Hose unloading device

A rubber hose and catheter technology, applied in the field of rubber hose feeding device, can solve the problems of difficult quality assurance, slow running speed, low efficiency, etc., and achieve the effects of reasonable structural design, high production efficiency, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments.

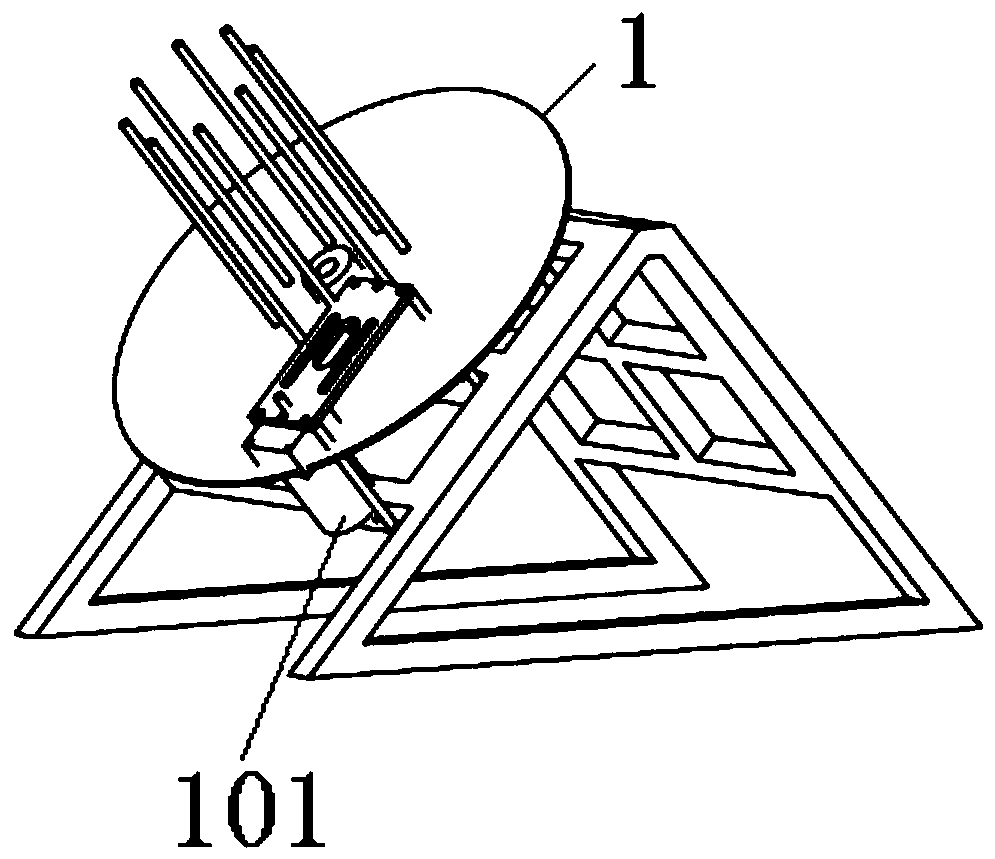

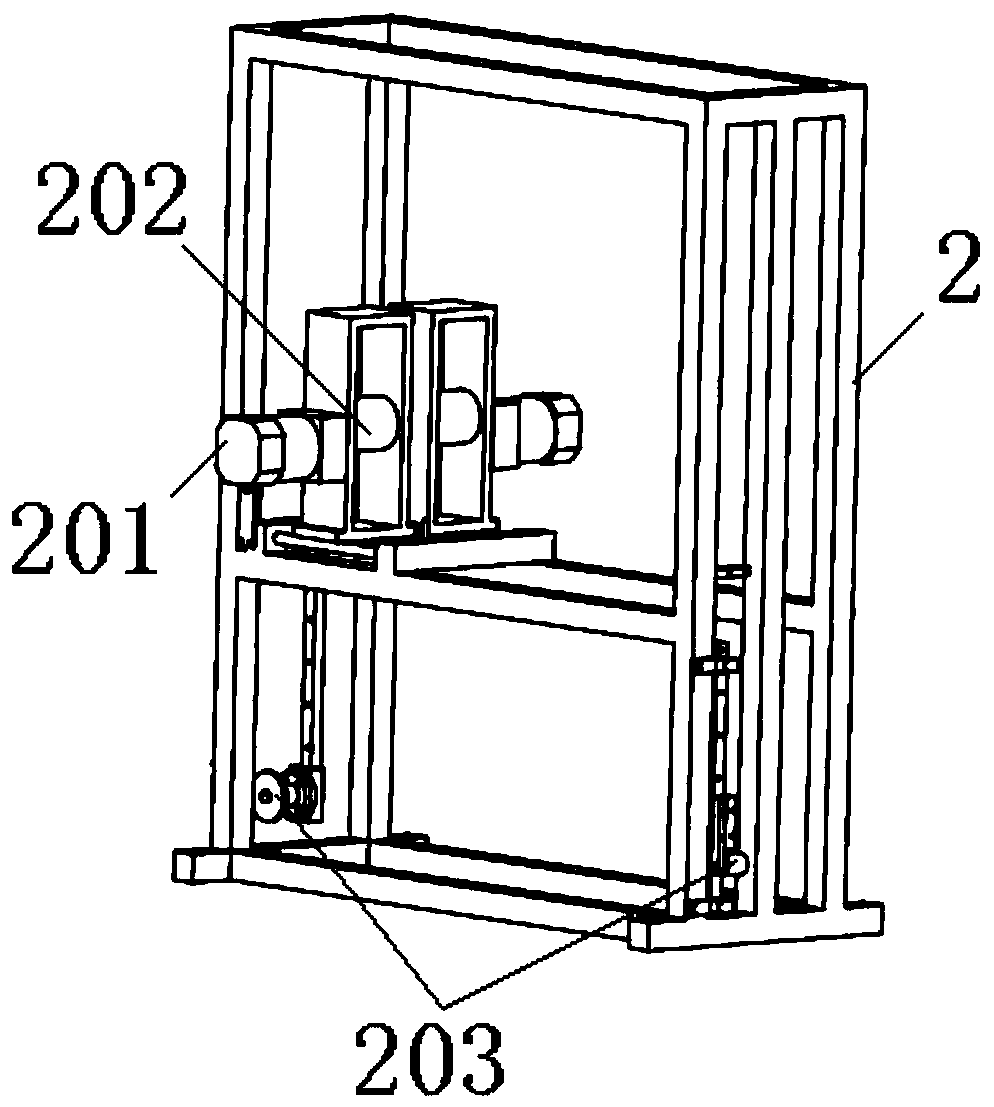

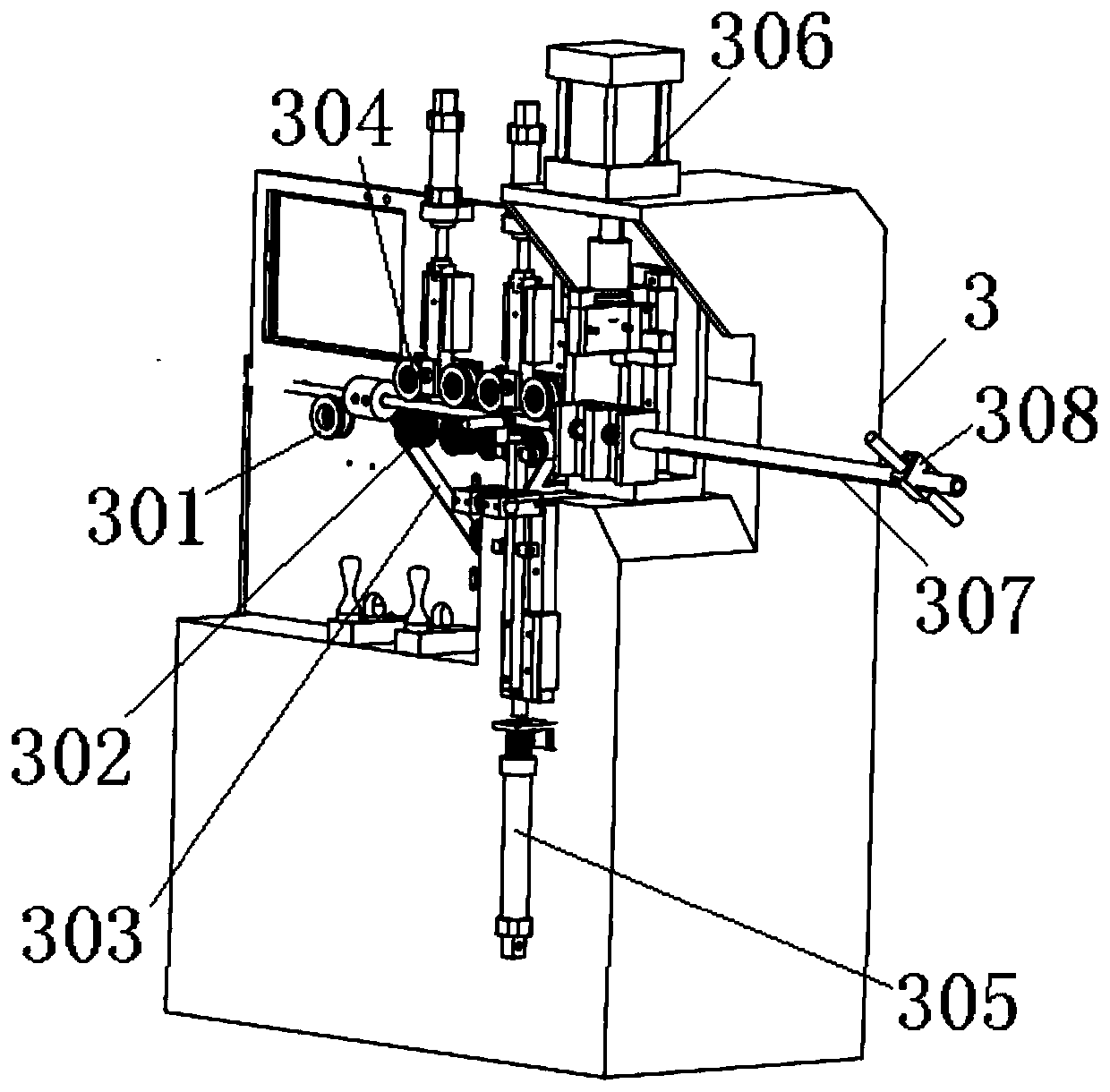

[0025] Such as Figure 1 to Figure 3 As shown, the hose blanking device includes a feeding tray 1 and a feeding rack 2 arranged in sequence, and a hose cutting and blanking machine.

[0026] The coiled hose is sleeved on the feeding tray 1, passing through the feeder 2 in the middle, and the hose is fed to the hose cutting machine, and the hose is cut off by the hose cutting machine, and the material is automatically unloaded.

[0027] The feeding tray 1 includes a rotating tray and a support, and the support is provided with a driving motor 101 for driving the rotating tray to rotate. Among them, the bracket is a triangular frame, and the rotating plate is inclined to facilitate feeding. The drive motor drives the rotating disk to rotate, and the end of the rubber tube is not easy to pull off.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com