Method for preparing stretchable breath detection material

A detection material and pre-stretching technology, which is applied in the field of pre-stretching release to prepare stretchable breathing detection materials, can solve the problems of complex preparation process, high cost, and difficulty in mass production, and achieve simple preparation process and low cost , The effect of simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Step 1, Compounding: Pre-stretch: The viscous rubber VHB substrate is pre-stretched by 300%.

[0026] Step 2, paste: paste the nitrile rubber membrane on the VHB substrate in step 1.

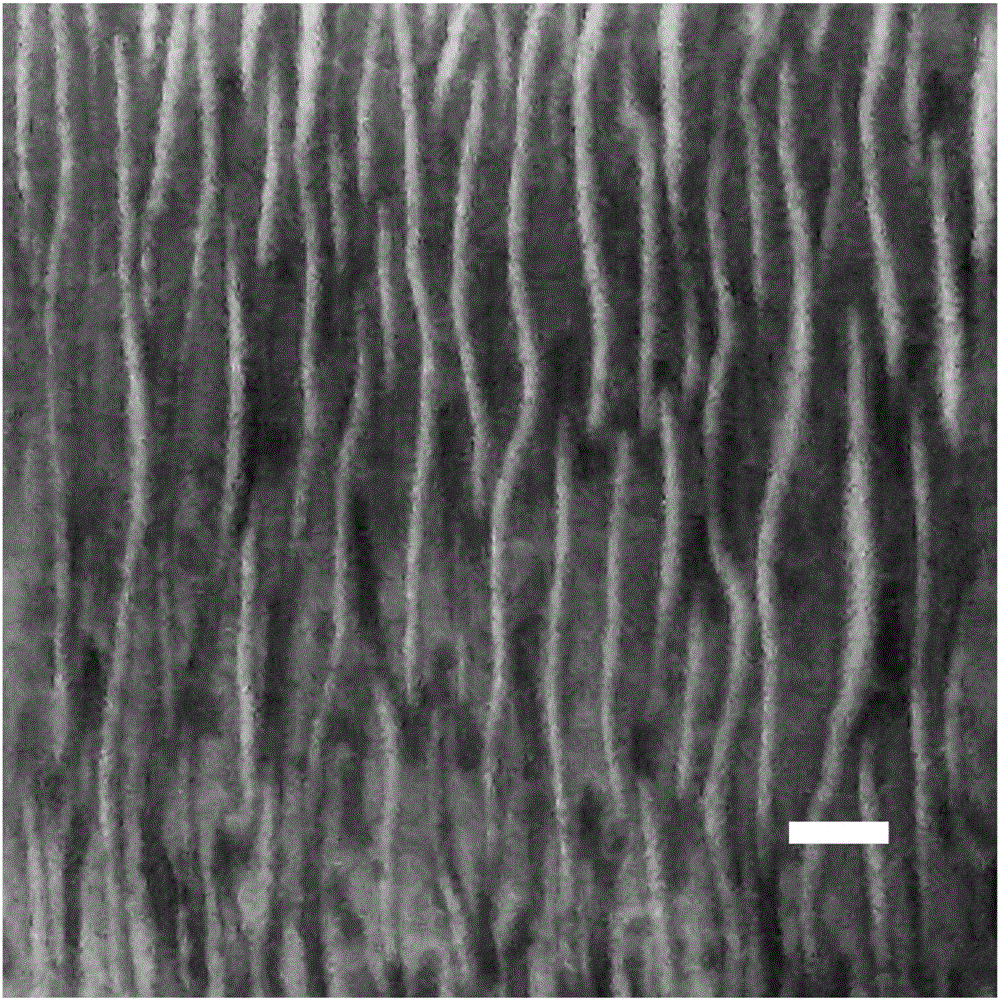

[0027] Step 3, releasing: the strain of the VHB substrate in step 2 is released (forming a wrinkled nitrile rubber film), and a stretched breathing detection material is obtained. The microscopic morphology is shown in Fig. 1(a).

