High-sensitivity stretchable flexible strain sensor and preparation method thereof

A strain sensor, flexible technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of low stretchability, low sensitivity, poor stability, etc., achieve simple preparation method, improve Sensing performance, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a flexible strain sensor and a preparation method thereof, the method comprising the following steps:

[0073] (1)'Urethane sponge (thickness 0.8mm, length 20mm, width 10mm) is repeatedly washed with deionized water and absolute ethanol, and then dried;

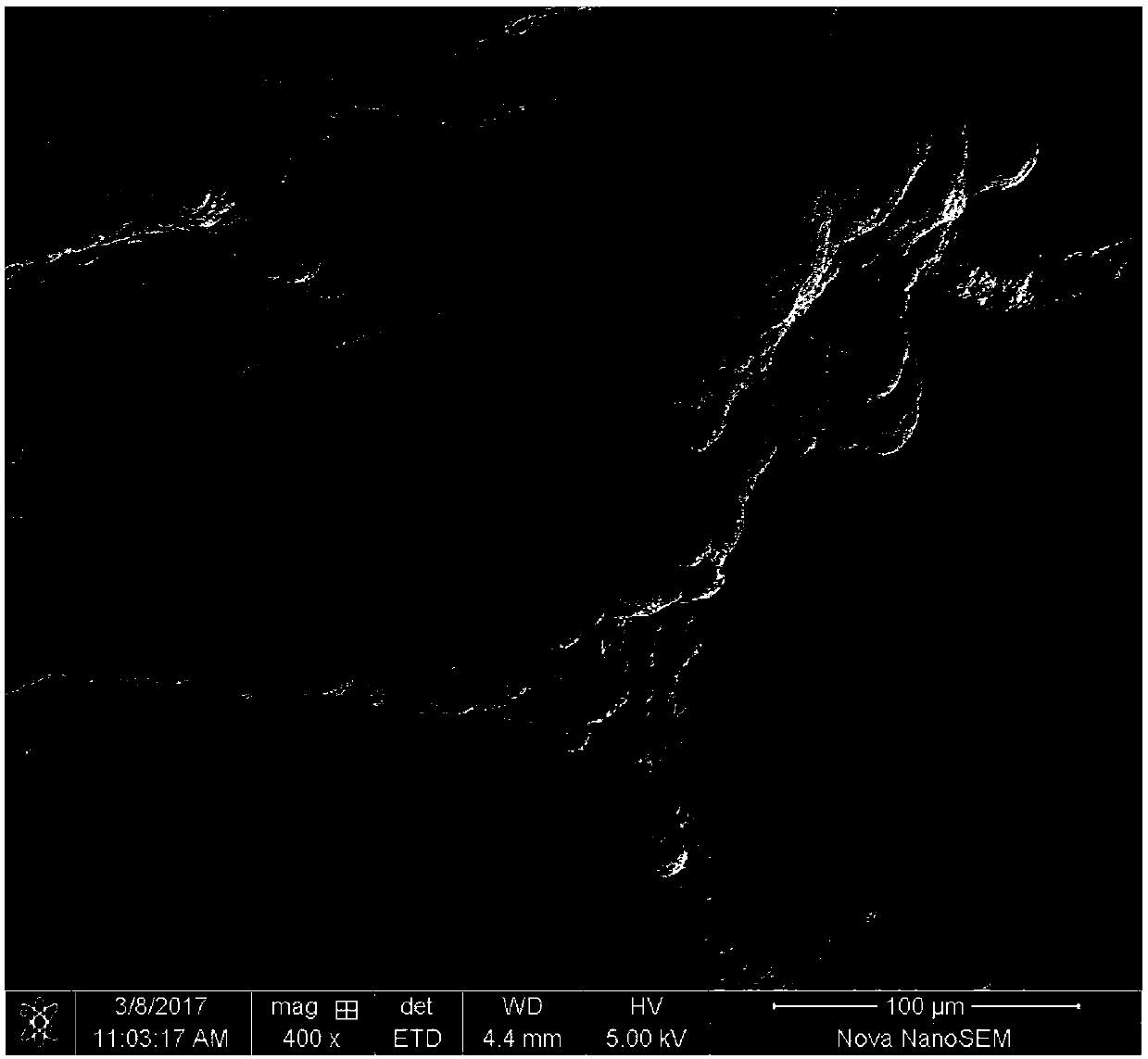

[0074] (1) Soak the dried polyurethane sponge in a graphene solution for 4 hours, and then use hot hydroiodic acid to reduce the polyurethane sponge soaked with graphene oxide at 85°C for 12 minutes in a water bath. The concentration of the solution is calibrated as follows: make the volume ratio of hydriodic acid to deionized water in the solution of graphene oxide be 1:1, dry, then repeat the above-mentioned steps of soaking, reducing and drying for 4 times successively, and repeat the last time After time-reduction, it is washed with deionized water and then dried to obtain a graphene-coated polyurethane sponge;

[0075] (2) the graphene-coated polyurethane sponge described in step (1) is u...

Embodiment 2

[0081] (1)'Urethane sponge (thickness 1mm, length 25mm, width 10mm) is repeatedly washed with deionized water and absolute ethanol, and then dried;

[0082] (1) Soak the dried polyurethane sponge in a graphene solution for 3 hours, and then use hot hydroiodic acid to reduce the polyurethane sponge soaked with graphene oxide at 90°C for 10 minutes in a water bath. The concentration of the deionized water is calibrated as follows: make the volume ratio of hydriodic acid to deionized water in the solution of graphene oxide be 1:2, dry, then repeat the above-mentioned steps of soaking, reducing and drying for 3 times successively, and repeat the last time After time-reduction, it is washed with deionized water and then dried to obtain a graphene-coated polyurethane sponge;

[0083] (2) the graphene-coated polyurethane sponge described in step (1) is used as the cathode, the nickel foil is the anode, and the NiCl 2 ·6H 2 O, H 3 BO 3 and a mixed solution of ethylenediamine dihyd...

Embodiment 3

[0087] (1) 'Polyurethane sponge (thickness 1.5mm, length 30mm, width 15mm) is repeatedly washed with deionized water and absolute ethanol, and then dried;

[0088] (1) Soak the dried polyurethane sponge in a graphene solution for 5 hours, and then use hot hydroiodic acid to reduce the polyurethane sponge soaked with graphene oxide at 85°C for 10 minutes in a water bath. The concentration of the solution is calibrated as follows: make the volume ratio of hydriodic acid to deionized water in the solution of graphene oxide be 1:5, dry, then repeat the above-mentioned steps of soaking, reducing and drying twice successively, and repeat the last time After time-reduction, it is washed with deionized water and then dried to obtain a graphene-coated polyurethane sponge;

[0089] (2) the graphene-coated polyurethane sponge described in step (1) is used as the cathode, the nickel foil is the anode, and the NiCl 2 ·6H 2 O, H 3 BO 3 and a mixed solution of ethylenediamine dihydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com