Battery out-of-box continuous driving system for electric vehicle and electric vehicle

A technology of electric vehicles and batteries, which is applied in the direction of electric vehicles, battery/battery traction, battery/fuel cell control devices, etc., and can solve the problems of battery packs that cannot be unpacked in time and failure deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Figure 5 The circuit structure of the battery unboxing subsystem 10 in Embodiment 1 of the present invention is shown. In Embodiment 1 of the present invention, each of the out-of-box control units 102 includes a first high-voltage contactor KM1. Wherein, the first high voltage contactor KM1 has a first main contact and a second main contact.

[0128] Wherein, the first main contact of the first high-voltage contactor KM1 is connected to the fourth connection terminal S4 of the unboxing control unit 102, that is, the first main contact of the first high-voltage contactor KM1 is connected to the battery The first connecting end S1 of the unpacking subsystem 10, that is, the first main contact of the first high-voltage contactor KM1 is connected to the second connecting end S2 of the previous adjacent battery unpacking subsystem 10, that is, the first main contact of the first high-voltage contactor KM1. The first main contact of a high-voltage contactor KM1 is connect...

Embodiment 2

[0150] Figure 8 The circuit structure of the battery unboxing subsystem 10 in the second embodiment of the present invention is shown. In the second embodiment, each of the out-of-box control units 102 includes a third high-voltage contactor KM3. Wherein, the third high voltage contactor KM3 has a fifth main contact, a sixth main contact and a seventh main contact.

[0151] Wherein, the fifth main contact is connected to the fourth connection terminal S4 of the unpacking control unit 102, that is, the fifth main contact is connected to the first connection terminal S1 of the battery unpacking subsystem 10, that is, the The fifth main contact is connected to the second connection terminal S2 of the previous adjacent battery unpacking subsystem 10, that is, the fifth main contact is connected to the battery pack 101 in the previous adjacent battery unpacking subsystem 10. The second electrode E2. The sixth main contact is connected to the fifth connection terminal S5 of the ...

Embodiment 3

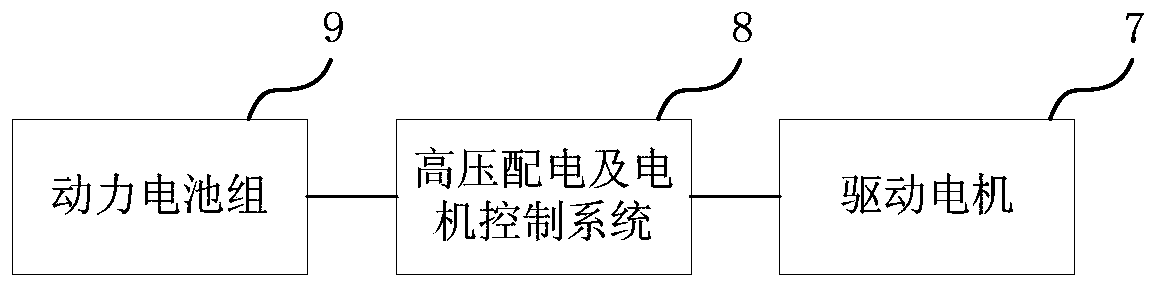

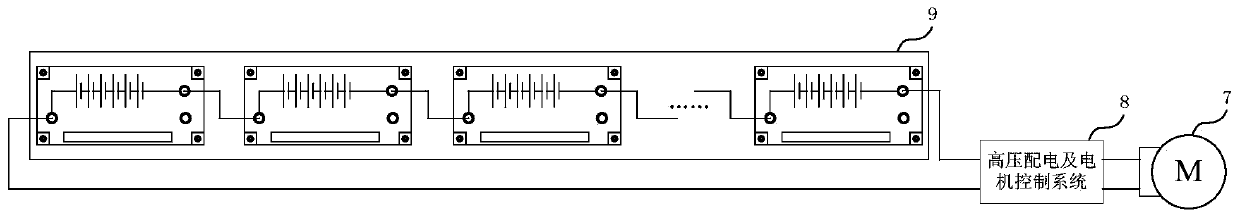

[0184] Such as Figure 13 As shown, different from the previous embodiments, the electric vehicle battery unpacking driving system according to the third embodiment of the present invention includes multiple (at least two) battery unpacking subsystems 10, and each battery unpacking subsystem 10 is connected in parallel. Each of the battery unpacking subsystems 10 includes a battery pack 101 and an unpacking control unit 102 . Wherein, in the battery tow box subsystem 10 , the unpacking control unit 102 is connected in series with the battery pack 101 . In any battery drag box subsystem 10, when the battery pack 101 is in a normal state, the unpacking control unit 102 is connected; when the battery pack 101 is in an abnormal state, the unpacking control unit 102 is disconnected . The electric vehicle battery out-of-box continuous driving system is connected to the high-voltage power distribution and motor control system of the electric vehicle.

[0185] Figure 14 The circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com