Grooving equipment for air-entrapping concrete block wall

A technology for slotting equipment and concrete block walls, which is applied in metal processing equipment, drilling/drilling equipment, portable drilling rigs, etc. and other problems, to achieve the effect of low cost, easy portability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

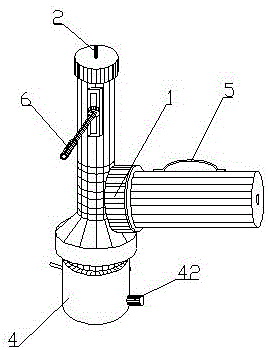

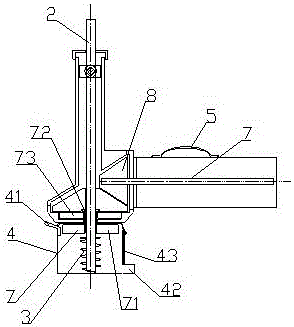

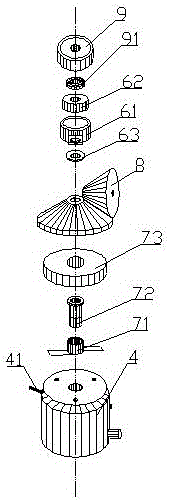

[0023] see figure 1 and Figure 5 , the present invention is an aerated concrete block wall slotting equipment, comprising an "L"-shaped shell 1, a drill shaft 2 runs through the vertical part of the shell 1, the bottom end of the drill shaft 2 is a drill bit 3, and the drill bit 3 Protruding from the bottom end of the vertical part of the housing 1, a protective cover 4 is provided on the outside of the drill bit 3, a handle 5 is provided on the upper side of the horizontal part of the housing 1; a handle 6 is provided on the vertical part of the housing 1 , the handle 6 passes through the housing 1 and is connected to the upper part of the drill shaft 2;

[0024] A motor 7 is arranged in the horizontal part of the housing 1 , and the output shaft of the motor 7 is linked with the drill shaft 2 through the bevel gear set 8 .

[0025] A fan 7 is arranged in the protective cover 4 , and the fan 7 is arranged on the top inside the protective cover 4 . .

[0026] The bevel ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com