[0028] A digital ammeter was used to test the change of the current signal over time, and the performance of the stretched breathing detection material was obtained as shown in Figure 2(a) (the signal corresponding to weak breathing in the first 30 seconds, and the signal corresponding to strong breathing in the last 30 seconds). Compared with prior art or method, this example is simpler in process (does not involve harsh environment such as high temperature and high pressure, does not have any chemical reaction etc.), raw material cost is lower (does not use ...

example 2

[0030] Step 1, Compounding: Pre-stretching: The viscous rubber VHB substrate is pre-stretched by 200%.

[0031] Step 2, paste: paste the nitrile rubber membrane on the VHB substrate in step 1.

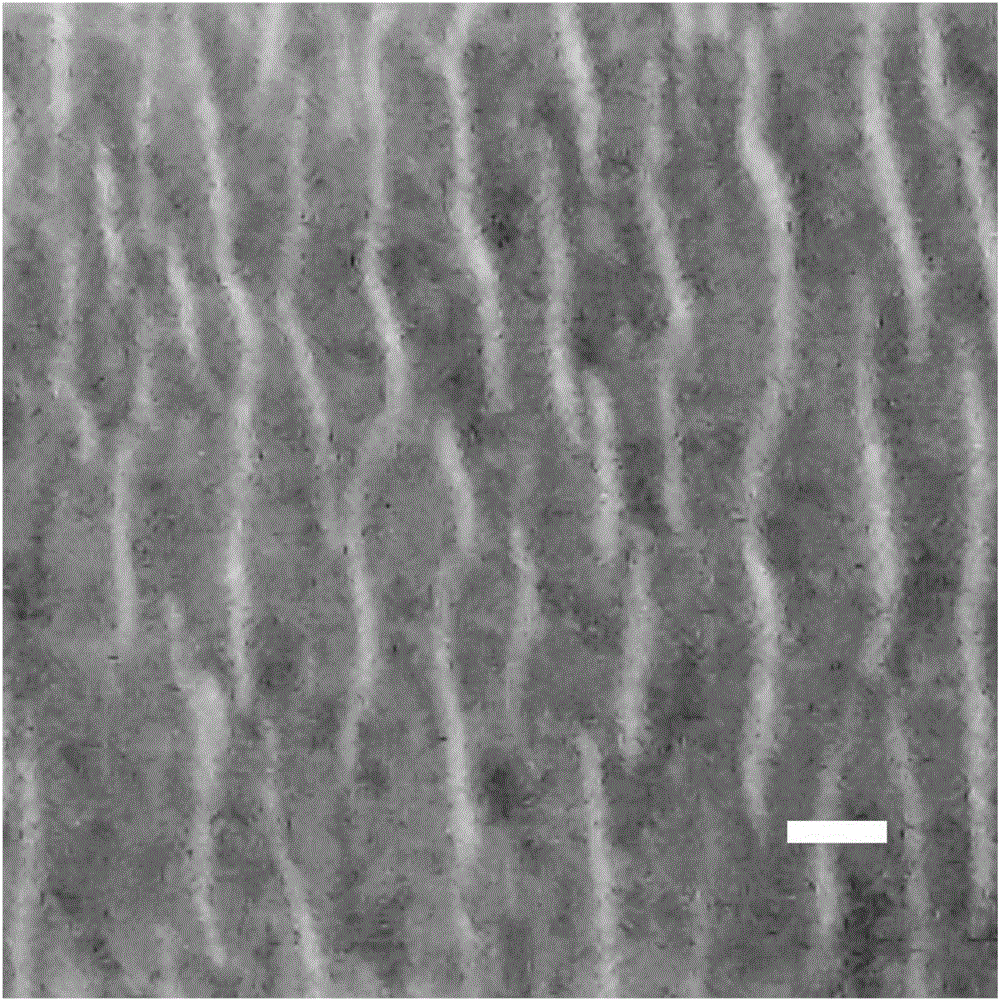

[0032] Step 3, releasing: the strain of the VHB substrate in step 2 is released (forming a wrinkled nitrile rubber film), and a stretched breathing detection material is obtained. The microscopic morphology is shown in Fig. 1(b).

[0033] A digital ammeter was used to test the change of the current signal over time, and the performance of the stretched breathing detection material was obtained as shown in Figure 2(b) (the signal corresponding to weak breathing in the first 30 seconds, and the signal corresponding to strong breathing in the last 30 seconds). Compared with prior art or method, this example is simpler in process (does not involve harsh environment such as high temperature and high pressure, does not have any chemical reaction etc.), raw material cost is lower (does not u...

example 3

[0035] Step 1, Formulation: Pre-stretch: The viscous rubber VHB substrate is pre-stretched by 500%.

