A post-treatment method and device for preparing methionine

A post-processing device, methionine technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of inability to recover and recycle, increase environmental protection pressure, consume large amounts of electricity, etc. The effect of reducing environmental protection pressure and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

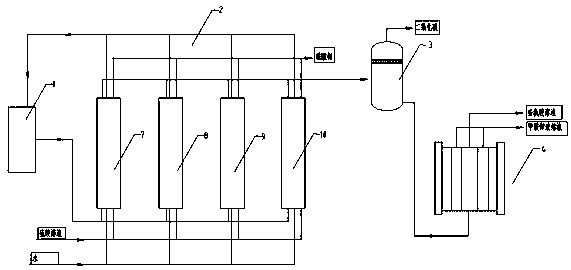

[0049] Example 1 A post-processing device for preparing methionine

[0050] A post-processing device for preparing methionine includes a microporous membrane filtration device 1, an acid resin acidification device 2, a gas-liquid separation tank 3, and an electrodialysis device 4; a microporous membrane filtration device 1, an acid resin acidification device 2, and a gas-liquid separation tank 3. The electrodialysis devices 4 are connected by pipelines;

[0051] The microporous membrane filtration device 1: adopts a microporous membrane structure with a pore size of 0.45-2 μm;

[0052] The acidic resin acidification device 2: includes acidification columns, the number of acidification columns is 4, namely the first acidification column 7, the second acidification column 8, the third acidification column 9, the fourth acidification column 10, between the four acidification columns The pipelines are connected through a three-way valve, and any three acidification columns can be...

Embodiment 2

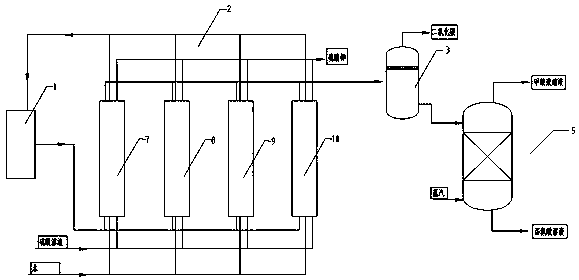

[0058] Example 2 A post-processing device for preparing methionine

[0059] A post-processing device for preparing methionine includes a microporous membrane filtration device 1, an acid resin acidification device 2, a gas-liquid separation tank 3, and an electrodialysis device 4; a microporous membrane filtration device 1, an acid resin acidification device 2, and a gas-liquid separation tank 3. The electrodialysis devices 4 are connected by pipelines;

[0060] The microporous membrane filtration device 1: adopts a microporous membrane structure with a pore size of 0.45-2 μm;

[0061] The acidic resin acidification device 2: includes acidification columns, the number of acidification columns is 4, that is, the first acidification column 7, the second acidification column 8, the third acidification column 9, the fourth acidification column 10, one of the four acidification columns The pipelines between them are connected through a three-way valve, and any three acidification ...

Embodiment 3

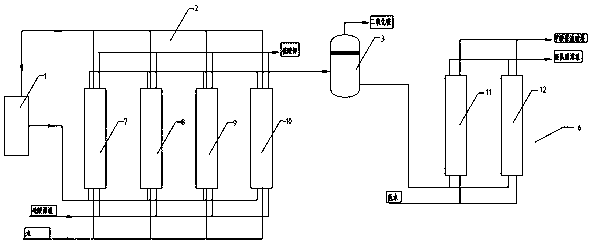

[0067] Example 3 A post-processing device for preparing methionine

[0068] A post-processing device for preparing methionine includes a microporous membrane filtration device 1, an acid resin acidification device 2, a gas-liquid separation tank 3, and a stripping tower 5; the microporous membrane filtration device 1, an acid resin acidification device 2, and a gas-liquid separation tank 3. The stripping towers 5 are connected by pipelines;

[0069] The microporous membrane filtration device 1: adopts a microporous membrane structure with a pore size of 0.45-2 μm;

[0070] The acid resin acidification device 2: includes acidification columns, the number of acidification columns is 4, that is, the first acidification column 7, the second acidification column 8, the third acidification column 9, the fourth acidification column 10, between the four columns The pipelines are connected through a three-way valve, and any three of the columns can be connected in series through valve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com