A kind of dense polymer concrete with high insulation and its preparation method and application

A high-insulation, polymer technology, used in the field of concrete preparation, can solve the problems of reducing the electrical properties and mechanical strength of concrete, and achieve the effects of increasing compactness, improving insulation and mechanical strength, and eliminating free water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

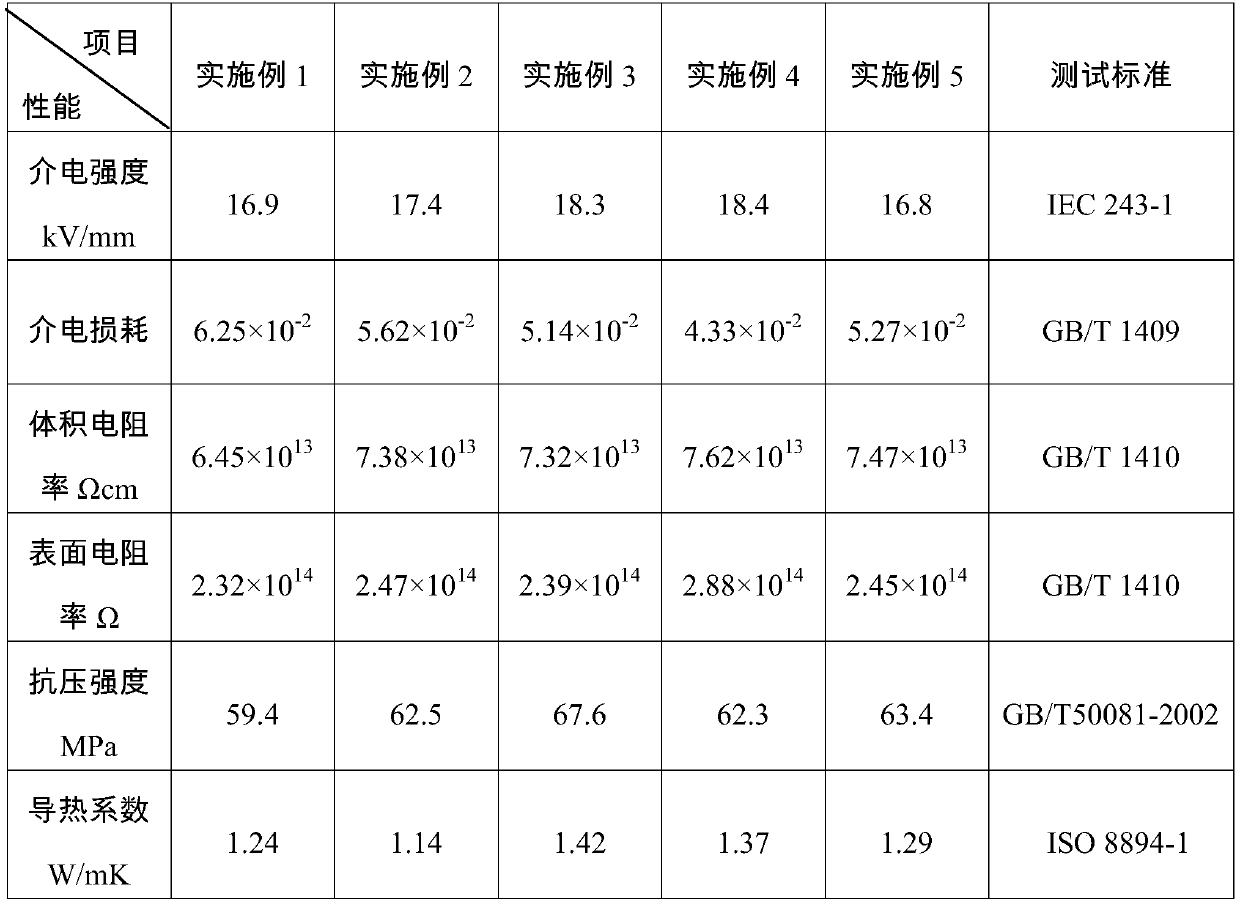

Examples

Embodiment 1

[0029] The invention provides a high-insulation dense polymer concrete and a preparation method thereof, comprising the following steps:

[0030] 1) Add 120g of ordinary Portland cement, 15g of wollastonite, 10g of mica, 10g of silica, and 0.1g of polycarboxylate water reducer into a 250mL stirring tank, and stir evenly; mix 54.2g of water, 0.01g of Deform W -098 water-based defoamer and 15g of styrene-acrylic emulsion are mixed evenly and then added to the above mixture, stirred evenly under the stirring at a rotating speed of 200r / min, and it becomes fluid;

[0031] 2) After the cement mortar is stirred for 5 minutes, use a vacuum pump to evacuate the stirring tank, keep the vacuum at 0.06MPa, and stir for 20 minutes;

[0032] 3) Pour the mixture into the mold, vibrate to make it level, then move it into the curing box, and cure it for 8 days at a temperature of 20°C and a relative humidity of 95%.

[0033] 4) The sample is taken out from the curing box, and cured in a dry ...

Embodiment 2

[0035] The invention provides a high-insulation dense polymer concrete and a preparation method thereof, comprising the following steps:

[0036] 1) Add 120g of ordinary Portland cement, 15g of wollastonite, 10g of mica, 10g of silica, and 0.1g of polycarboxylate water reducer into a 250mL stirring tank, and stir evenly; mix 53.5g of water, 0.01g of Deform W -098 water-based defoamer and 20g of styrene-acrylic emulsion are mixed evenly and then added to the above mixture, stirred evenly under the stirring at a rotating speed of 200r / min, and it becomes fluid;

[0037] 2) After the cement mortar is stirred for 5 minutes, use a vacuum pump to evacuate the stirring tank, keep the vacuum at 0.08MPa, and stir for 20 minutes;

[0038] 3) Pour the mixture into the mold, vibrate to make it level, then move it into the curing box, and cure it for 8 days at a temperature of 20°C and a relative humidity of 95%.

[0039] 4) The sample is taken out from the curing box, and cured in a dry ...

Embodiment 3

[0041] The invention provides a high-insulation dense polymer concrete and a preparation method thereof, comprising the following steps:

[0042] 1) Add 120g of ordinary Portland cement, 15g of wollastonite, 10g of mica, 10g of silica, and 0.1g of polycarboxylate water reducer into a 250mL stirring tank, and stir evenly; mix 52.4g of water, 0.01g of Deform W -098 water-based defoamer and 25g of styrene-acrylic emulsion are mixed evenly and then added to the above mixture, stirred evenly under the stirring at a rotating speed of 200r / min, and it is in a fluid state;

[0043] 2) After the cement mortar is stirred for 5 minutes, use a vacuum pump to evacuate the stirring tank, keep the vacuum at 0.01MPa, and stir for 20 minutes;

[0044]3) Pour the mixture into the mold, vibrate to make it level, then move it into the curing box, and cure it for 8 days at a temperature of 20°C and a relative humidity of 95%.

[0045] 4) The sample is taken out from the curing box, and cured in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com