Method for preparing high-strength alginate fiber

A seaweed fiber and high-strength technology, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, wet spinning method, etc., can solve the problems of reduction and loss of seaweed fiber mechanical properties, and achieve strong drawability, increased activity, Good effect of anti-degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

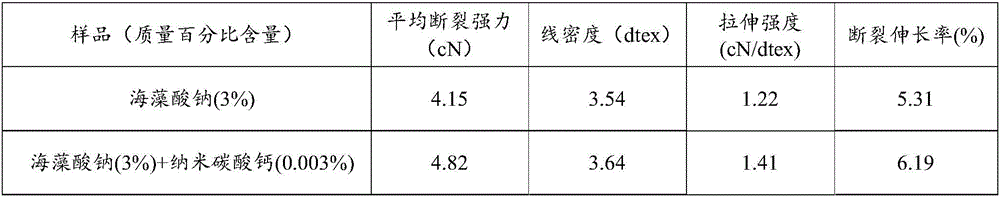

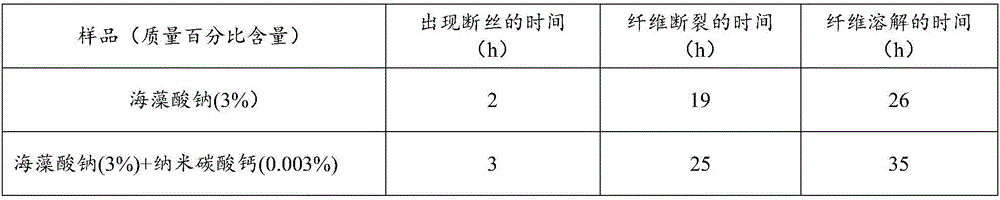

Embodiment 1

[0043] The preparation method includes the following steps:

[0044] In the first step, weigh 3g sodium alginate and 0.003g nano-calcium carbonate at a mass ratio of 100:0.1, and set aside;

[0045] In the second step, add the sodium alginate to 100ml of deionized water to dissolve it, stir at room temperature for 3 hours, then heat to 50°C, continue stirring for 2 hours, and prepare alginic acid with a mass percentage concentration of 3% Sodium solution

[0046] The above sodium alginate solution was divided into two parts A and B according to a ratio of 1:5, 0.003g of nano calcium carbonate was added to part A, and the mixture was continuously stirred for 3 hours at room temperature and then sonicated for 0.5 hours to obtain a mixed solution;

[0047] Then, adding part B to the above-mentioned mixed solution and stirring evenly to prepare nano-calcium carbonate-sodium alginate spinning dope;

[0048] In the third step, the obtained nano-calcium carbonate-sodium alginate spinning dope...

Embodiment 2

[0060] The preparation method includes the following steps:

[0061] In the first step, weigh 5g of sodium alginate and 0.0.025g of nano-calcium carbonate at a mass ratio of 100:0.5, and set aside;

[0062] In the second step, dissolve the sodium alginate taken in water, stir at room temperature for 4 hours, then heat to 50°C, continue stirring for 3.5 hours, and prepare a sodium alginate solution with a concentration of 5% by mass;

[0063] Divide the sodium alginate solution into two parts A and B according to the ratio of 1:4, add 0.025 g of nano calcium carbonate to part A, continue to stir at room temperature for 3 hours, and then ultrasonically treat for 1 hour to obtain a mixed solution;

[0064] Then, adding part B to the above-mentioned mixed solution and stirring evenly to prepare nano-calcium carbonate-sodium alginate spinning dope;

[0065] In the third step, the obtained nano-calcium carbonate-sodium alginate spinning dope was filtered and quickly defoamed under a vacuum of...

Embodiment 3

[0078] The preparation method includes the following steps:

[0079] In the first step, weigh 7g of sodium alginate and 0.07g of nano-calcium carbonate at a mass ratio of 100:1, and set aside;

[0080] In the second step, dissolve the sodium alginate taken in water, stir at room temperature for 5 hours, then heat to 50°C, continue stirring for 4 hours, and prepare a sodium alginate solution with a concentration of 7% by mass;

[0081] Divide the sodium alginate solution into parts A and B according to the ratio of 1:4, add 0.07 g of nano calcium carbonate to part A, continue to stir at room temperature for 3 hours, and then ultrasonically treat for 1.5 hours to obtain a mixed solution;

[0082] Then, add part B to the above-mentioned mixed solution and stir evenly to prepare nano-calcium carbonate-sodium alginate spinning dope;

[0083] In the third step, the obtained nano-calcium carbonate-sodium alginate spinning dope is filtered and quickly defoamed under a vacuum of 100 Pa. The temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com