Oily sludge drying and burning integrated treatment technology

A treatment process and sludge drying technology, applied in dewatering/drying/concentrating sludge treatment, incinerators, petroleum industry, etc., can solve problems such as waste of resources and environmental pollution, and achieve the effect of ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

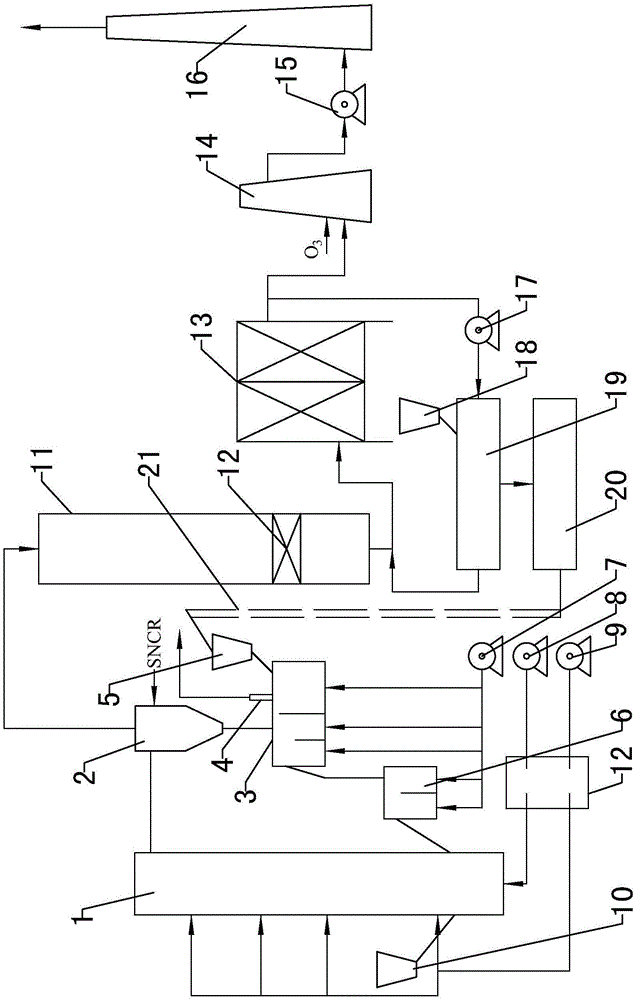

[0029] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0030] Refer to attached figure 1 : an oily sludge drying and incineration integrated treatment process, comprising the following steps:

[0031] Feed, transport the oily sludge to the high-temperature flue gas drying unit; collect the oily sludge to the oily sludge feeding device, and transport it to the high-temperature flue gas drying unit through the oily sludge feeding device;

[0032] Drying, the high-temperature flue gas drying unit uses wind drying to repeatedly dry the oily sludge, and the dried sludge is collected in a centralized manner; the high-temperature flue gas is used to dry the oily sludge with a water content of 60-80%. The dried flue gas is discharged into the flue gas circulation again;

[0033] Pyrolysis, the concentrated collected dried sludge is transported to the pyrolysis unit, the pyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com