Automatic adjusting device and method for vibration frequency of vibrating screen

A technology of automatic adjustment and vibration frequency, which is applied in chemical instruments and methods, sieving, solid separation, etc., can solve the problems that the ability of grain sieving can not be significantly improved, automatic adjustment of vibrating sieve, complex operating environment, etc., to achieve improved sieving capacity, improved cleaning performance, labor-saving and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

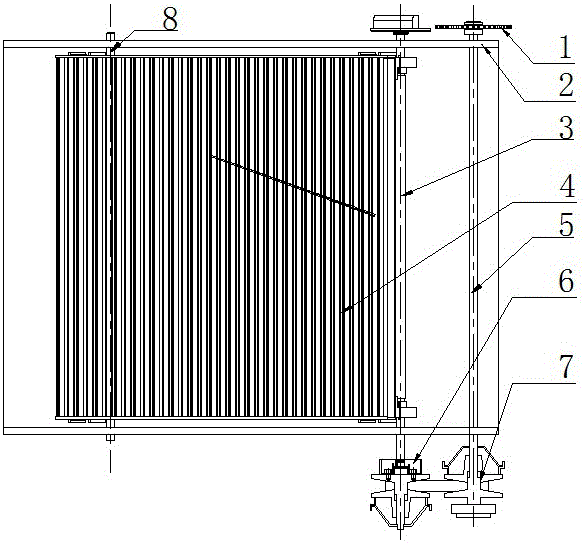

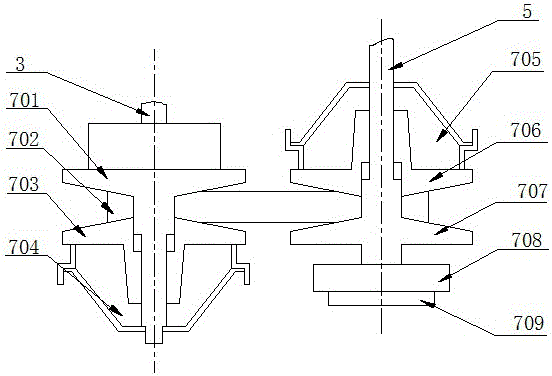

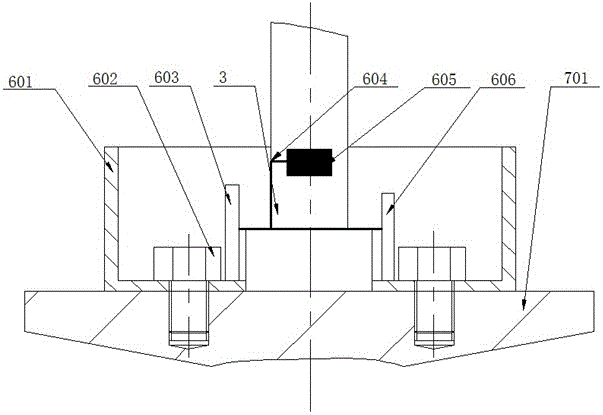

[0021] The specific implementation process of a vibrating screen vibration frequency automatic adjustment device and adjustment method of a specific model of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 1 As shown, an automatic adjustment device and adjustment method for vibration frequency of a vibrating screen, including a driving sprocket 1, a frame 2, a driving shaft 3, a vibrating screen 4, a driving shaft 5, a torsional stress testing system 6, and a continuously variable transmission device 7. Auxiliary driven shaft 8 and signal receiving and processing system 9; driving shaft 5 is installed on the frame 2 through a bearing, and one end is equipped with a driving sprocket 1 through a key, and the power is transmitted to the driving shaft 5 through the sprocket, and the other The active working part of the continuously variable transmission device 7 is installed at one end; the driving and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com