Small mobile welding robot

A welding robot, robot technology, applied in the direction of welding rod characteristics, supporting electrode clamp device, electrode supporting device, etc., to achieve the effect of convenient use, small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

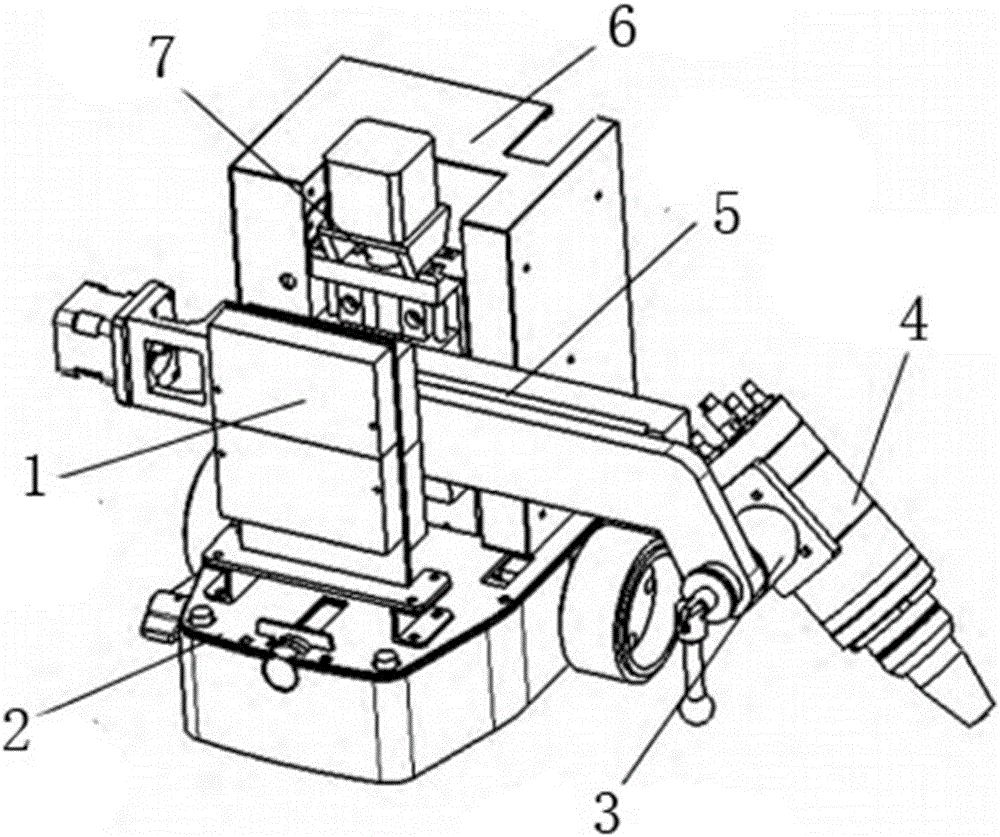

[0013] Such as figure 1 As shown, the present invention provides a small mobile welding robot, including a wheeled mobile platform 2, a welding torch adjustment mechanism, and an arc sensor 4. The wheeled mobile platform adopts a differentially driven three-wheel structure, and two driving wheels are arranged at the rear of the robot. , constitutes the working plane with the front universal wheel to ensure that the robot can move reliably on the workpiece; the two driving wheels are independently driven by two stepping motor drive systems, and the trajectory planning and tracking of the robot are realized through different speed controls. Installed on the front of the robot An ultrasonic ranging sensor prevents the robot from colliding with the workpiece in front; at the same time, it is used to detect the distance between the robot and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com