Treatment method of fluoride-containing wastewater and application

A treatment method and technology for wastewater, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increased operating costs, poor sedimentation performance of suspensions, strict operating conditions, etc. To achieve the effect of mud-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

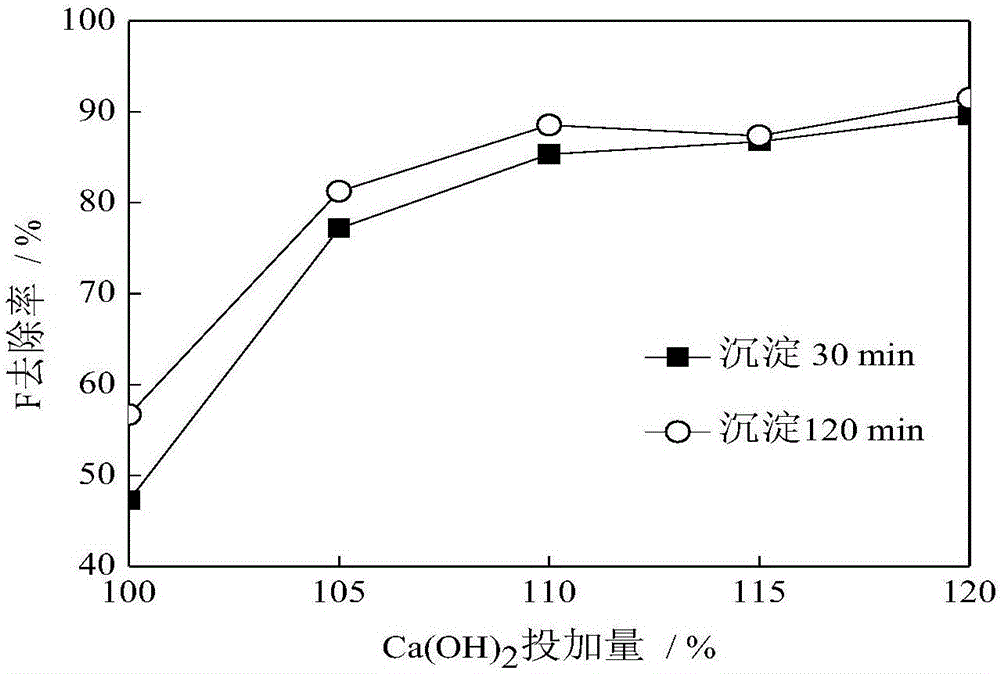

[0052] Embodiment 2—dosing Ca(OH) first 2 , then add CaCl 2 (two-step method)

