Automatic containing machine for window film waste edges

An automatic, window film technology, applied in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as unfavorable processing efficiency, large number of workers, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

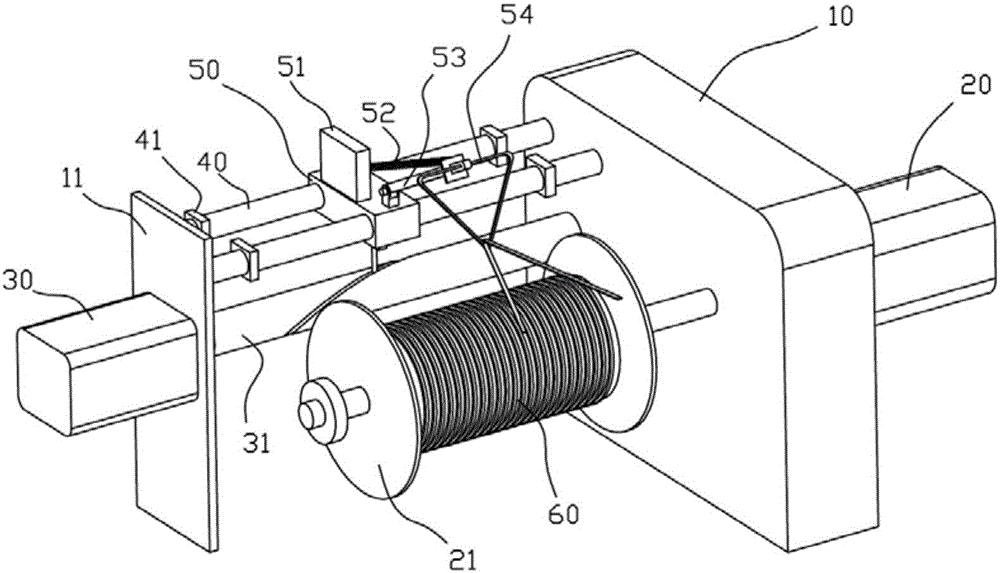

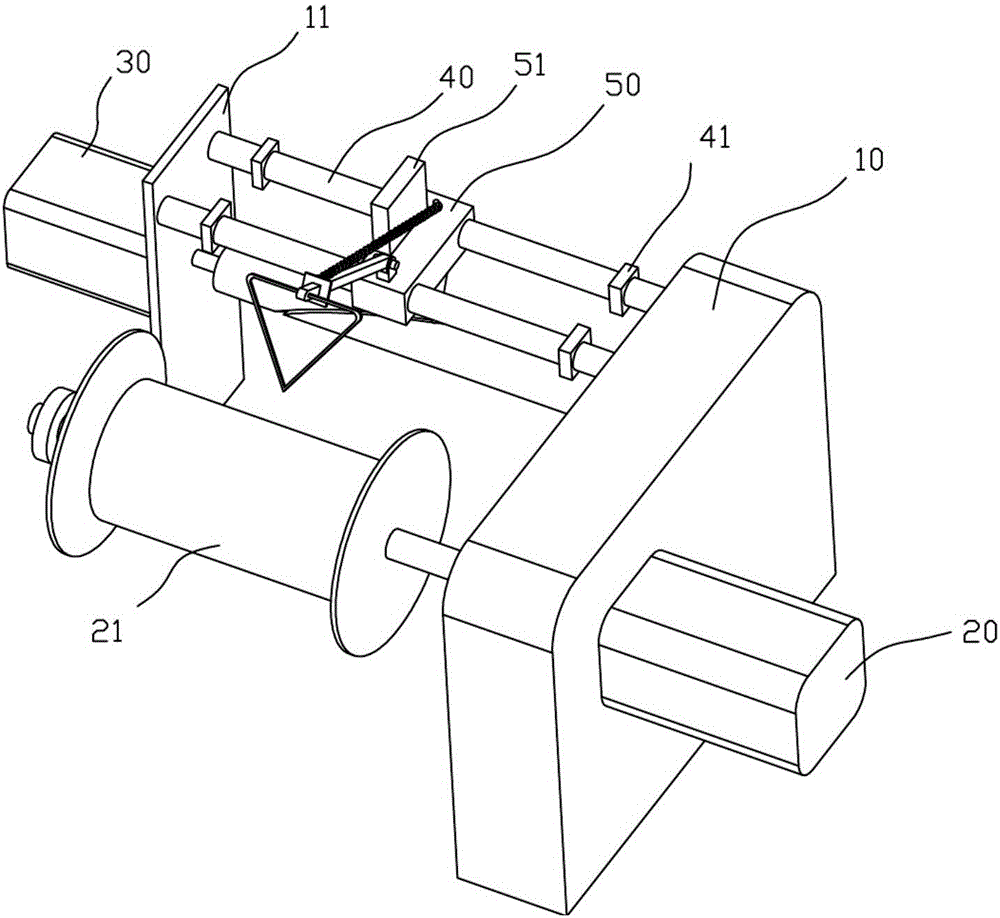

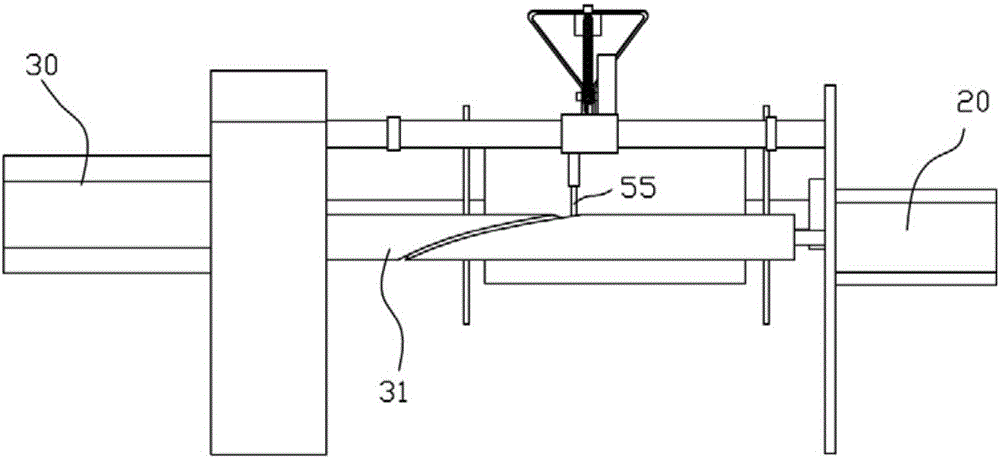

[0023] Such as figure 1 , figure 2 and image 3 As shown, a kind of window film scrap edge automatic storage machine comprises first support 10 and second support 11, and described first support 10 is provided with large motor 20, and described large motor 20 is connected with reel 21; The second support 11 is provided with a small motor 30, the small motor 30 is connected with the driving shaft 31, and the other end of the driving shaft 31 is installed among the first support 10; the first support 10 and the second support 11 Two slide rails 40 are arranged between, and two described slide rails 40 are provided with slide block 50, and described slide block 50 is provided with spring 52 and rotating rod 53, and the end of described spring 52 and rotating rod 53 is connected , the rotating rod 53 is provided with a triangular ring 54 .

[0024] Such as Figure 1 to Figure 4 As shown, a driving lever 55 is provided under the slider 50, and a chute 310 is provided on the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com