Method for extracting endohedral metallofullerene

A technology of metallofullerene and extraction method, which is applied in the field of extraction of embedded metallofullerene, can solve the problems of not being able to adapt to the large-scale production of fullerene, waste of materials, and low purity of fullerene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

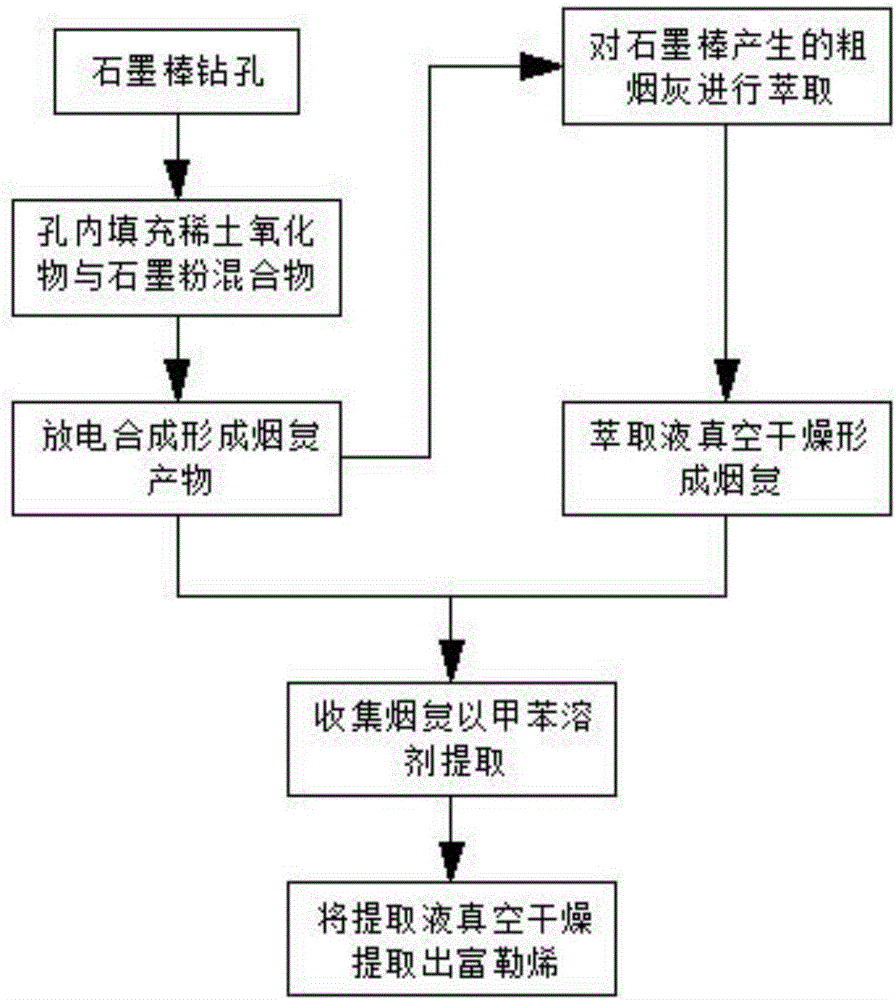

[0024] An extraction method for embedded metallofullerenes, the specific steps of the extraction method for embedded metallofullerenes are as follows:

[0025] S1: Drill out the spectral grade graphite rod The deep holes are filled with pre-treated mixtures of various rare earth oxides and graphite powders. The rare earth oxides are dried and dehydrated at a high temperature of 280°C for 3.5 hours. The ratio of rare earth atoms to carbon atoms in the mixture is 1: 50;

[0026] S2: Roasting the filled graphite rod at 1700°C for 3 hours under vacuum conditions to change rare earth oxides into rare earth carbides;

[0027] S3: at 1.1 x 10 4 Discharge synthesis is carried out under the protection of Pa's helium, and a large amount of soot is produced during the discharge, and carbon deposition rods are produced at the end of the cathode. During the discharge synthesis process, the current is 140A and the voltage is 25V;

[0028] S4: Exchange the electrodes, and reverse dischar...

Embodiment 2

[0036] An extraction method for embedded metallofullerenes, the specific steps of the extraction method for embedded metallofullerenes are as follows:

[0037] S1: Drill out the spectral grade graphite rod The deep hole is filled with a mixture of pretreated various rare earth oxides and graphite powder. The rare earth oxide is dried and dehydrated at a high temperature of 300°C for 4.5 hours. The ratio of rare earth atoms to carbon atoms in the mixture is 1: 50;

[0038] S2: Calcining the filled graphite rod at 1900°C for 4 hours under vacuum conditions to change rare earth oxides into rare earth carbides;

[0039] S3: at 1.3×10 4 Discharge synthesis is carried out under the protection of Pa's helium gas, and a large amount of soot is produced during discharge, and carbon deposition rods are produced at the end of the cathode. During the discharge synthesis process, the current is 180A and the voltage is 35V;

[0040] S4: Exchange the electrodes, and reverse discharge, so...

Embodiment 3

[0048] An extraction method for embedded metallofullerenes, the specific steps of the extraction method for embedded metallofullerenes are as follows:

[0049] S1: Drill out the spectral grade graphite rod The deep holes are filled with pre-treated mixtures of various rare earth oxides and graphite powder. The rare earth oxides are dried and dehydrated at 290°C for 4 hours. The ratio of rare earth atoms to carbon atoms in the mixture is 1:50 ;

[0050] S2: Roast the filled graphite rod at a high temperature of 1800°C for 3.5 hours under vacuum conditions to change the rare earth oxide into rare earth carbide;

[0051] S3: at 1.2 x 10 4 Discharge synthesis is carried out under the protection of Pa's helium, and a large amount of soot is produced during the discharge, and carbon deposition rods are produced at the end of the cathode. During the discharge synthesis process, the current is 160A and the voltage is 30V;

[0052] S4: Exchange the electrodes, and reverse discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com