[0036] Step 2, paste: paste the nitrile rubber membrane on the VHB substrate in step 1.

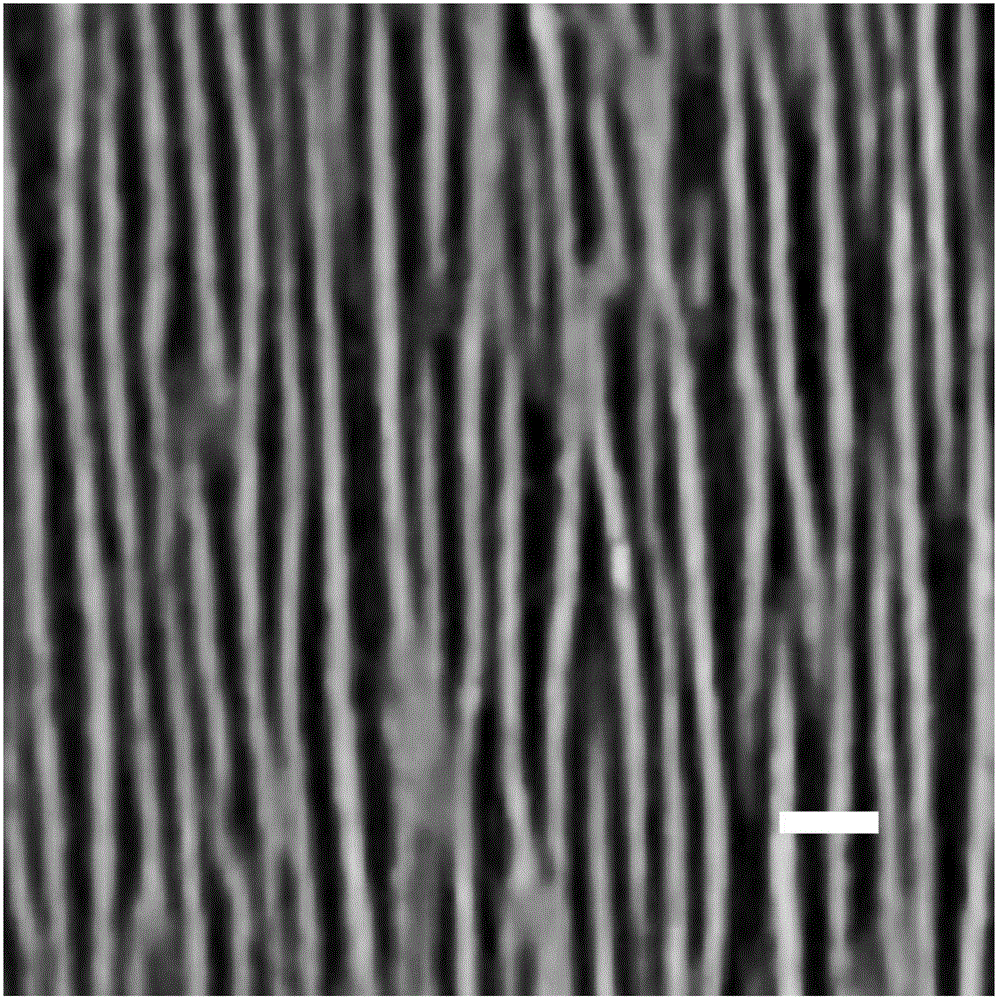

[0037] Step 3, releasing: the strain of the VHB substrate in step 2 is released (forming a wrinkled nitrile rubber film), and a stretched breathing detection material is obtained. The microscopic morphology is shown in Fig. 1(c).

[0038] A digital ammeter was used to test the change of the current signal over time, and the performance of the stretched breathing detection material was obtained as shown in Figure 2(c) (the signal corresponding to weak breathing in the first 30 seconds, and the signal corresponding to strong breathing in the last 30 seconds). Compared with prior art or method, this example is simpler in process (does not involve harsh environment such as high temperature and high pressure, does not have any chemical reaction etc.), raw material cost is lower (does not use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com