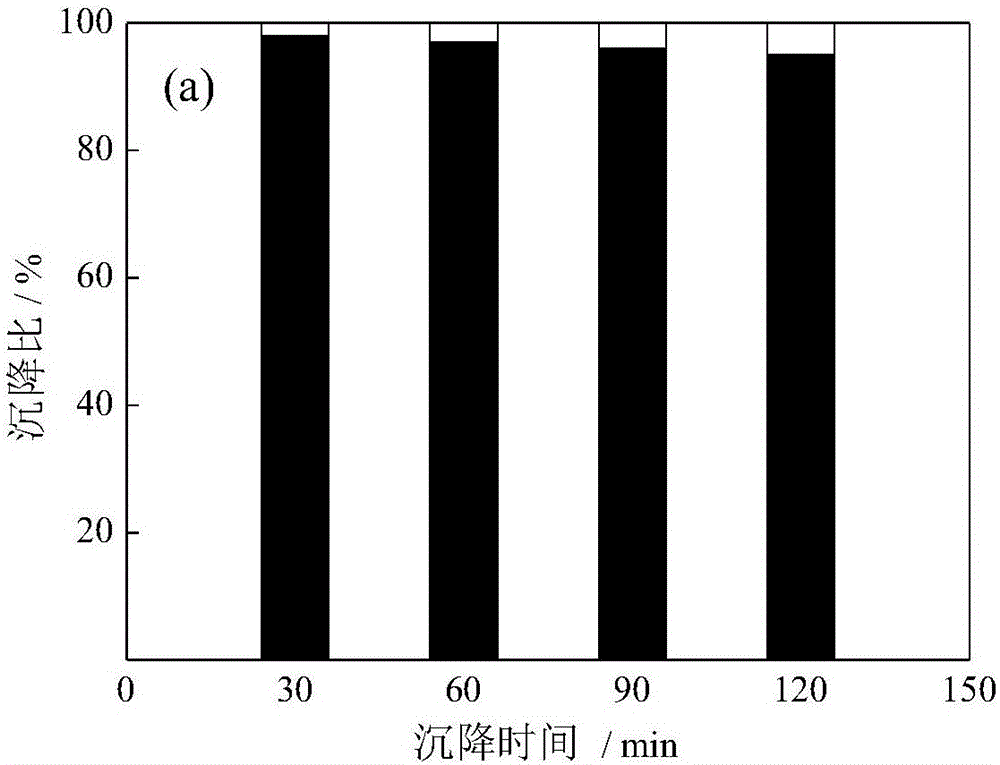

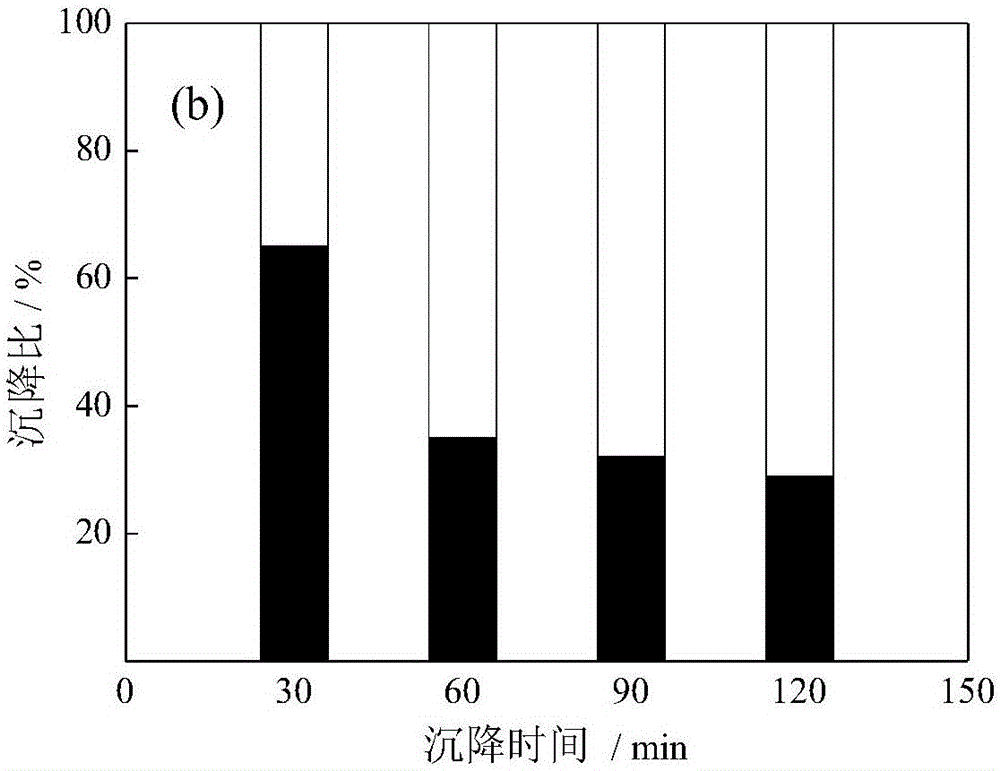

[0053] Add Xmol Ca(OH) to the fluorine-containing wastewater at a temperature of 60°C and a pH of 8 2 , after stirring and reacting at a speed of 150r / min for 30min, continue to add Ymol CaCl 2 , stirring and reacting for 30 min at a speed of 150 r / min. In order to achieve the purpose of comparison with the one-step method of Example 1, investigate the settling performance of the mud-water mixture after the reaction of the two modes, making X be Ca 2+ 110% of the theoretical dosage of ions, Y is Ca 2+ 95% of the theoretical dosage of ions.

[0054] Result as shown in Figure 2, (a) is the one-step method of embodiment 1, (b) is the two-step method of implementation 2. Compared with the one-step method, the settling performance after the two-step method has been significantly improved. When standing for 30 minutes, the supernatant accounted for 35% of the volume of the entire mixed solution, an...

Embodiment 3

[0059] In actual engineering, the water quality composition of raw water is difficult to be constant. In order to investigate whether the optimal conditions obtained in the research are applicable to other water quality conditions, F - Raw water with a concentration of 1000, 2500, 5000, 7500 and 10000 mg / L was operated according to the following one-step method and two-step method respectively, adding Ca 2+ The theoretical dosage of ions is 110% of Ca(OH) 2 and 95% CaCl 2 , compare the fluorine removal efficiency (standing for 360min) and the sedimentation performance of the mixed solution between the one-step method and the two-step method, the results are as follows image 3 and 4.

[0060] One-step method - a treatment method for high-fluorine wastewater, comprising the following steps: simultaneously adding Ca(OH) to high-fluorine wastewater 2 and CaCl 2 , stirring and reacting for 30 minutes; wherein, the temperature of the high-fluorine wastewater is 60°C and the pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com