Adjustable installation device and method for tantalum heater

A technology for installing devices and heaters, which is applied in metal processing, manufacturing tools, metal processing equipment, etc. It can solve the problems of difficulty in ensuring the position of each layer of tubes, high technical requirements for installers, and damage to the glass-lined surface of tantalum tubes. The effect of repeatable efficiency, low labor intensity and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

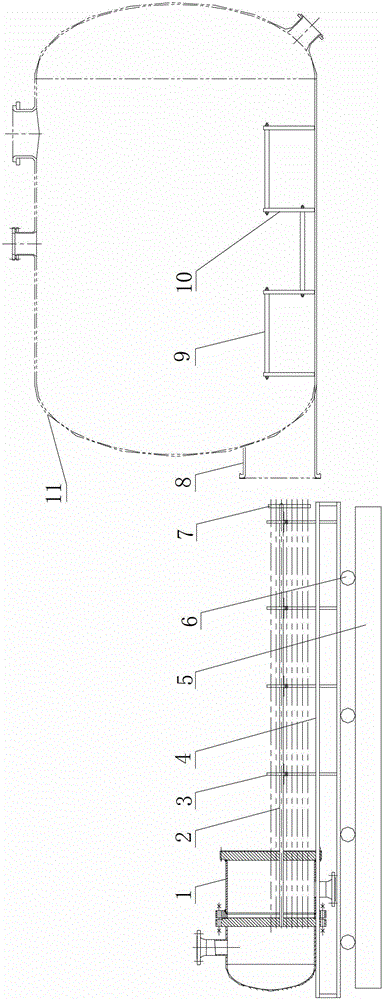

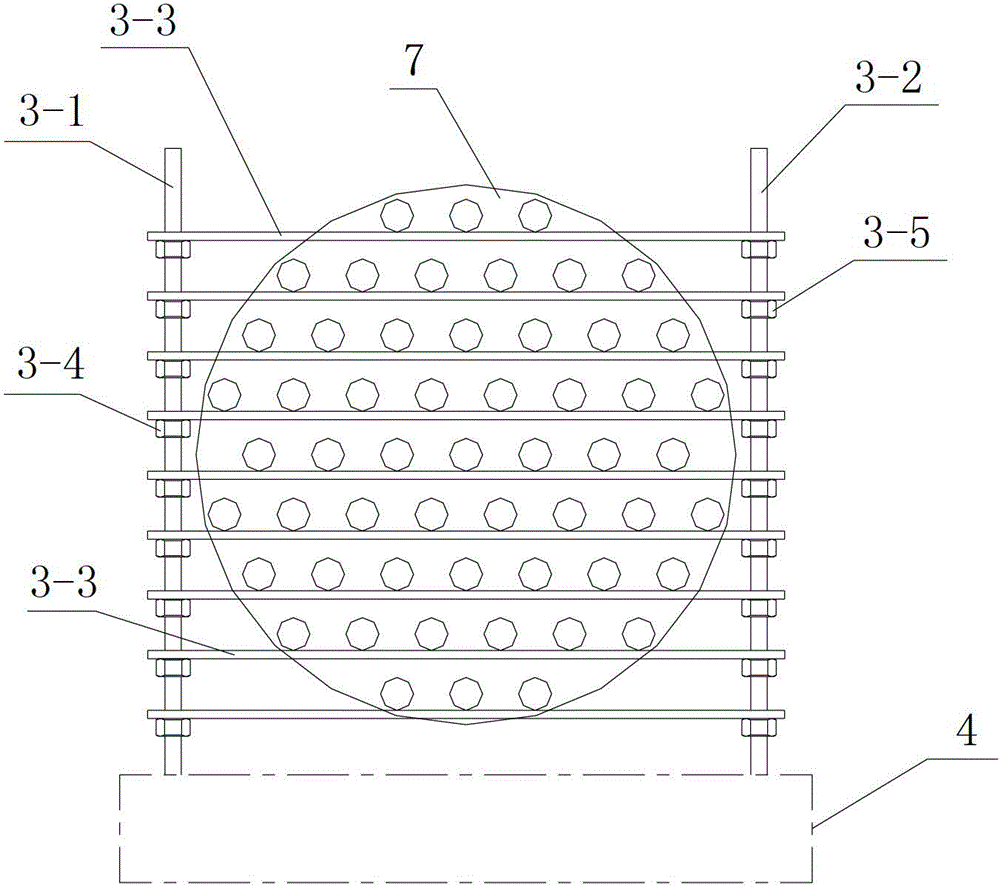

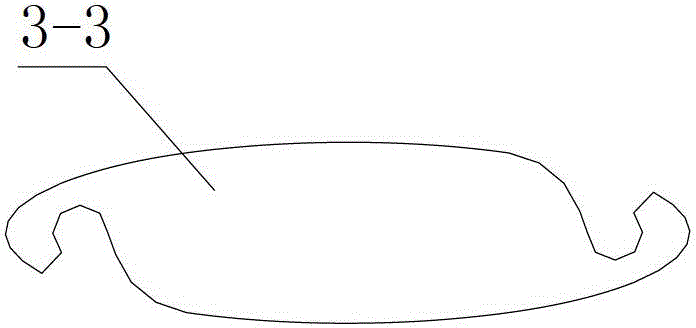

[0044] Such as figure 1 An adjustable mounting device for a tantalum heater is shown, which includes a horizontal temporary support stand 5, which drives the tantalum heater 1 to be installed to move forward on the horizontal temporary support stand 5 and is installed in the evaporator 11. Bracket 4, the walking mechanism installed on the bottom of the horizontal bracket 4, the adjustable bracket 3 that supports the tantalum heating tube bundle 2 that needs to be installed with the tantalum heater 1 from front to back, and the adjustable bracket 3 that is set on the tantalum heating tube bundle 2 and can be installed along the The mounting plate 7 for the tantalum heating tube bundle 2 to move back and forth, the multiple adjustable brackets 3 have the same structure and size, and the multiple adjustable brackets 3 are installed on the horizontal bracket 4 from front to back. The tantalum heating tube bundle 2 includes a plurality of heating tubes arranged in layers from top t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com