid proton exchange membrane and its preparation, can solve the problems of no significant increase in proton conductivity, low absolute value, poor mechanical strength, etc., and achieve a good industrial production basis, The effect of low production cost and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

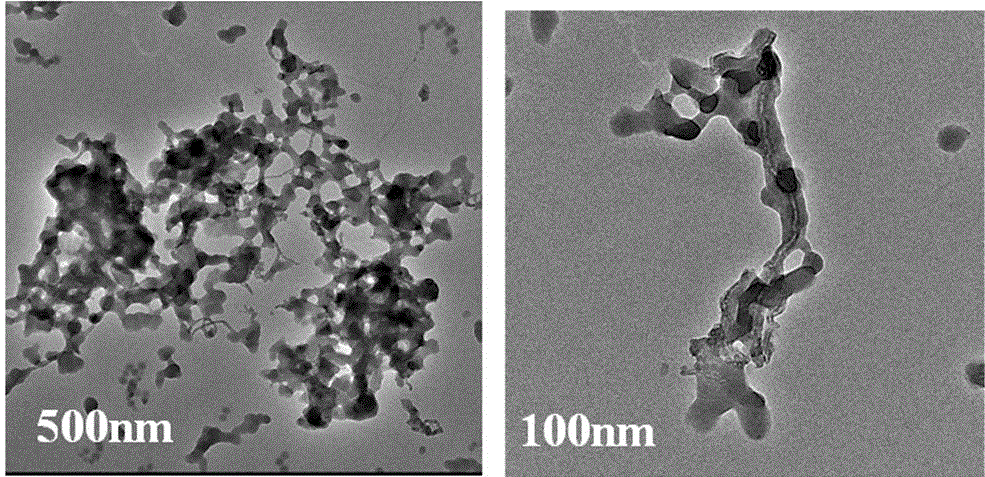

[0021] 1. Ultrasonic dispersion of 120mg CNT-COOH in 30 mL of methanol, then weighed 0.2971 g of zinc nitrate hexahydrate and 0.6568 g of 2-methylimidazole were dissolved in 15 mL of methanol, and then poured them into the above CNT-CCOH dispersion solution, and transferred to a 100 mL polytetrafluoroethylene liner, covered the lid and put it into the reaction kettle to seal it tightly, and then placed it in a constant temperature oven at 90 °C for 10 h, and the reaction product was separated by centrifugation. First, it was washed continuously with fresh methanol solvent, and the product was centrifuged and finally placed in an oven at 50 °C for 6 h to obtain ZIF@CNT composite particles.

[0022] 2. Take 200 mg of SPEEK (sulfonation degree 62%), add 3mL N,N-dimethylformamide, dissolve to form a SPEEK solution, add 0.5 wt% ZIF@CNT to the above polymer solution, and sonicate for 3h To disperse evenly; carefully pour the dispersion into a mold and quickly place it in an oven at ...

Embodiment 2

[0025] 1. Ultrasonic dispersion of 120mg CNT-COOH in 30 mL of methanol, then weighed 0.2971 g of zinc nitrate hexahydrate and 0.6568 g of 2-methylimidazole were dissolved in 15 mL of methanol, and then poured them into the above CNT-CCOH dispersion solution, and transferred to a 100 mL polytetrafluoroethylene liner, covered the lid and put it into the reaction kettle to seal it tightly, and then placed it in a constant temperature oven at 90 °C for 10 h, and the reaction product was separated by centrifugation. First, it was washed continuously with fresh methanol solvent, and the product was centrifuged and finally placed in an oven at 50 °C for 6 h to obtain ZIF@CNT composite particles.

[0026]2. Take 200 mg of SPEEK (sulfonation degree 62%), add 3mL N,N-dimethylformamide, dissolve to form a SPEEK solution, add 1 wt% ZIF@CNT to the above polymer solution, and sonicate for 3h To disperse evenly; carefully pour the dispersion into a mold and quickly place it in an oven at 60°...

Embodiment 3

[0028] 1. Ultrasonic dispersion of 120mg CNT-COOH in 30 mL of methanol, then weighed 0.2971 g of zinc nitrate hexahydrate and 0.6568 g of 2-methylimidazole were dissolved in 15 mL of methanol, and then poured them into the above CNT-CCOH dispersion solution, and transferred to a 100 mL polytetrafluoroethylene liner, covered the lid and put it into the reaction kettle to seal it tightly, and then placed it in a constant temperature oven at 90 °C for 10 h, and the reaction product was separated by centrifugation. First, it was washed continuously with fresh methanol solvent, and the product was centrifuged and finally placed in an oven at 50 °C for 6 h to obtain ZIF@CNT composite particles.

[0029] 2. Take 200 mg of SPEEK (sulfonation degree 62%), add 3mL N,N-dimethylformamide, dissolve to form a SPEEK solution, add 1.5wt% ZIF@CNT to the above polymer solution, and sonicate for 3h To disperse evenly; carefully pour the dispersion into a mold and quickly place it in an oven at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

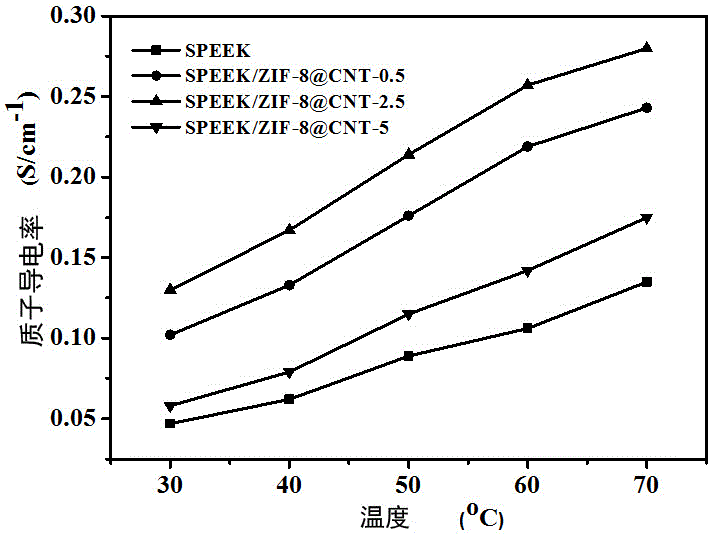

| Proton conductivity | aaaaa | aaaaa |

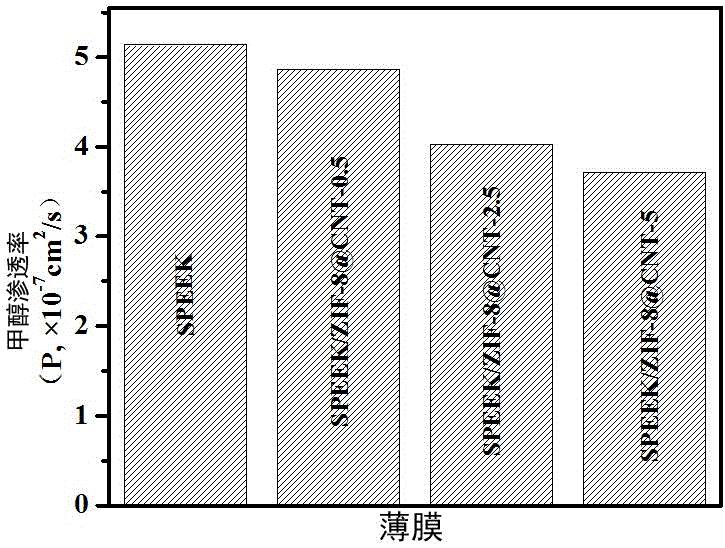

| Methanol permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com