Secondarily formed automotive glass hot bending mould

An automotive glass, secondary molding technology, applied in glass production, glass molding, glass remolding and other directions, can solve the problems of bulging, wave quality, molding position deviation, etc., to improve optical performance, reduce optical distortion, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

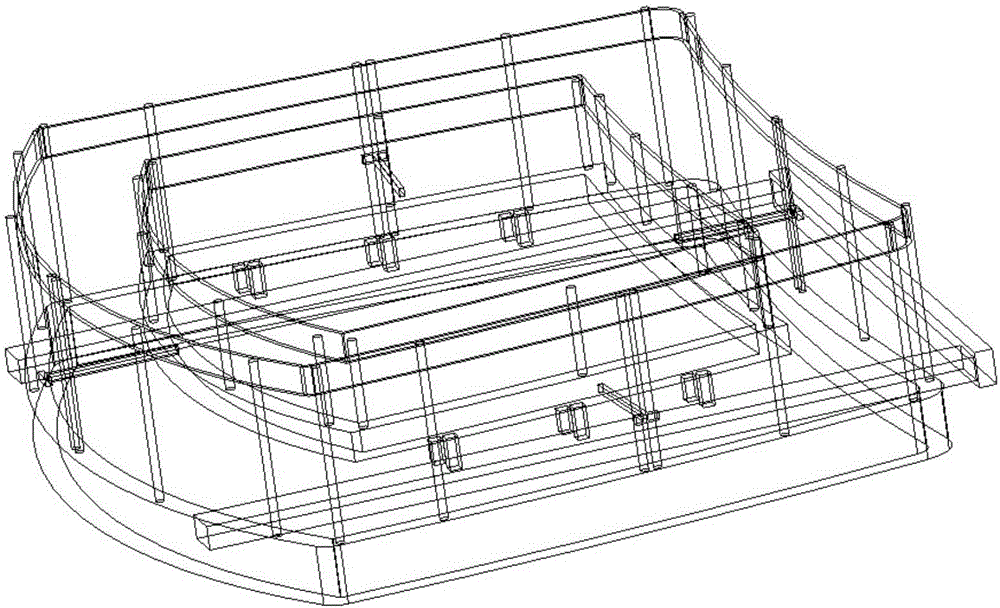

[0020] see figure 1 , figure 1 It is a structural schematic diagram of the inner molding frame of a secondary forming auto glass hot-bending mold of the present invention before falling. Such as figure 1 As shown, the secondary molding automobile glass hot bending mold includes: an inner molding frame 1 and an outer molding frame 2 . The radian of the inner molding frame 1 is small, which is beneficial to the pre-forming of the middle part of the glass. The bottom of the first lower frame (i.e. the bottom frame) of the inner molding frame 1 is equipped with six support rods 5, and three upper support rods 5 are respectively installed on the parallel sides of the bottom frame, and the three upper support rods 5 on both sides are opposite to the inner molding The lines in frame 1 are symmetrical to each other. Four connecting rods 6 are installed on the periphery of the bottom frame of the inner molding frame 1 . The four connecting rods 6 are respectively connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com