Method for preparing nitrogen-doped porous graphite by one-step hydrothermal method

A porous graphene, nitrogen-doped technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of cumbersome process, high energy consumption, low production efficiency, etc., achieve simple process, excellent catalytic performance, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Feed according to the mass ratio of graphene oxide to hydrogen peroxide and ammonia 1:0.1:30. Get 40mL concentration and be the graphene oxide aqueous solution of 7.5mg / mL, put it into 100mL polytetrafluoroethylene reactor liner, add 10mL mass fraction as 0.3% hydrogen peroxide solution and 30mL mass fraction as 28-30% ammonia solution. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and subjected to a hydrothermal reaction in an oven at 180° C. for 6 hours to obtain nitrogen-doped porous graphene.

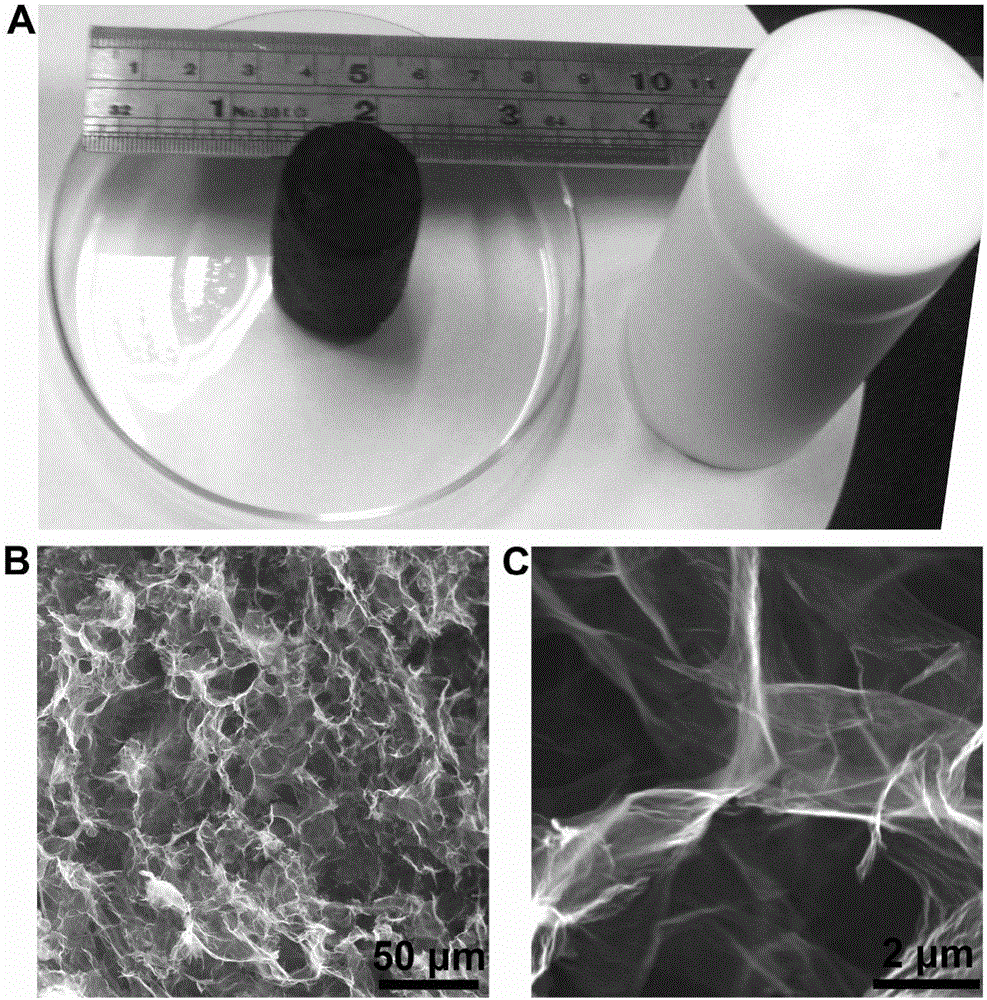

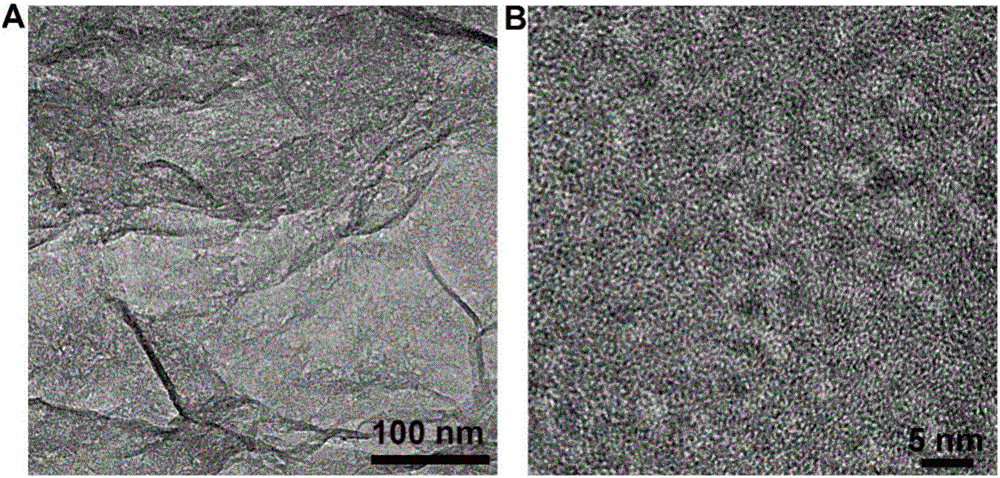

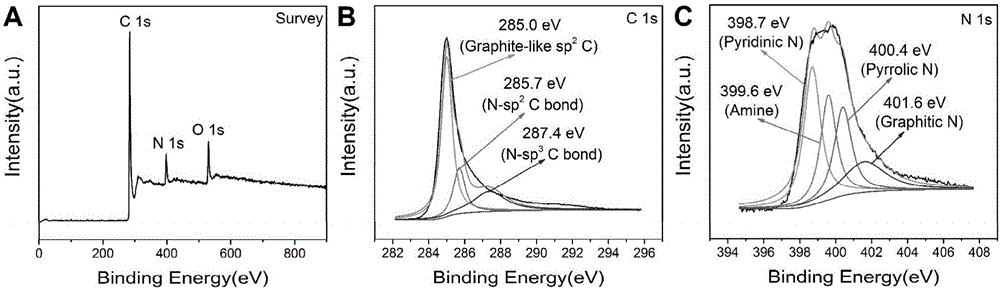

[0021] In order to fully understand the structural characteristics and properties of the nitrogen-doped porous graphene prepared in this example, SEM, TEM, XPS, adsorption-desorption and pore size distribution tests were carried out on it. Such as figure 1 As shown in -A, graphene oxide nanosheets are assembled into cylindrical hydrogels after hydrothermal reaction, and scanning electron microscope images confirm that the prepared nitrogen-dope...

Embodiment 2

[0023] Feed according to the mass ratio of graphene oxide to hydrogen peroxide and ammonia 1:0.05:0.05. Take 75mL concentration of 4mg / mL graphene oxide aqueous solution, put it into a 100mL polytetrafluoroethylene reactor liner, add 4.5mL hydrogen peroxide solution with a mass fraction of 0.3% and 0.05mL with a mass fraction of 28- 30% ammonia solution. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and subjected to a hydrothermal reaction in an oven at 130° C. for 24 hours to obtain nitrogen-doped porous graphene.

Embodiment 3

[0025] Feed according to the mass ratio of graphene oxide to hydrogen peroxide and ammonia 1:0.4:20. Take 50mL of graphene oxide aqueous solution with a concentration of 3mg / mL, put it into a 100mL polytetrafluoroethylene reactor liner, add 20mL of hydrogen peroxide solution with a mass fraction of 0.3% and 10mL with a mass fraction of 28-30% of ammonia solution. The uniformly mixed reactants were put into a hydrothermal reaction kettle, and subjected to a hydrothermal reaction in an oven at 150° C. for 8 hours to obtain nitrogen-doped porous graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com