Locomotive steering frame transportation base for railways

A locomotive bogie, railway technology, applied in transportation and packaging, external frame, assembly machine, etc., can solve the problems of easy damage to the bogie, long transportation time, low transportation efficiency, etc., to improve transportation efficiency, reduce transportation costs, The effect of reducing shipping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

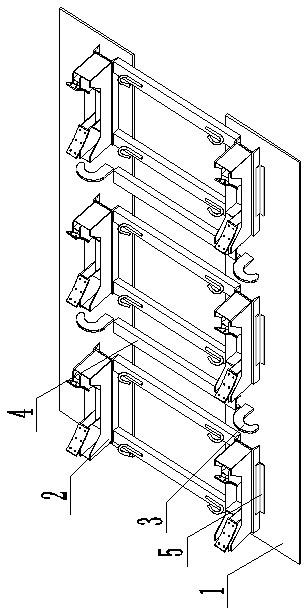

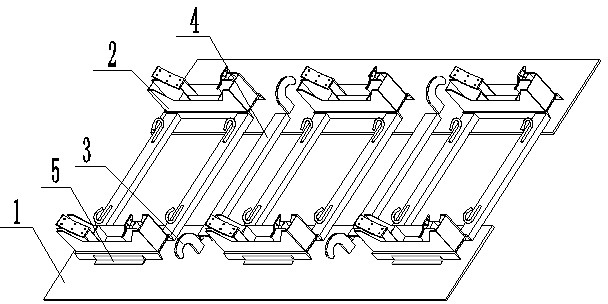

[0014] Such as figure 1 It is a schematic structural diagram of the present invention. A railway locomotive bogie transportation base includes a bottom plate 1, a wheel set transport device 2, a hoisting hook 3, a long channel steel 4, and an angle steel 5. The bottom plate 1 is provided with 3 wheel sets for transportation In the device 2, two lifting hooks 3 are arranged between the wheel set transportation devices 2 and a long channel steel 4 is arranged between the lifting hooks 3, and the two sides of the wheel set transportation device 2 are fixed on the bottom plate 1 through angle steels 5.

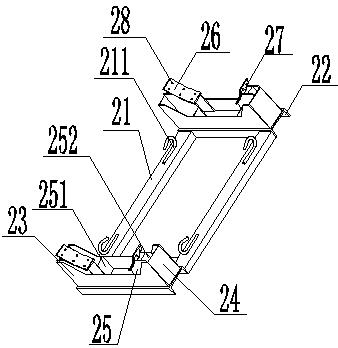

[0015] Such as figure 2 It is a schematic diagram of the structure of the wheel set transportation device of the present invention. The wheel set transportation device 2 is composed of a long channel steel 21, a short channel steel 22, a side plate 23, a connecting plate 24, an arc plate 25, a rubber pad 26, a contour pad 27, and a cross Slotted countersunk head screw 28, hook 211, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com