Multi-station separate and fine manufacturing complete device for motorcycle yoke plate

A complete set of equipment, multi-station technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of increasing the batch production cycle, waste of machine tool resources, time, and resources, so as to avoid workpiece waiting time or machine tool. Free time, saving processing and clamping time, guaranteeing the effect of the size of the processing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

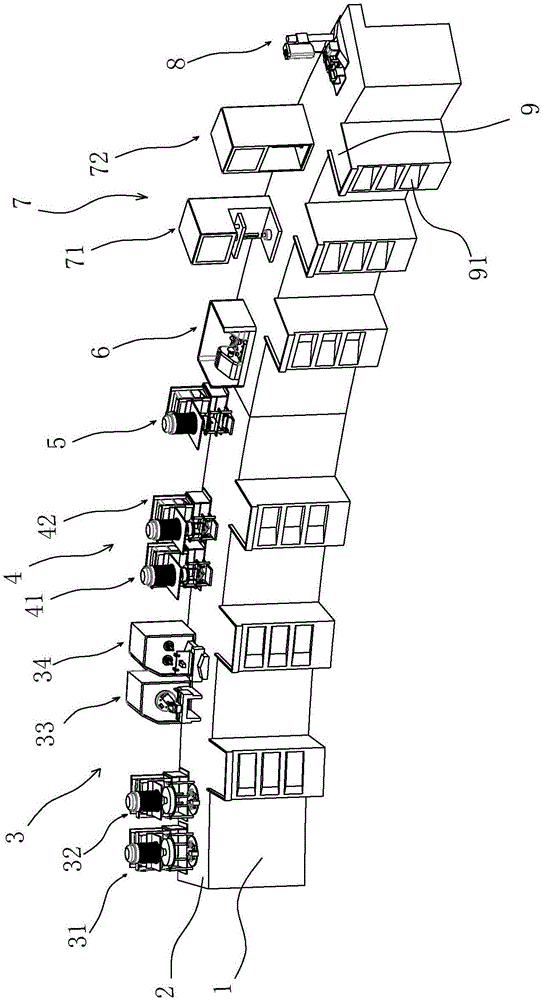

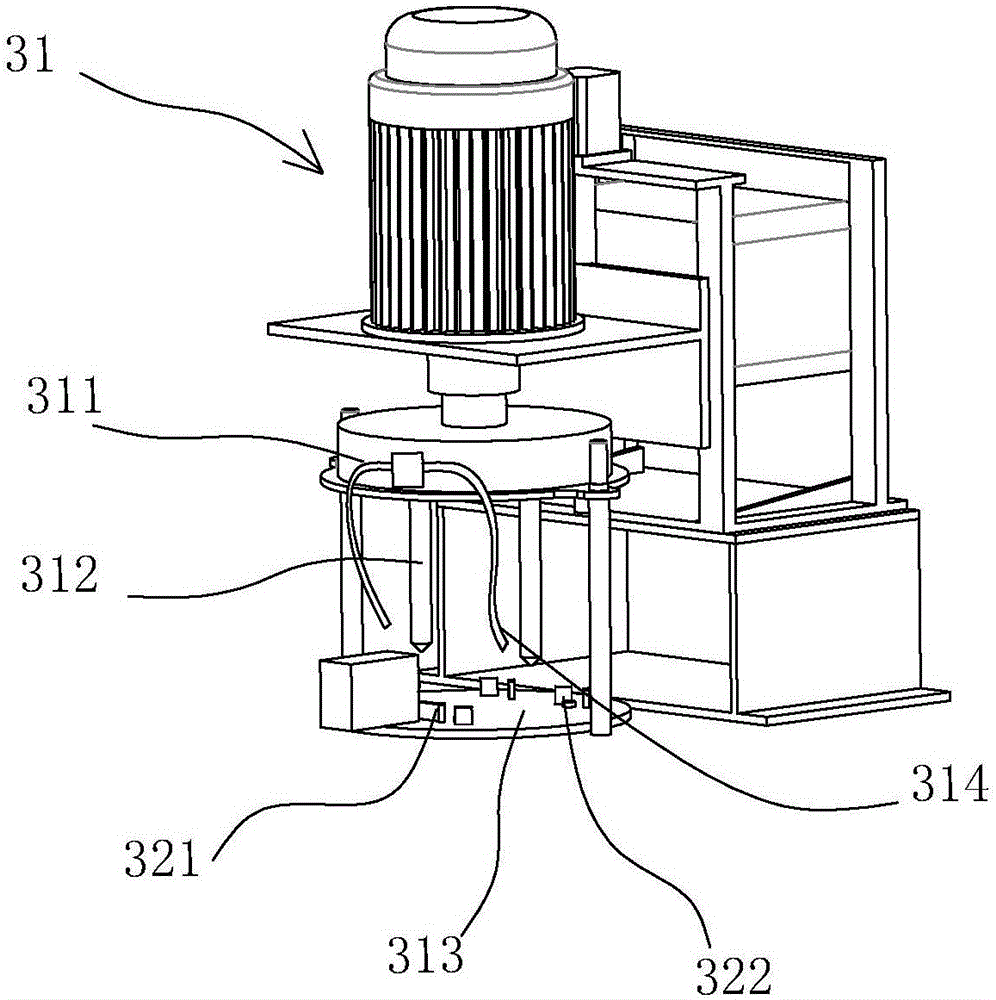

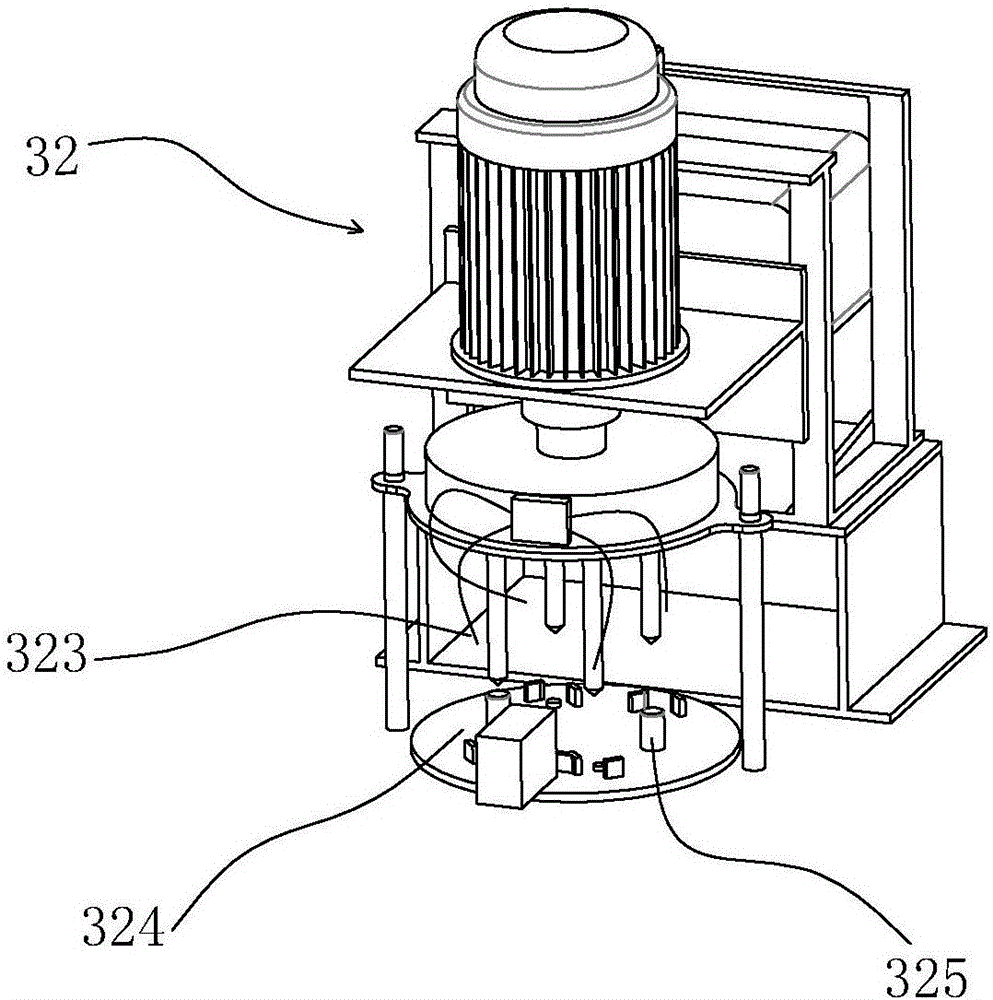

[0036] Such as figure 1 As shown in the figure, a complete set of multi-station split refined equipment for the lower connecting plate of a motorcycle includes a frame 1, an arc-shaped turntable 2 for placing products is arranged on the top of the frame 1, and three turnstiles are arranged on the outside of the top of the turntable 2. Large hole processing component 3, threaded hole processing component 4, small hole drilling platform 5, side hole breaching component 6, press fit component 7 and direction column drilling platform 8, a quality inspection platform 9 is arranged on the inner side of the top of the turnover platform 2, and the turnover The inner wall of platform 2 is provided with a turnover box 91 for defective products.

[0037]Among them, a quality inspection platform 9 can be set between each processing component acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com