Material bag stacking machine

A stacker and material package technology, applied in the field of packaging machinery, can solve the problems of limited stacking height, low work efficiency, high labor intensity, etc., and achieve the effects of easy installation and operation, high production efficiency, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

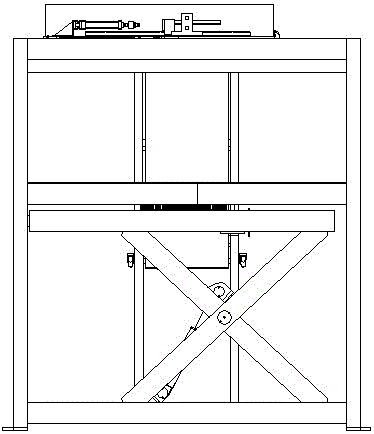

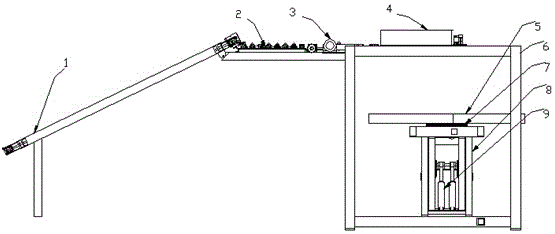

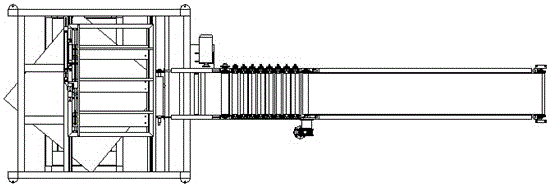

[0021] Embodiment 1, with reference to the accompanying drawings, the working principle of the frame high-level palletizer of the present invention is: the materials enter the climbing conveyor belt with a small gap in the package, and when they are transported to the fast conveyor belt, the materials are sent to the blanking by means of its rapid impact force In the machine, according to the blanking order (first left, then right, and finally the middle), when 3 packs are stacked, the tray rotates 180 degrees to continue blanking, and when 6 packs are stacked in one layer, the pallet rotates 90 degrees (cross-stacking) or rotates 180 degrees Speed (along stacking) and descend a certain distance to make room for the next layer of stacked packages. According to this process, the stacking cycle is repeated until the set number of packs is reached. After the pallet is rotated 90 degrees, the elevator is lowered to the bottom and the sound and light alarm is activated. The stacki...

Embodiment 2

[0022] Embodiment 2. Referring to Embodiment 1 and the accompanying drawings, the scissor lifting arm (8) and the lifting hydraulic cylinder (9) of the blanking mechanism (4) are changed to a gear structure or a worm gear structure, and the rotary displacement platform (5 ) Change the lifting and reset angle to achieve the purpose of stacking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com